Public platform satellite chemical propulsion subsystem modular layout method

A technology of chemical propulsion and layout method, which is applied to the propulsion system devices of space navigation aircraft, space navigation equipment, space navigation aircraft, etc., and can solve problems such as inability to weld, difficulty in troubleshooting, and inability to accurately determine the location of problems in a timely manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

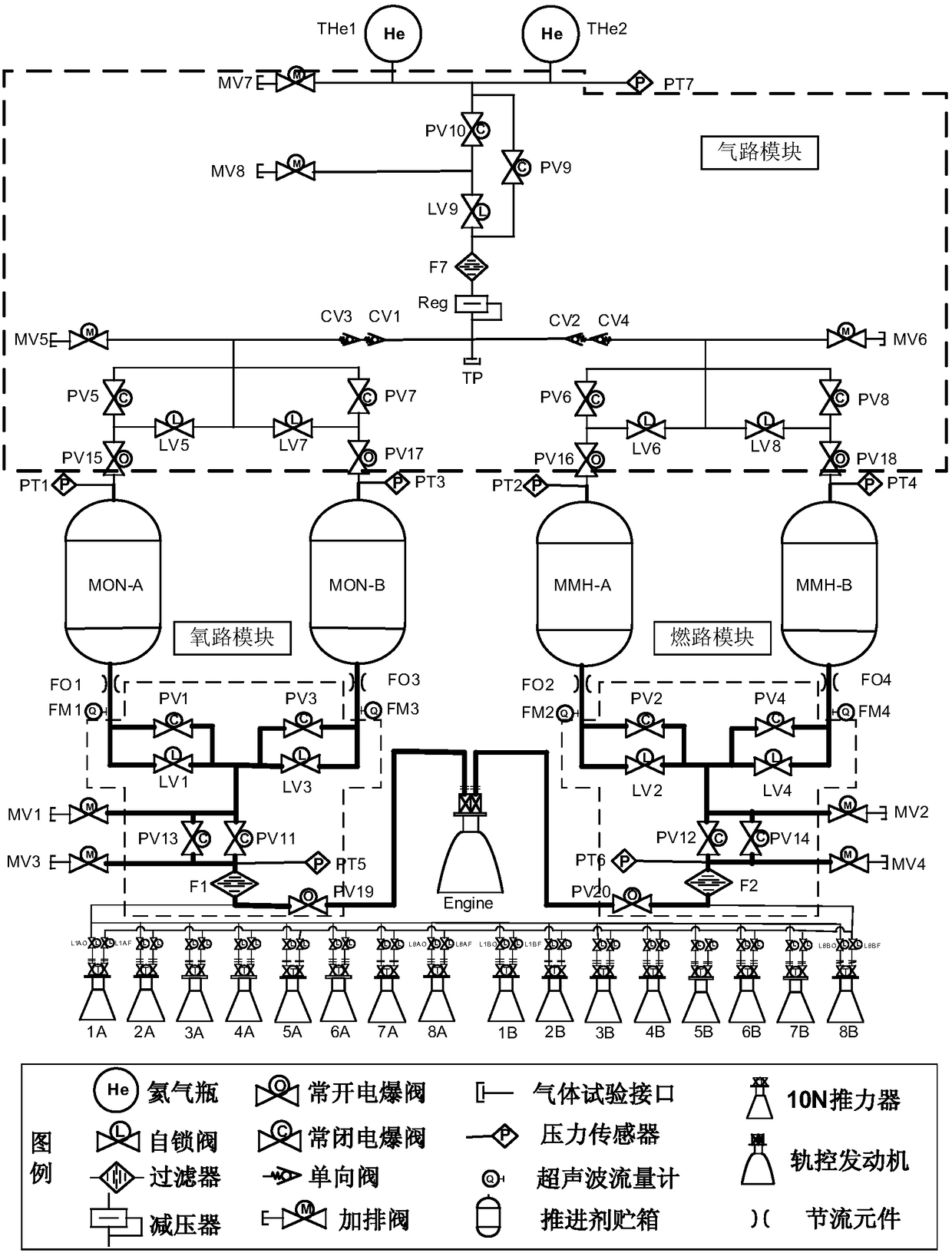

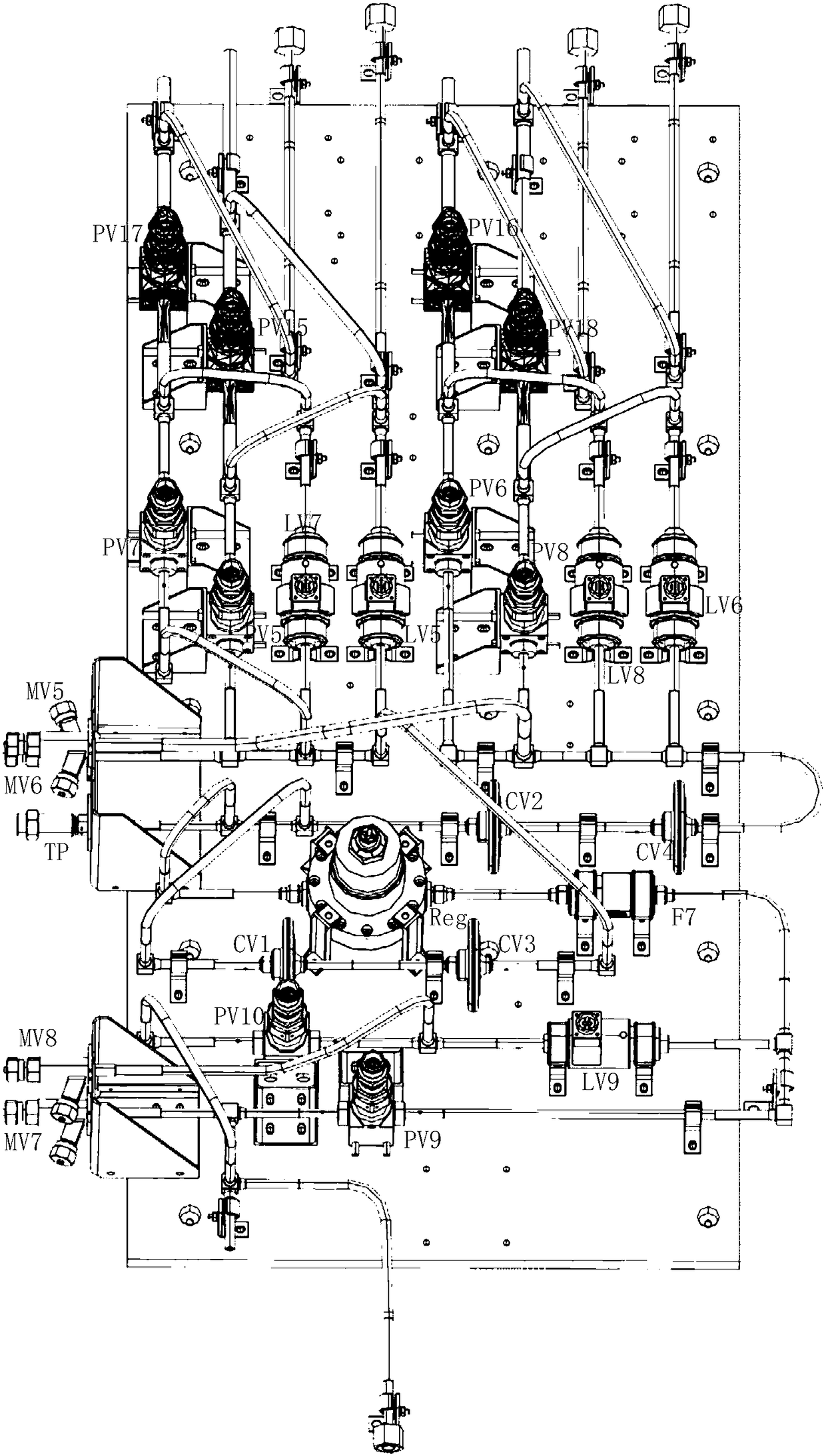

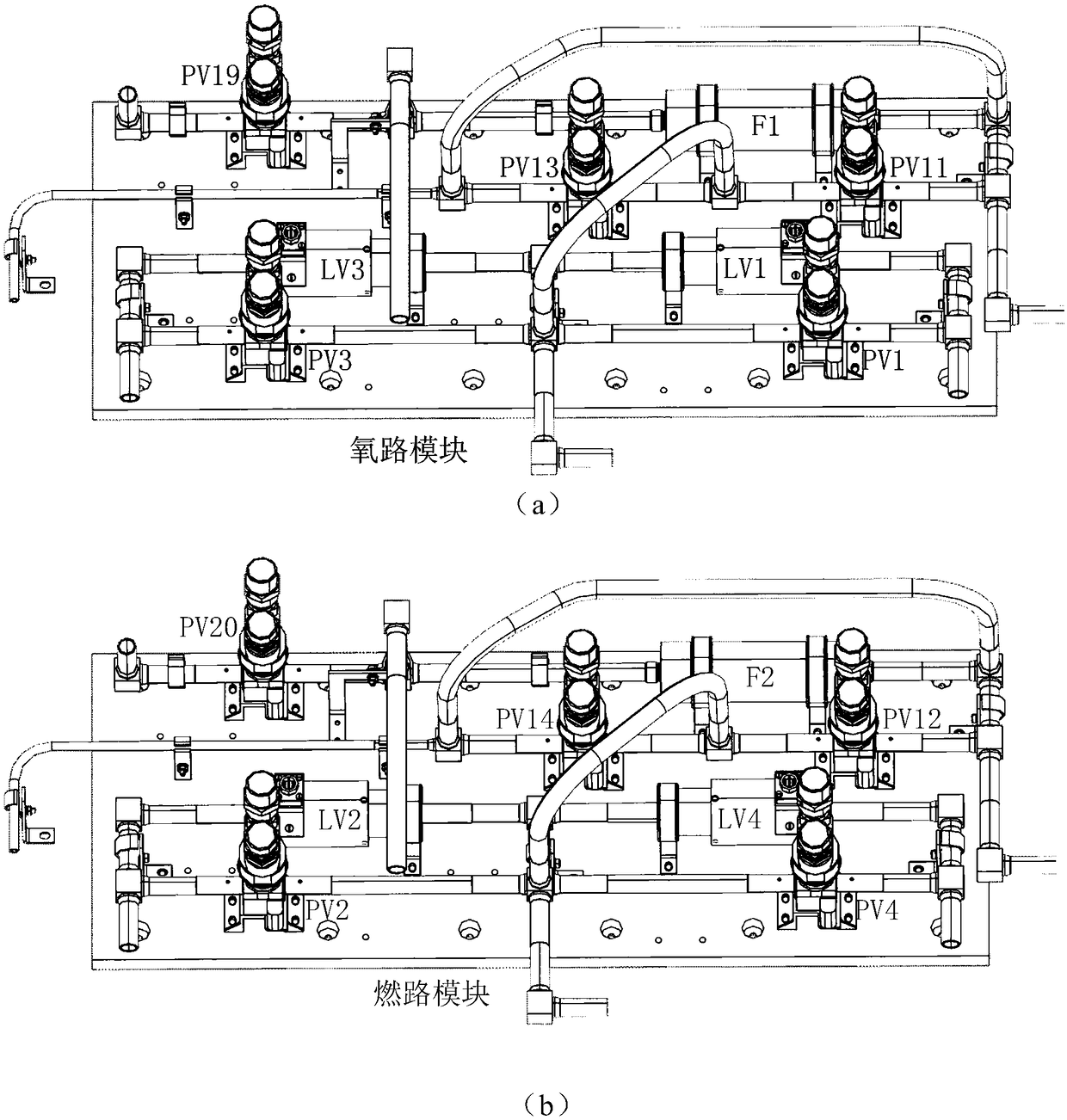

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0054] A method for modular layout of the chemical propulsion subsystem of a public platform satellite according to the present invention provides a modular layout method for the chemical propulsion subsystem of a public platform satellite based on the structure of the DFH-5 platform and the principle of the chemical propulsion subsystem. The layout of the chemical propulsion system of the satellite platform is not divided into valve body modules according to the propulsion principle. The valve bodies with different functions are arranged together, which takes up too much space on the deck; A large number of equipment on the satellite can only be welded again after dismantling, even in the later stage of satellite manufacturing; the valve body with different functions is arranged together, and when a problem occurs in the test, it is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com