High-efficiency precise cutting and drilling integrated machine and control method

An all-in-one machine, precise technology, applied in the direction of manufacturing tools, multi-purpose machinery, wood processing equipment, etc., can solve the problem of inability to meet the consistency of electric drill and wood processing, the cutting depth of wood cannot be controlled, and the oblique cutting of wood cannot be realized and other issues, to achieve consistent goals, smooth slopes, and creative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

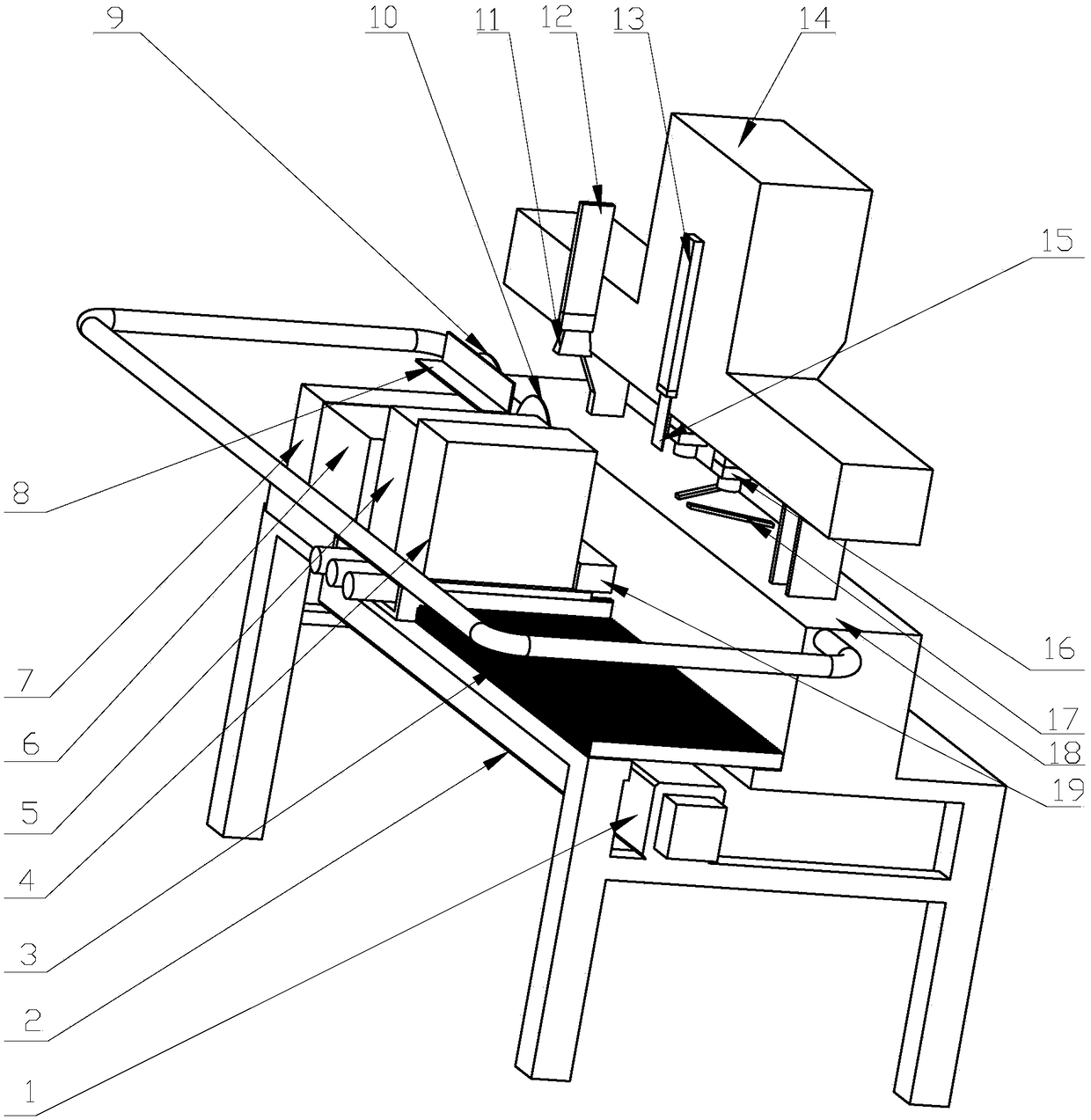

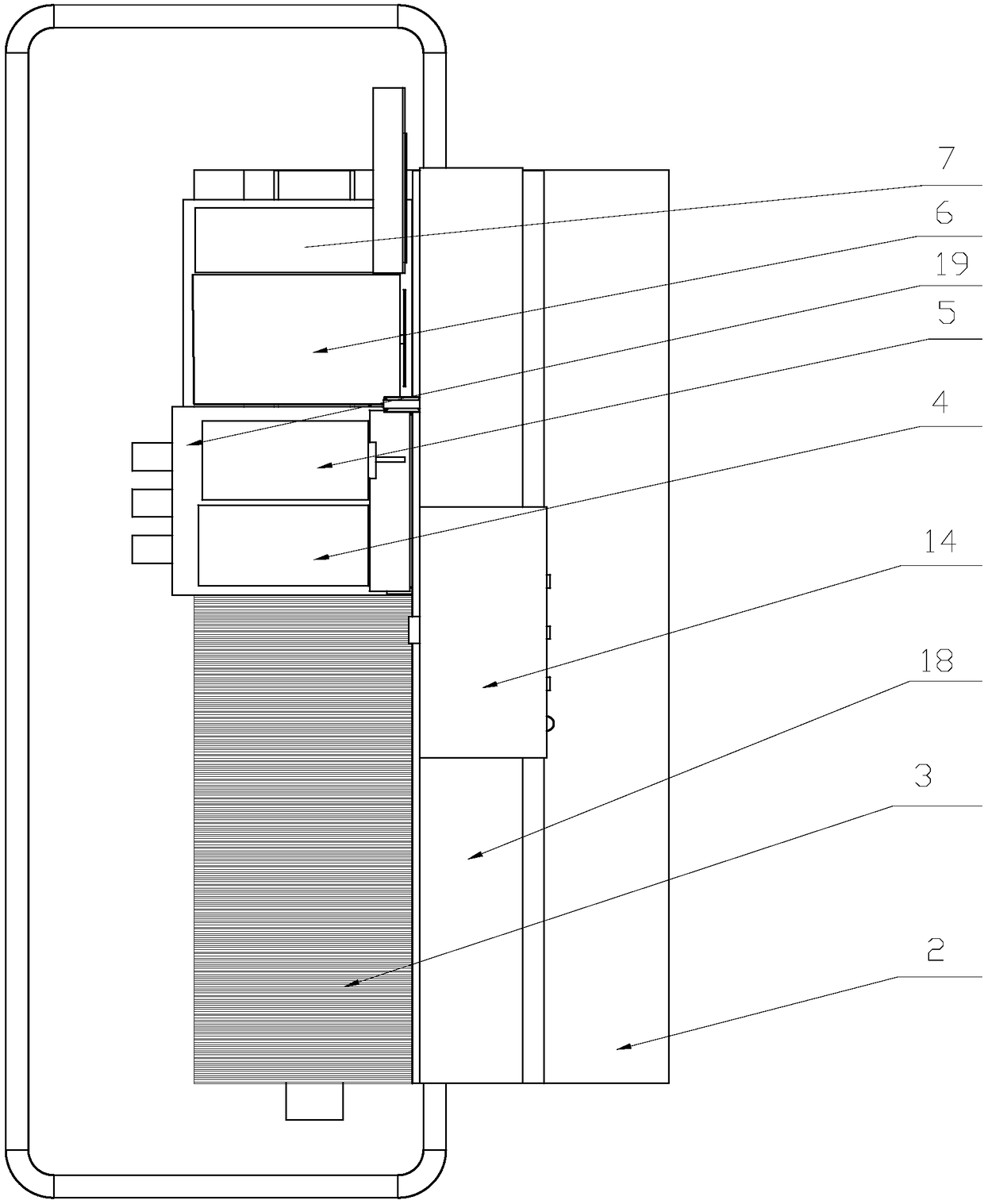

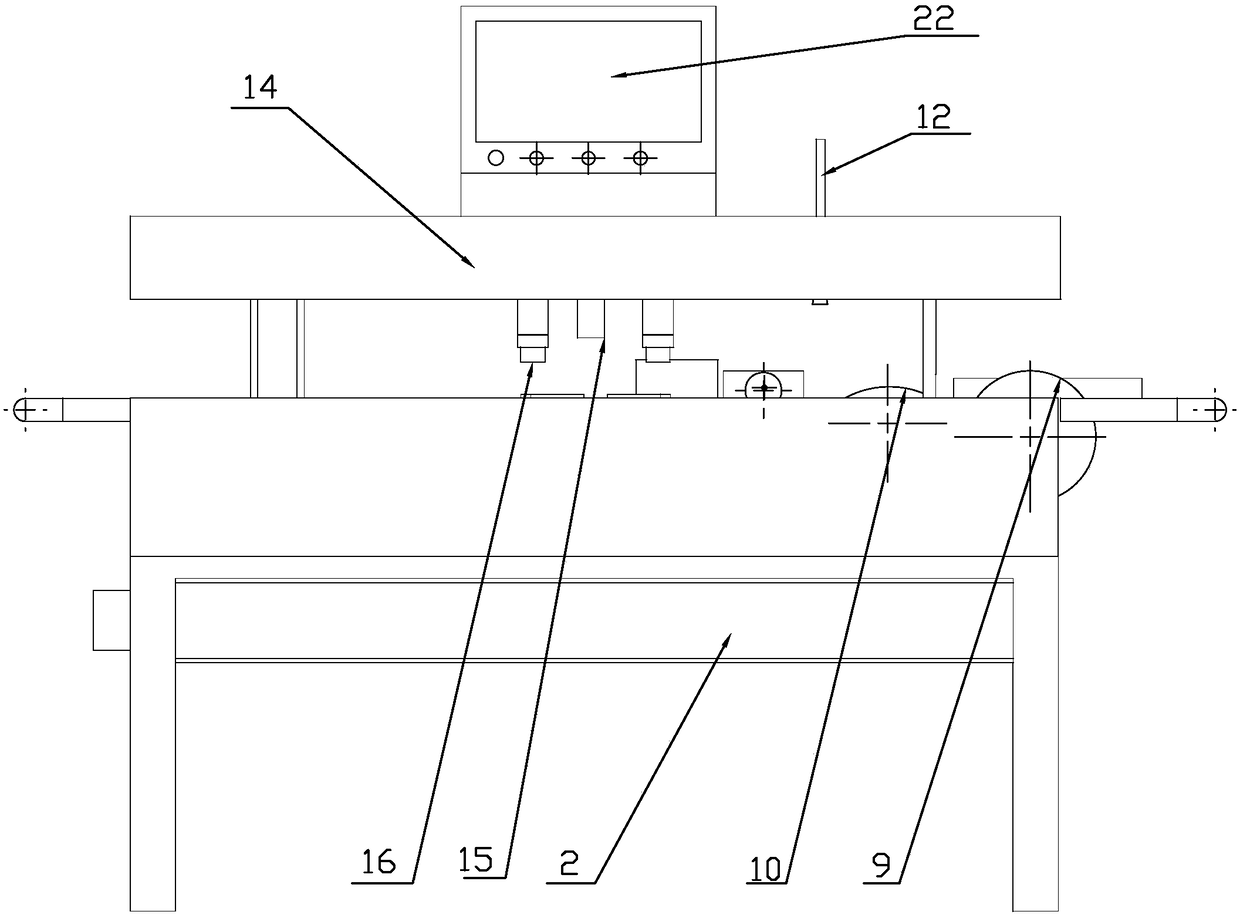

[0035] refer to Figure 1-Figure 4 , the efficient and precise cutting and drilling integrated machine includes a frame 2, a moving frame 19, an electric drill device, a cutting device and a control device 22 arranged on the moving frame 19; the moving frame 19 is driven by a stepping motor 1 and Move back and forth on the frame 2, thereby driving the electric drill device and the cutting device to move back and forth to drill and cut the planks. Described frame 2 is provided with fixed mount 14, compression cylinder 16, plank bearing platform 18 successively from top to bottom at the opposite end of mobile frame 19, wherein, compression cylinder 16 is fixed on fixed mount 18 bottom surfaces and will cut The wooden boards are compressed to prevent the boards from moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com