Unfolding locking mechanism based on torsion spring

A technology of torsion spring and locking mechanism, applied in the direction of motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problems of heavy weight, low reliability, large size, etc., achieve light weight, improve stability and Reliability, small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

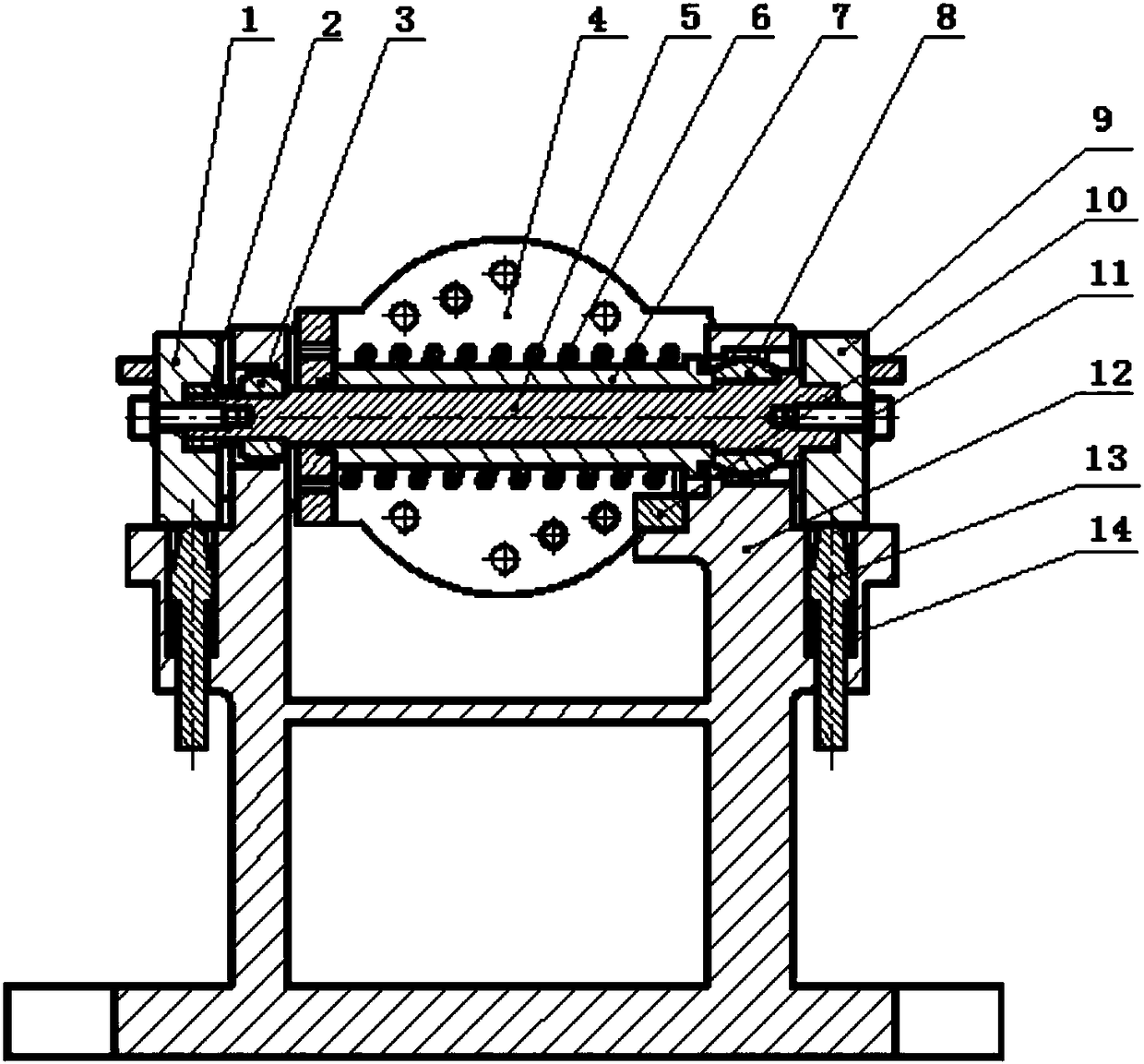

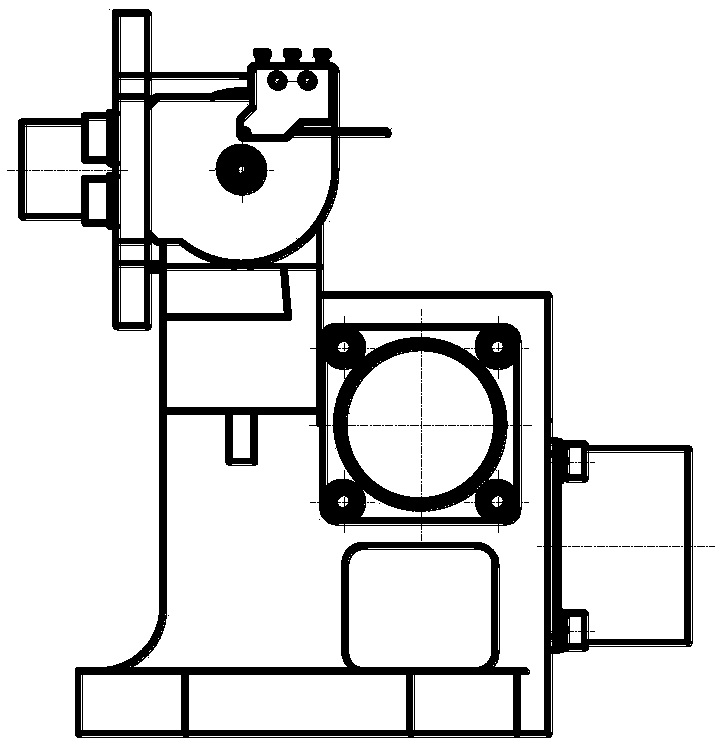

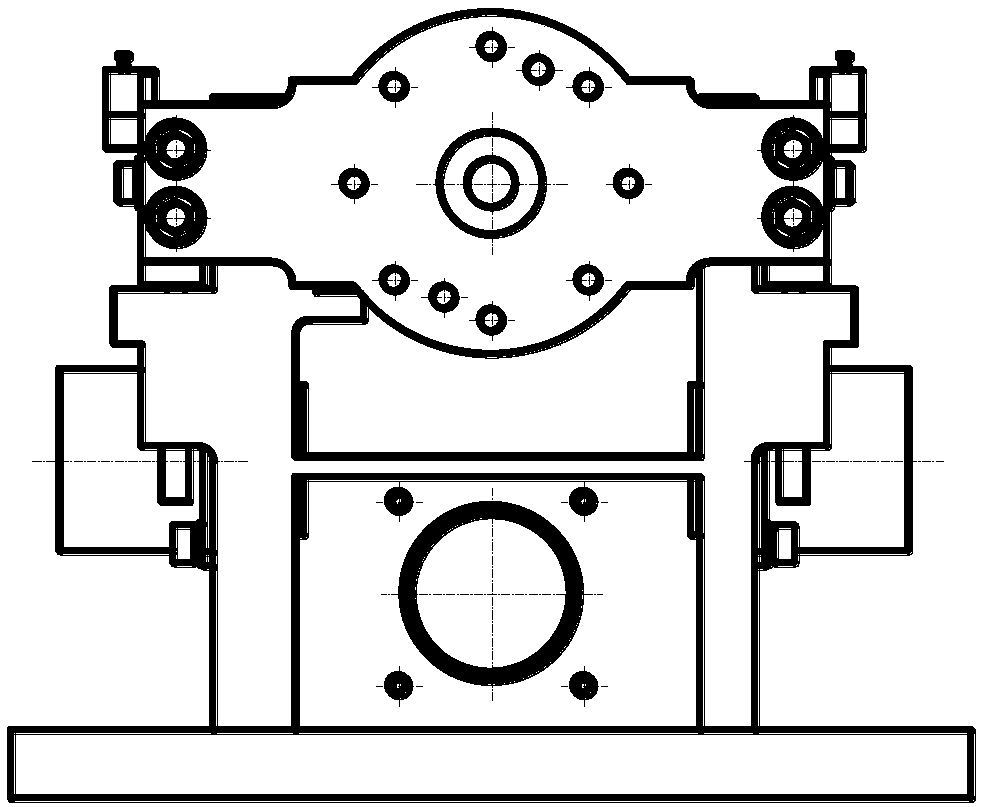

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0032] The deployment locking mechanism based on the torsion spring provided by the present invention includes a frame 12, a rotating shaft 5, a torsion spring 6, a connecting piece 4, two locking rods 13, a slideway L1, and a slideway R9.

[0033] Such as image 3 , Figure 5 As shown, the main body of the connector 4 is a flange, and the two sides of the flange are symmetrically provided with protruding rods, and the flange is threadedly connected with the external expanded mechanism. Such as Figure 6 As shown, a boss is provided along the normal direction of the flange, and the boss is provided with a through hole matched with the rotating shaft 5, and boss holes matched with the straight legs of the torsion spring 6 are evenly arranged along the outer circumference of the through hole. There are 16 boss holes in total. The connecting lines of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com