Continuous cyaniding device and technology thereof

A technology of process and process water, which is applied in the field of synthesis process, can solve the problems of relatively high technical level requirements for operators and large investment, and achieve the effects of reducing reaction time, improving work efficiency and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

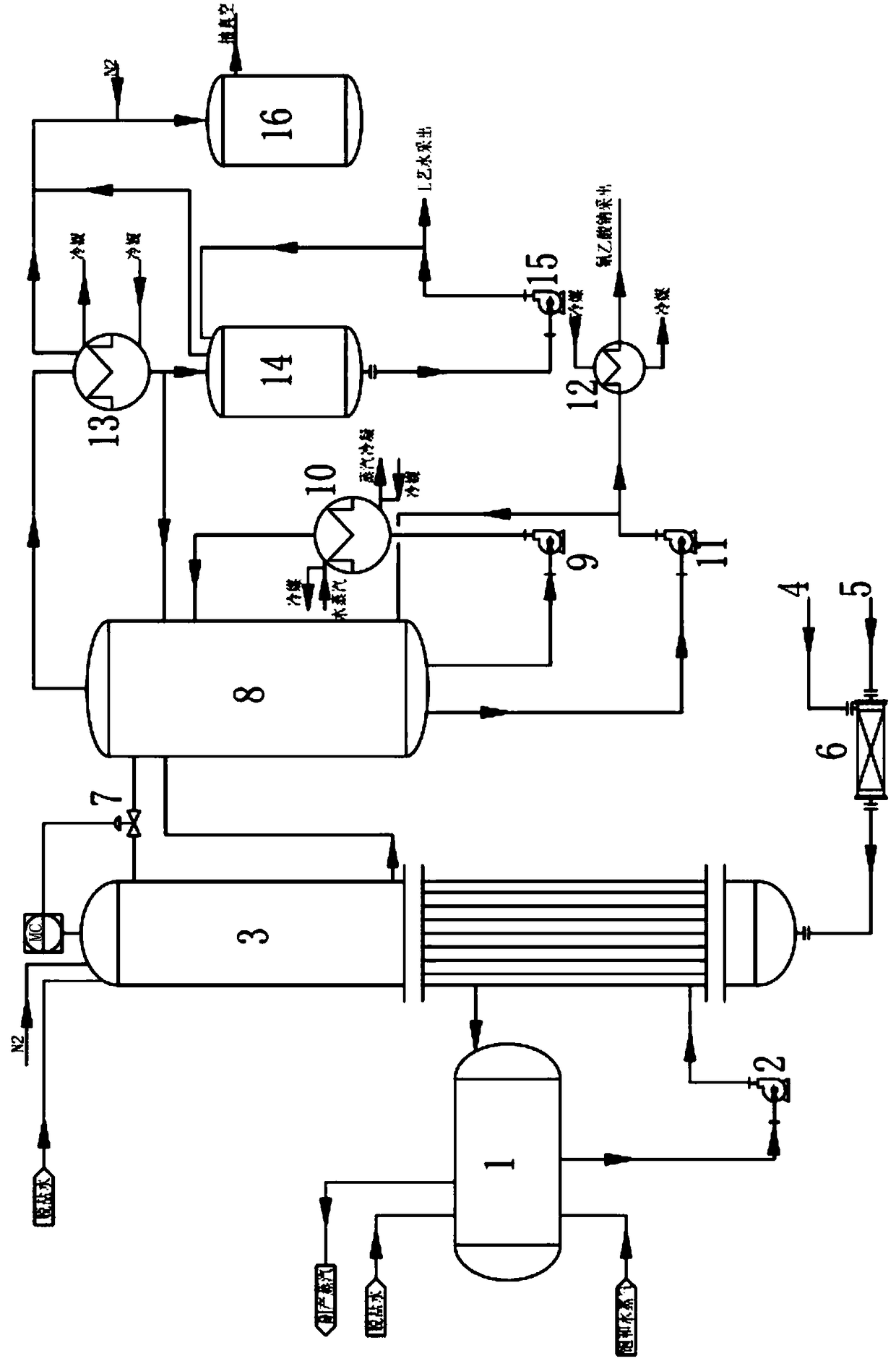

[0031] like figure 1 Shown, a kind of continuous cyanation device, described device comprises saturated water tank 1, cyanation reactor 3, cyanation stabilizer 8, steam condenser 13, process water receiving tank 14, cyanation vacuum buffer tank 16; The saturated water tank 1 is connected to the cyanation reactor 3 through the saturated water circulation pump 2; the cyanation reactor 3 is connected to the cyanation stabilizer 8, and the bottom of the cyanation reactor 3 is connected to a cyanation feed mixer group 6; the top of the cyanide stabilizer 8 is connected to the process water receiving tank 14 through a steam condenser 13, and the bottom of the cyanide stabilizer 8 is connected to a circulation heater 10 through a stabilizer circulation pump 9, and the circulation heater 10 is connected to To the middle and upper part of the cyanide stabilizer 8; the cyanide vacuum buffer tank 16 is respectively connected to the steam condenser 13 and the process water receiving tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com