Automatic perforating equipment for bills

A kind of punching equipment and ticket technology, which is applied to the device for coating liquid on the surface, metal processing, coating, etc., can solve the problems of inaccurate punching, non-punching, low punching efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

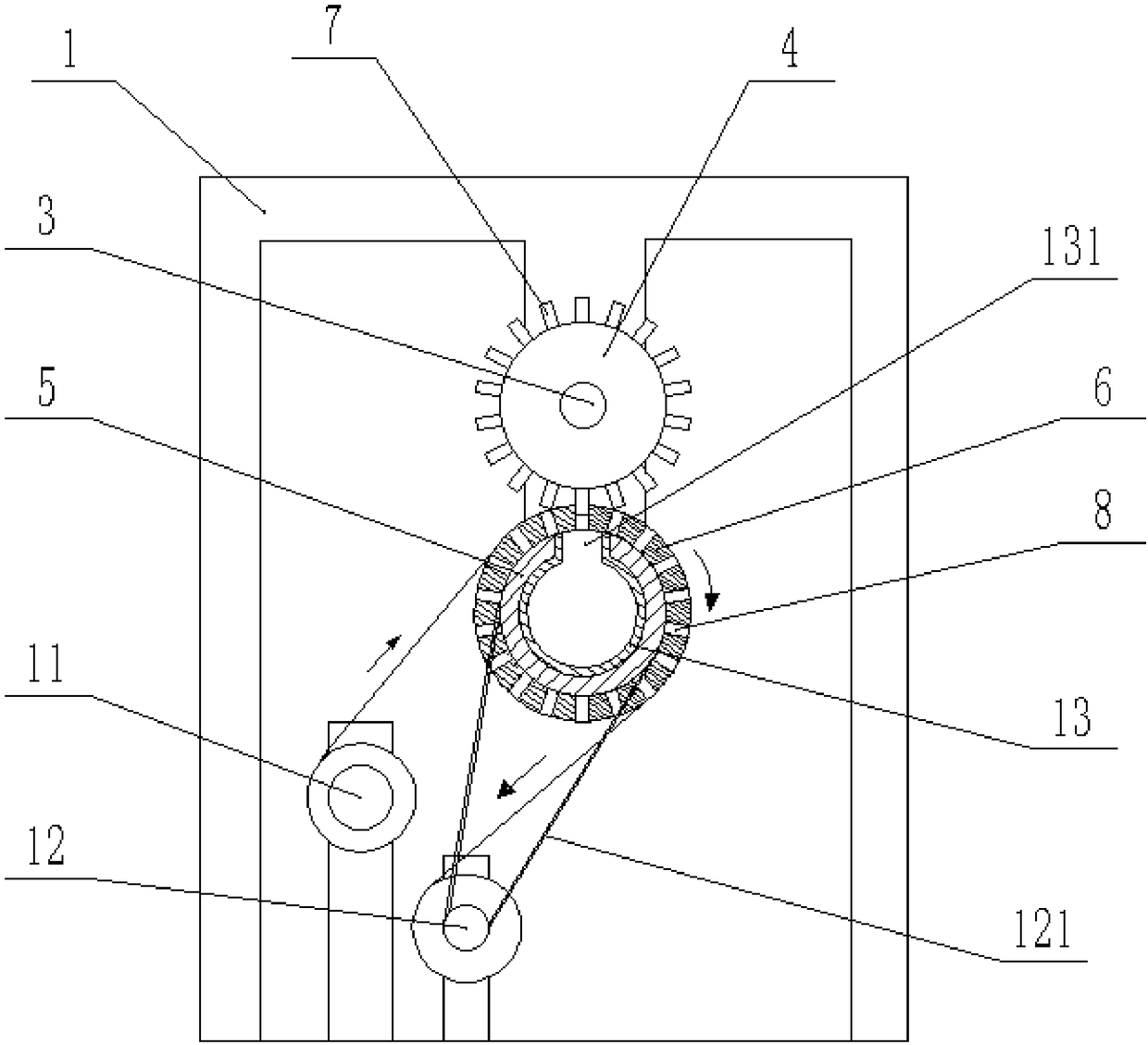

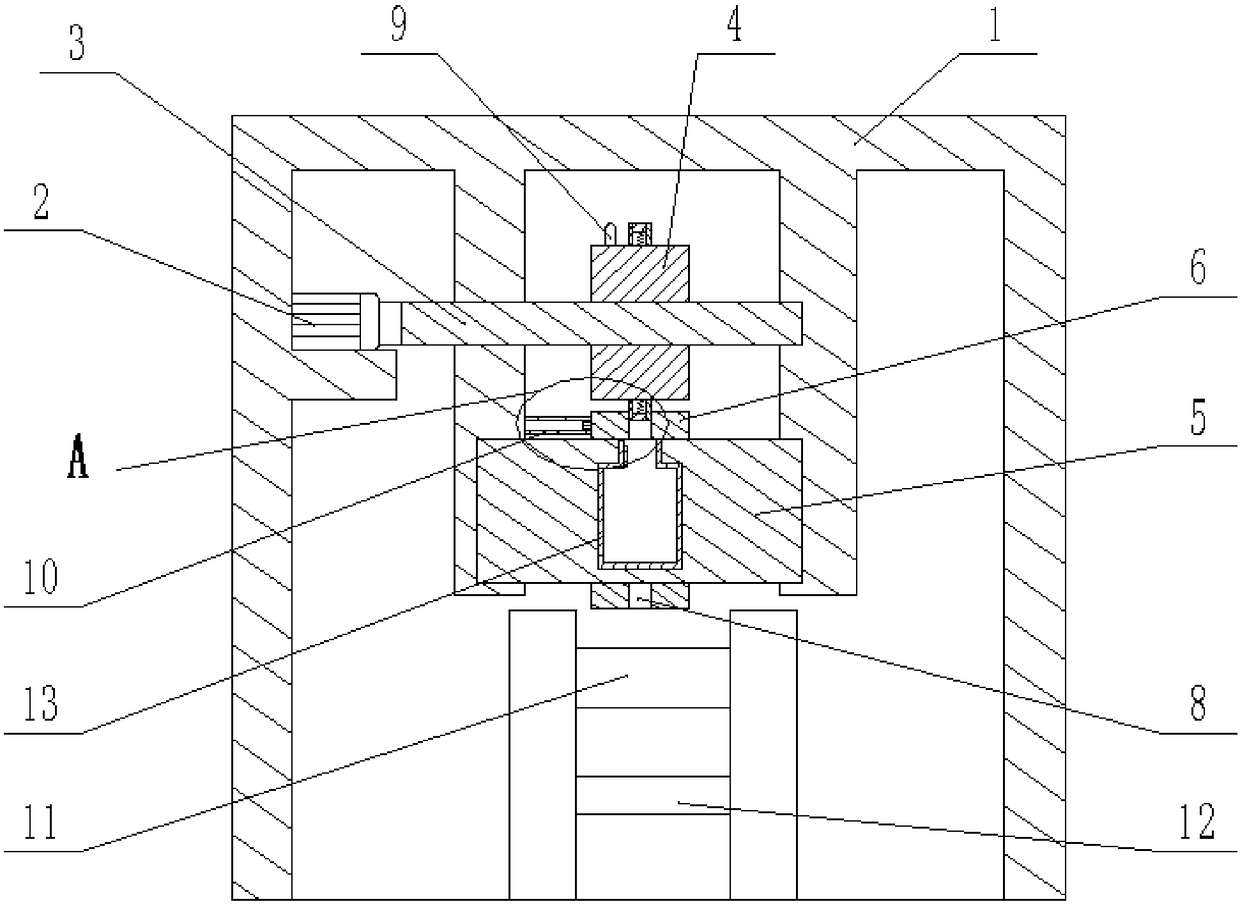

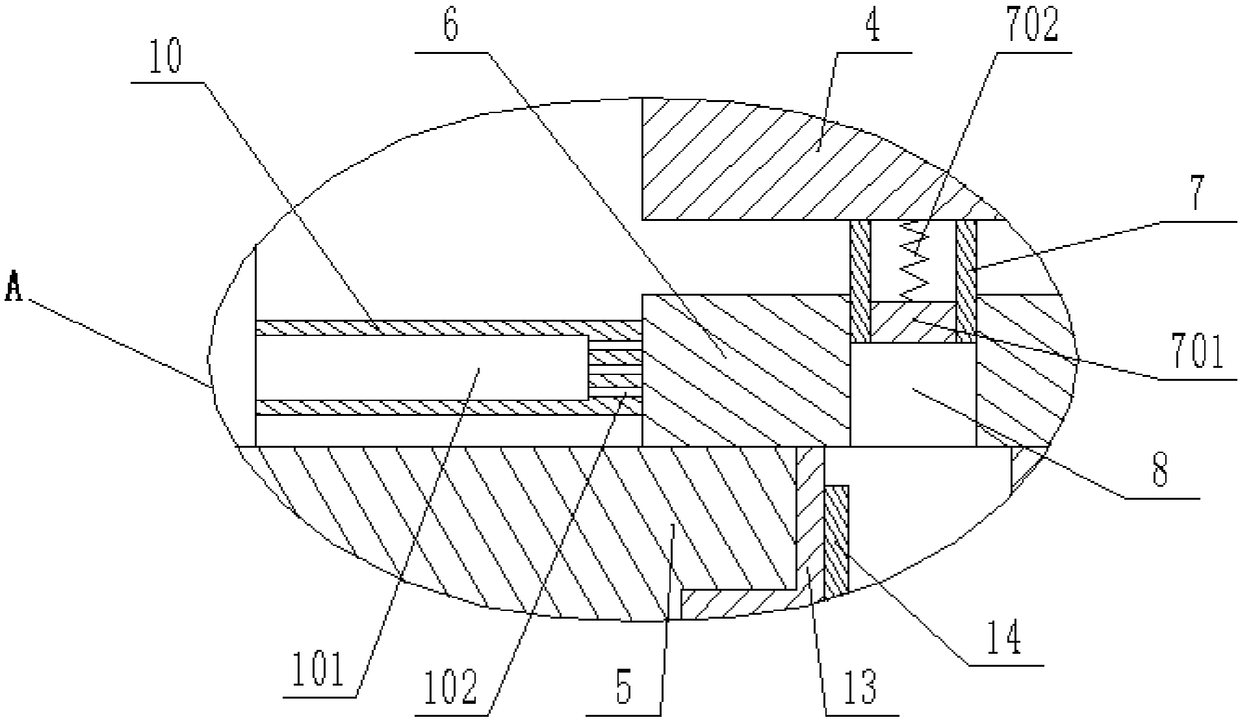

[0019] The reference signs in the drawings of the description include: frame 1, motor 2, first rotating shaft 3, punching disk 4, second rotating shaft 5, punching ring 6, punching head 7, push block 701, extension spring 702, Drilling channel 8, marking pen 9, gluing shaft 10, cavity 101, glue outlet 102, paper feed roller 11, paper delivery roller 12, belt 121, collection box 13, collection port 131, electromagnet 14.

[0020] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 shown, among them, attached figure 1 Middle second rotating shaft 5 and perforated ring 6 take vertical plane as cutting plane, attach figure 2 The Nakamoto device takes the vertical plane where the 3 axes of the first rotating shaft are located as the cutting plane:

[0021] Automatic punching equipment for bills, including a frame 1, a punching unit, a gluing u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com