Buffering and damping device with adjustable rigidity and mounting method of buffering and damping device

A technology of shock absorbing device and rigidity, which is applied in the direction of shockproof, construction, artificial island, etc. It can solve the problems of rubber deformation hugging the guide shaft body, affecting the shock absorption effect, and non-adjustable stiffness, so as to achieve the integrity of the protection structure and the shock absorption effect Good, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

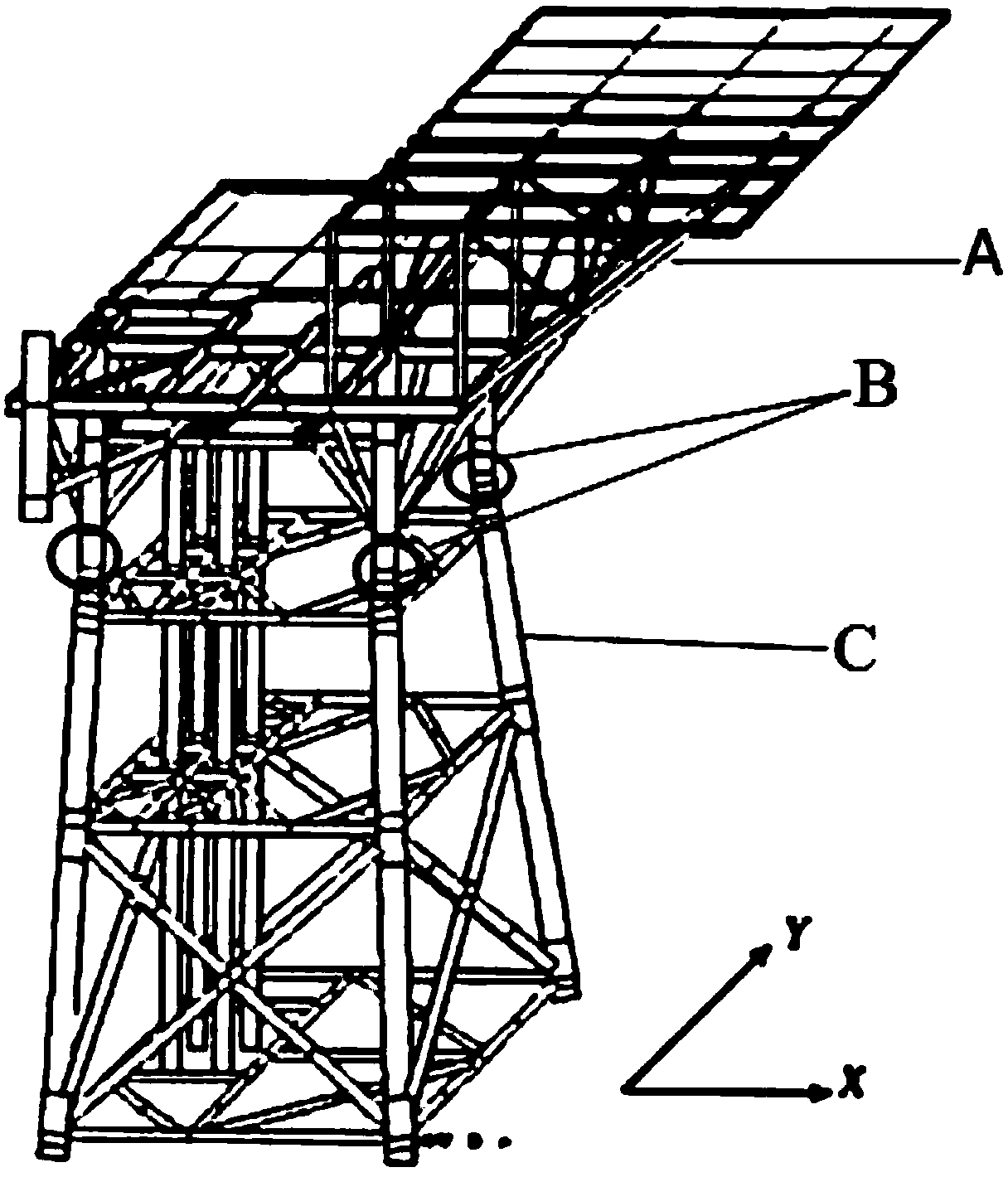

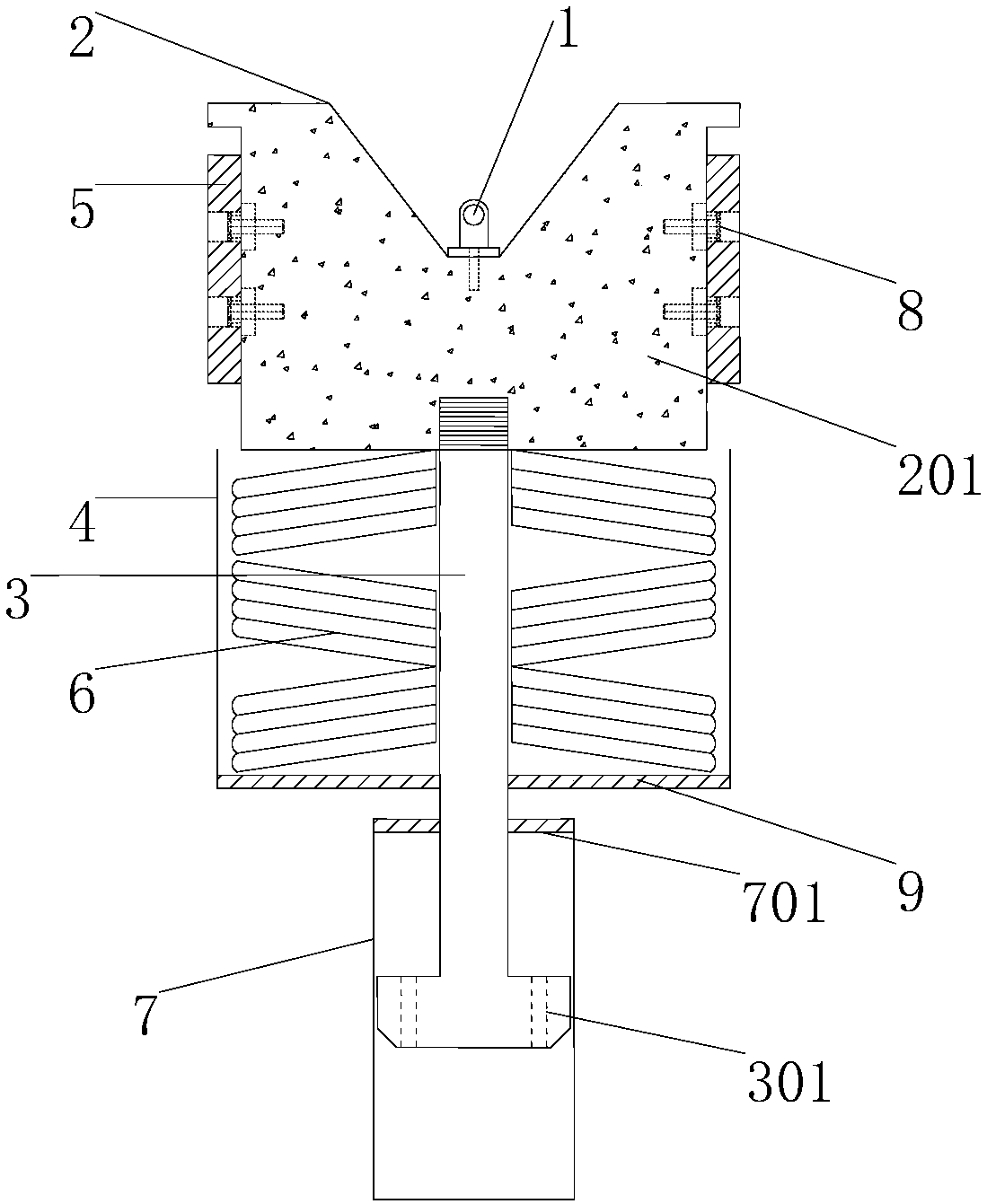

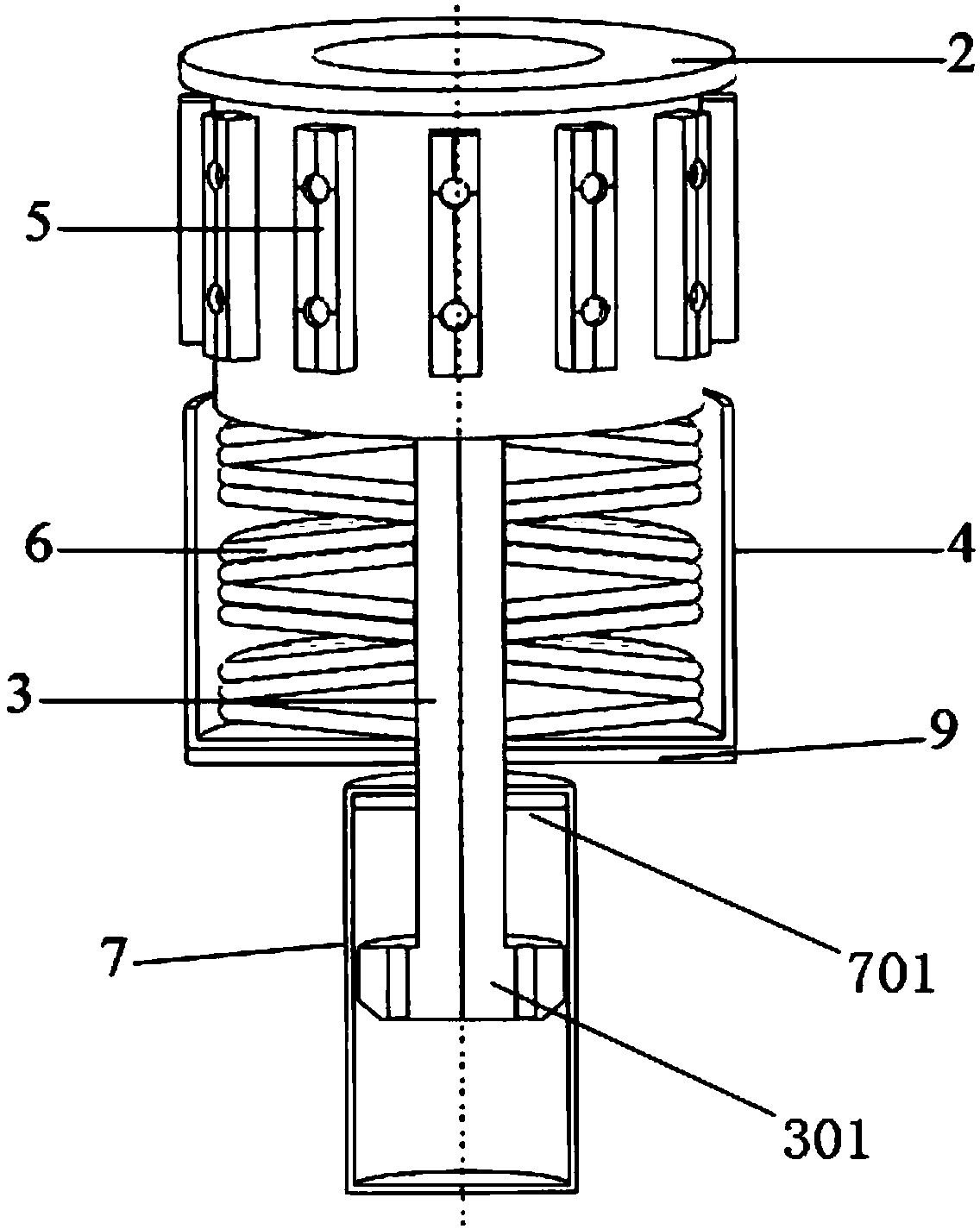

[0063] Such as figure 1 , Figure 13 , Figure 14 or Figure 15 As shown, select the traditional jacket offshore platform form, figure 1 Among them, A is the upper block, B is the installation position of the present invention, and C is the jacket. The buffer and damping device of this embodiment includes a lateral shock-absorbing elastic body 5 and a conical receiver 2 coaxially arranged, a rigid shaft The body 3 and the vertical damping module, 16 transverse damping elastic bodies 5 are fixed on the side of the conical receiver 2 at intervals by bolts 8 for a week, the inside of the conical receiver 2 is filled with concrete 201, the upper part of the conical receiver 2 There is a conical cup mouth 202, and a detachable hanging plate 1 is pre-installed in the conical cup mouth 202. The conical receiver 2 is connected with the vertical shock-absorbing module through the rigid shaft body 3, and the vertical shock-absorbing module is set on the conical Below the receiver 2;...

Embodiment 2

[0069] Different from Example 1, the offshore platform in Example 2 is a pipe-in-pipe concrete-filled steel pipe offshore platform with a relatively novel form, and the installation conditions are relatively harsh, such as Figure 16 , Figure 17 , Figure 18 or Figure 19 As shown, the difference between it and the traditional offshore platform is that the outer diameter of the upper block conduit 10 is larger than the outer diameter of the pile legs, and the pile legs are in the form of tube-in-pipe concrete-filled steel pipe pile legs 18, and the device of the present invention is installed near the top of the pile legs. The hollow area used. In order to solve the problem of connecting the upper and lower different sections, the outer steel pipe of the pile leg is welded with a stiffener 12 and a pressure bearing plate 13 one week.

[0070] The device of the present invention is hoisted into the pipe-in-pipe concrete-filled steel pipe pile legs 18, the shell 4 just sits ...

Embodiment 3

[0076] In the field of prefabricated buildings, the mass of the upper block is generally small, and the installation environment is more stable than that of the offshore platform, so the impact force generated by collision and installation is relatively small. The difference between this embodiment and Embodiment 1 is that the viscous damper 7 is disassembled and used, which is especially suitable for the assembly of building structures with relatively small superstructure mass. Such as Figure 20 The upper assembly unit D includes the frame beam and the steel pipe column top column 15, the lower assembly unit E includes the frame beam and the steel pipe column bottom column 16, and the assembly node B of the upper assembly unit D and the lower assembly unit E is installed with a shock absorbing device. Such as Figure 21 , Figure 22 and Figure 23 As shown, the limit support III173 of the central opening is pre-installed on the inner side of the steel pipe column bottom c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com