A kind of preparation method of copper-modified violet tungsten photocatalyst

A technology of photocatalyst and purple tungsten, which is applied in the field of preparation of copper-modified purple tungsten photocatalyst, can solve the problems of particle size and distribution, uneven pore structure, insufficient mixing uniformity, high catalyst cost, etc., and achieve excellent catalytic effect, Low cost and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

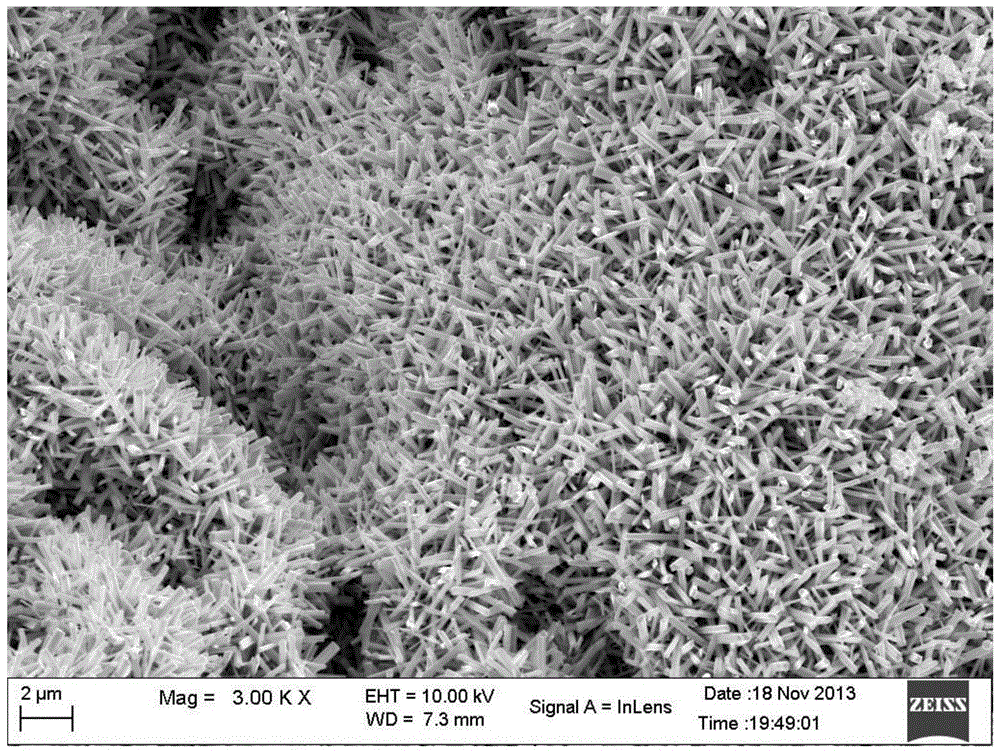

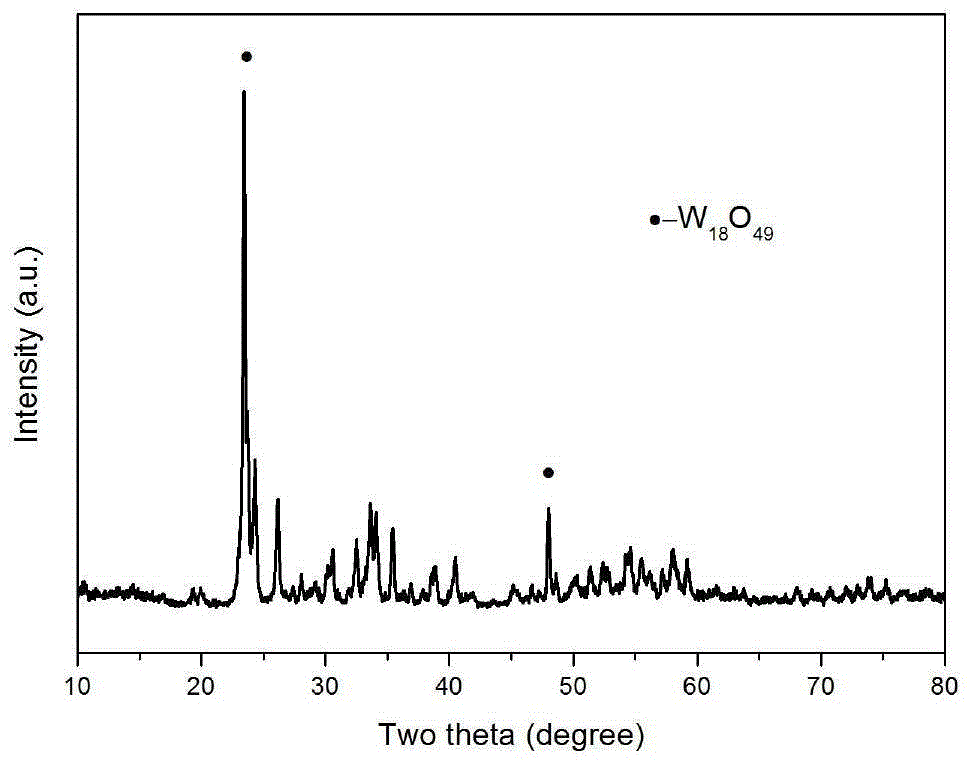

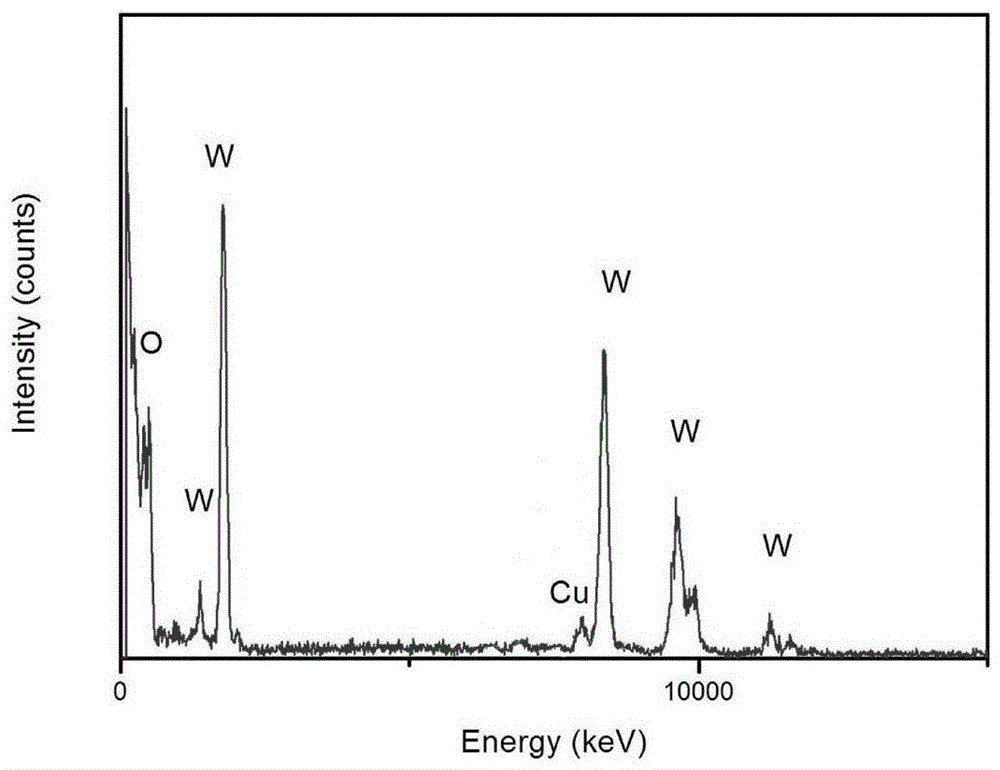

[0021] Weigh copper nitrate (Cu(NO 3 ) 2 )0.01mol, ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 )0.24mol, urea (CO(NH 2 ) 2 )0.1mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until it is completely dissolved, heat at a constant temperature of 200°C, and after the solution is evaporated to dryness, a violent redox reaction occurs within tens of seconds to form copper-doped violet tungsten powder. The obtained powder is in the shape of nano needles with a diameter of 30-150 nm and a length of 1-3 μm. It takes 40 minutes for the catalyst with a concentration of 1 g / L to completely degrade 20 ppm of organic pollutants (methylene blue).

Embodiment 2

[0023] Weigh copper nitrate (Cu(NO 3 ) 2 )0.01mol, ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 )0.24mol, urea (CO(NH 2 ) 2 )0.15mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until it is completely dissolved, heat at a constant temperature of 200°C, and after the solution is evaporated to dryness, a violent redox reaction occurs within tens of seconds to form copper-doped violet tungsten powder. The obtained powder is in the shape of nano needles with a diameter of 50-150 nm and a length of 1-3 μm. It takes 35 minutes for the catalyst with a concentration of 1 g / L to completely degrade 20 ppm of organic pollutants (methylene blue).

Embodiment 3

[0025] Weigh copper nitrate (Cu(NO 3 ) 2 )0.01mol, ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 )0.36mol, urea (CO(NH 2 ) 2 )0.1mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until completely dissolved, then heat at a constant temperature of 200°C, and after the solution is evaporated to dryness, a violent redox reaction occurs within tens of seconds to form copper-doped violet tungsten powder. The obtained powder is in the shape of nano needles with a diameter of 60-150 nm and a length of 1-2 μm. It takes 50 minutes for the catalyst with a concentration of 1 g / L to completely degrade 20 ppm of organic pollutants (methylene blue).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com