Long-life driving device for high-speed railway locomotive

A technology for high-speed railways and driving devices, which is applied to transmission devices driven by electric motors, railway vehicles, locomotives, etc., which can solve problems such as unfavorable driving device long-life operation, increased friction, and damage to pantographs, so as to prevent friction Increase, achieve long-life use, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

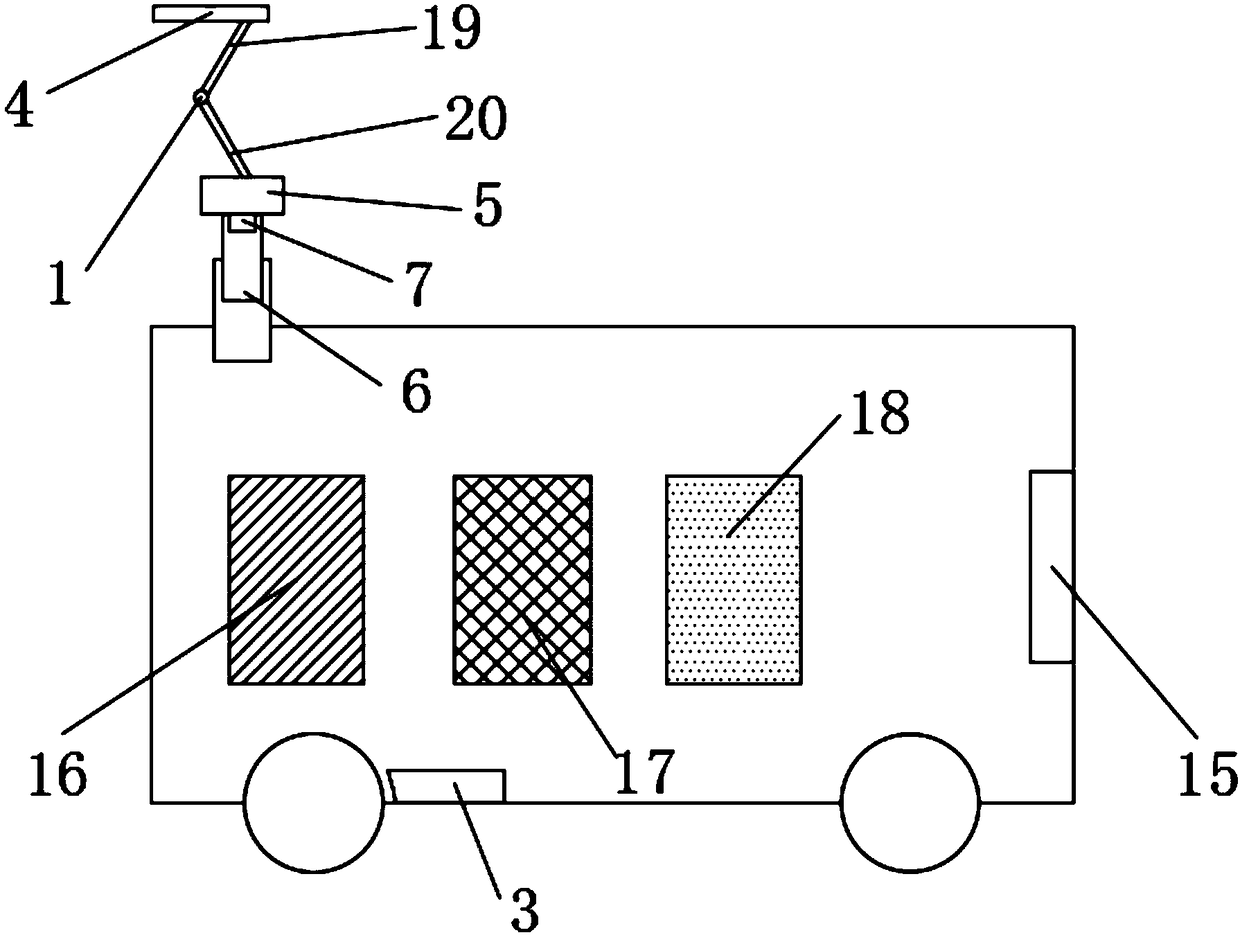

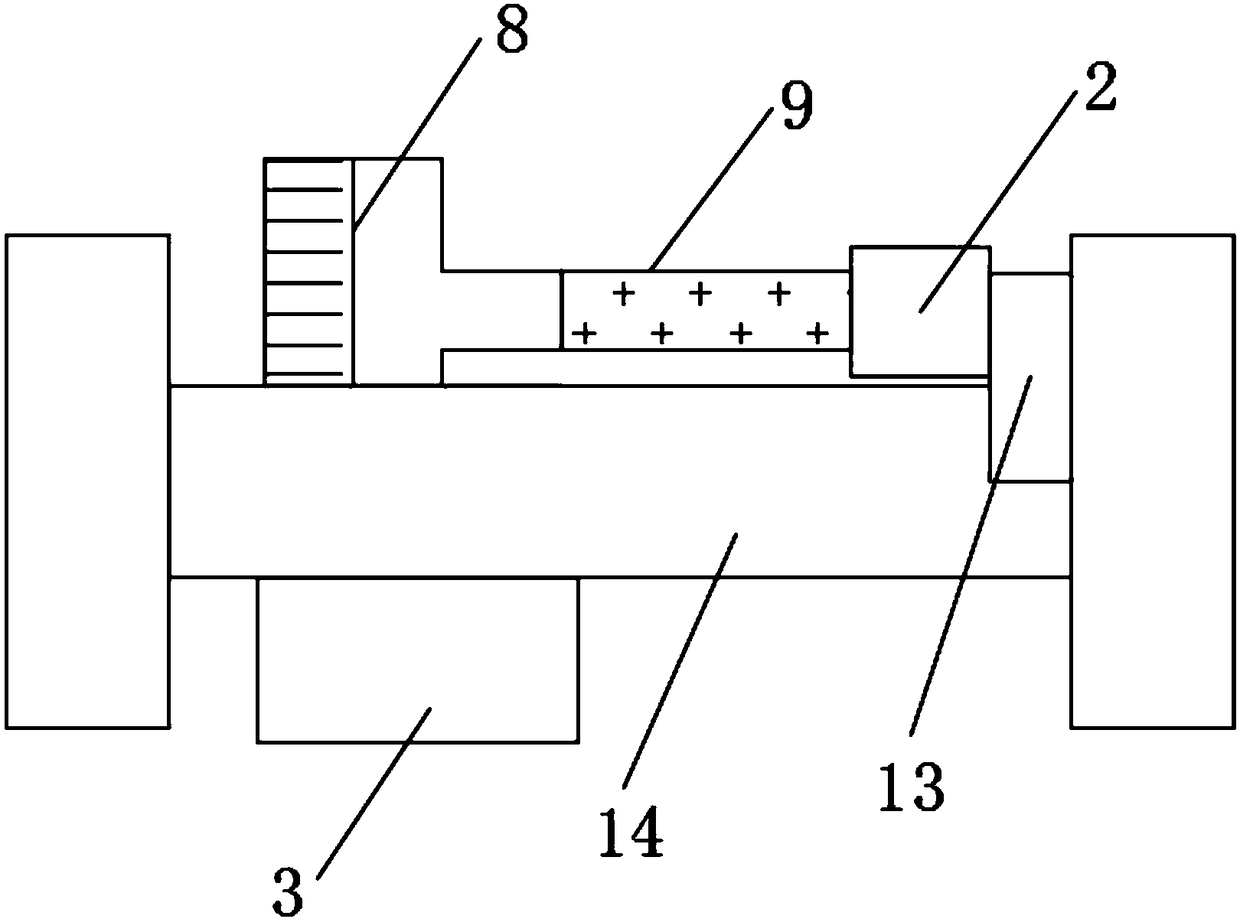

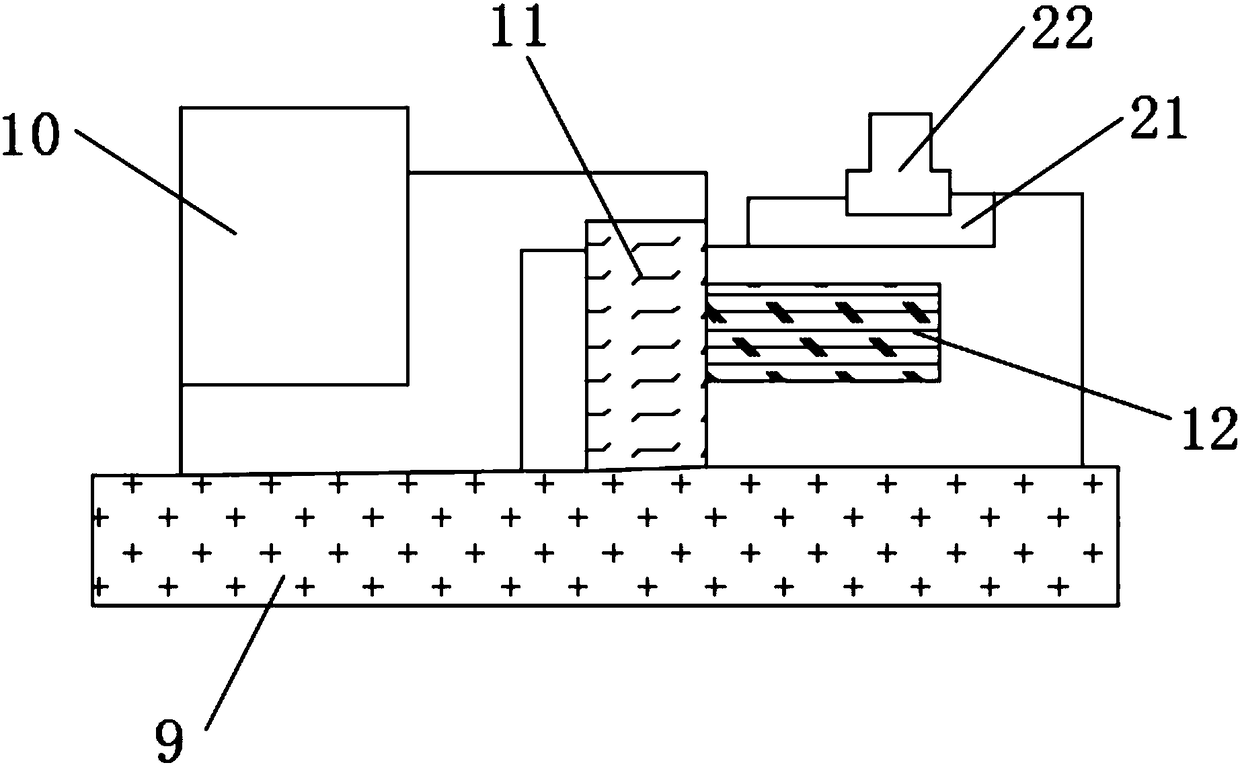

[0036] The present invention provides such Figure 1-3 The shown long-life drive device for a high-speed railway locomotive includes a pantograph 1, an electromagnetic clutch 2 and a speedometer 3, the upper part of the pantograph 1 is provided with a slide plate 4, and the lower part of the slide plate 4 is connected with A base 5, an electric telescopic rod 6 is installed on the bottom of the base 5, a pressure sensor 7 is installed inside the electric telescopic rod 6, and the pantograph 1 is electrically connected with a traction motor 8, and the traction motor 8 The driving end is connected with a driving gear 9, and the end side of the driving gear 9 is connected with an electromagnetic clutch 2 through a driven gear 10. The inside of the electromagnetic clutch 2 is provided with a friction plate 11, and the friction plate 11 is made of ferrous metal. The end side of the friction plate 11 is provided with a coil 12 for energizing to generate magnetic force. The driven ge...

Embodiment 2

[0048] A long-life driving device for a high-speed railway locomotive, comprising a pantograph 1, an electromagnetic clutch 2 and a speedometer 3, the upper part of the pantograph 1 is provided with a slide plate 4, and the lower part of the slide plate 4 is connected with a base 5, An electric telescopic rod 6 is installed on the lower part of the base 5, and a pressure sensor 7 is installed inside the electric telescopic rod 6. The pantograph 1 is electrically connected to a traction motor 8, and the driving end of the traction motor 8 is connected to There is a driving gear 9, the end side of the driving gear 9 is connected with an electromagnetic clutch 2 through a driven gear 10, the inside of the electromagnetic clutch 2 is provided with a friction plate 11, the friction plate 11 is made of ferrous metal, and the friction plate 11 is made of ferrous metal. A coil 12 is provided on the end side of the sheet 11 for generating magnetic force when energized. The driven gear 1...

Embodiment 3

[0061] A long-life driving device for a high-speed railway locomotive, comprising a pantograph 1, an electromagnetic clutch 2 and a speedometer 3, the upper part of the pantograph 1 is provided with a slide plate 4, and the lower part of the slide plate 4 is connected with a base 5, An electric telescopic rod 6 is installed on the lower part of the base 5, and a pressure sensor 7 is installed inside the electric telescopic rod 6. The pantograph 1 is electrically connected to a traction motor 8, and the driving end of the traction motor 8 is connected to There is a driving gear 9, the end side of the driving gear 9 is connected with an electromagnetic clutch 2 through a driven gear 10, the inside of the electromagnetic clutch 2 is provided with a friction plate 11, the friction plate 11 is made of ferrous metal, and the friction plate 11 is made of ferrous metal. A coil 12 is provided on the end side of the sheet 11 for generating magnetic force when energized. The driven gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com