A kind of brazing method of titanium-steel plate butt joint with dual heat sources and low heat input

A brazing method and dual heat source technology, applied in the direction of welding/welding/cutting articles, welding equipment, manufacturing tools, etc., can solve the problem that it is difficult to effectively suppress Ti-Fe brittle compounds, it is difficult to suppress Ti-Fe intermetallic compounds, and it is difficult to obtain Reliable performance Titanium-steel joints and other issues, to achieve the effect of inhibiting the formation of brittle compounds, efficient and reliable connection, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

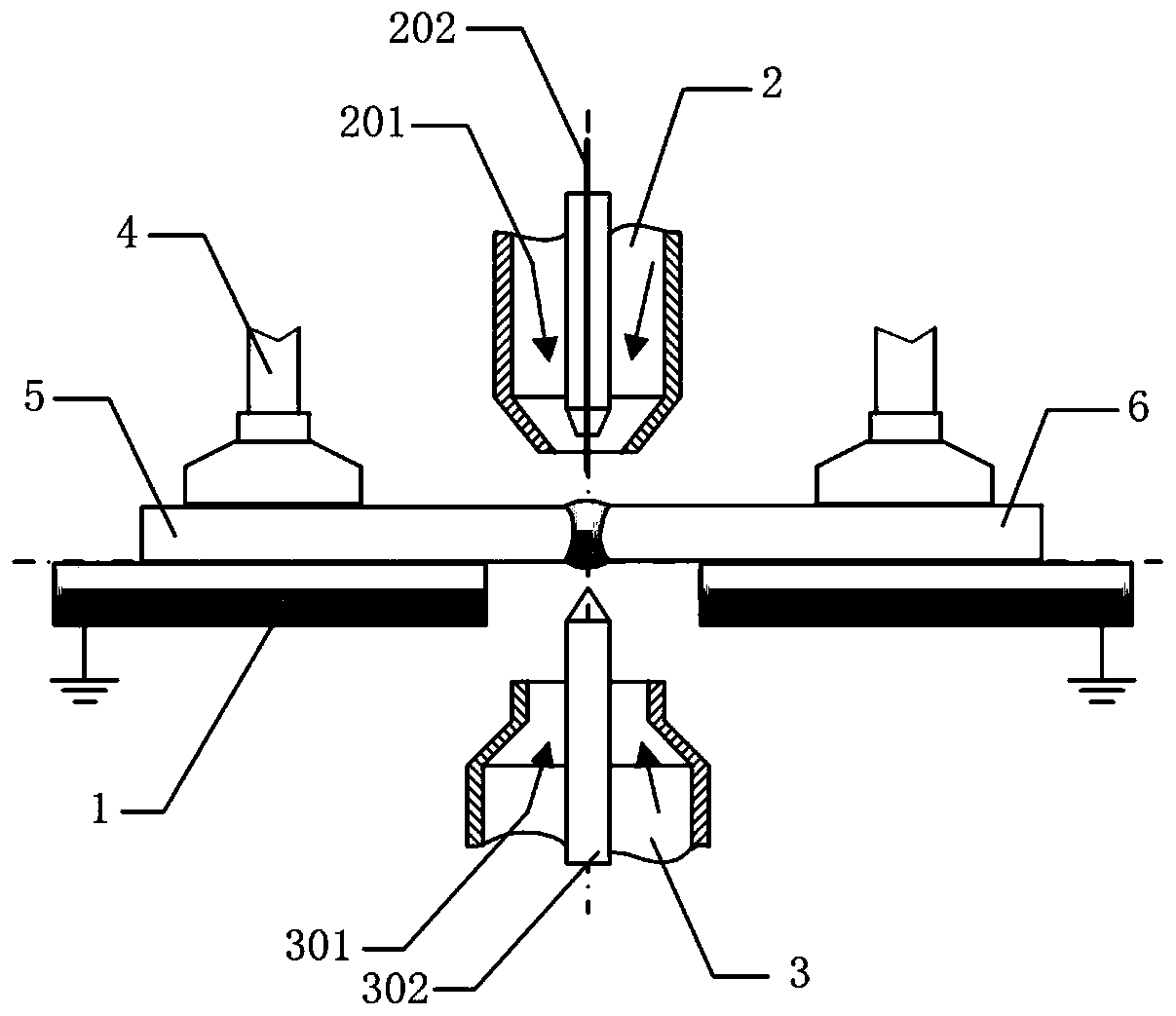

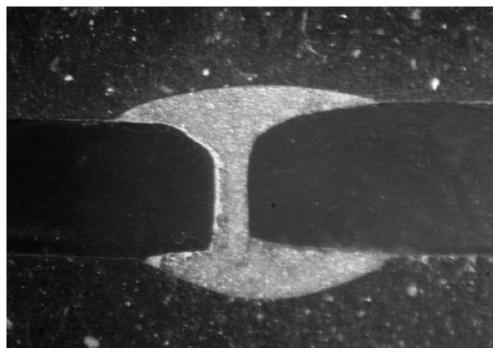

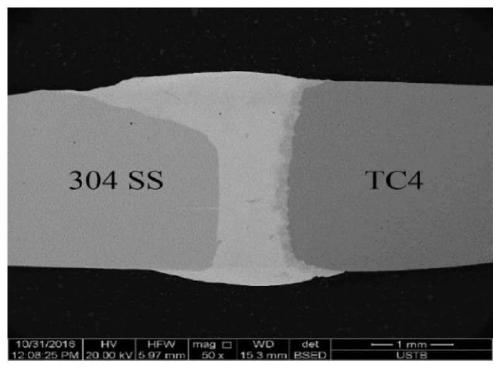

[0032] Such as figure 1As shown, in this example, dual heat sources are used to heat the front and back of the joint at the same time, and the synergistic effect of the dual heat sources acting on the same molten pool is used to reduce the welding heat input, and to improve the energy distribution of the joint by controlling the energy parameters and position parameters of the two heat sources , to achieve a pure brazing connection of titanium-steel. The selected welding base materials are commercial TC4 (Ti6Al4V) plate and 304ss (1Cr18Ni9Ti) plate, both of thickness are 2mm, and the dual heat sources are MIG welding heat source (front heat source) and tungsten inert gas welding Welding heat source (reverse heat source); the front heat source is responsible for heating the workpiece, filling wire and providing gas protection, and the power supply adopts DC reverse connection; the reverse heat source is responsible for heating and gas protection on the back of the workpiece, an...

specific Embodiment 2

[0041] Such as figure 1 As shown, in this example, dual heat sources are used to heat the front and back of the joint at the same time, and the synergistic effect of the dual heat sources acting on the same molten pool is used to reduce the welding heat input, and to improve the energy distribution of the joint by controlling the energy parameters and position parameters of the two heat sources , to achieve titanium-steel brazing connection. The selected welding base metals are commercial TC4 (Ti6Al4V) plate and 304ss (1Cr18Ni9Ti) plate, both of thickness are 3mm, and the dual heat sources are melting inert gas shielded welding heat source (front heat source) and tungsten inert gas shielded welding Welding heat source (reverse heat source); the front heat source is responsible for heating the workpiece, filling wire and providing gas protection, and the power supply adopts DC reverse connection; the reverse heat source is responsible for heating and gas protection on the back ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com