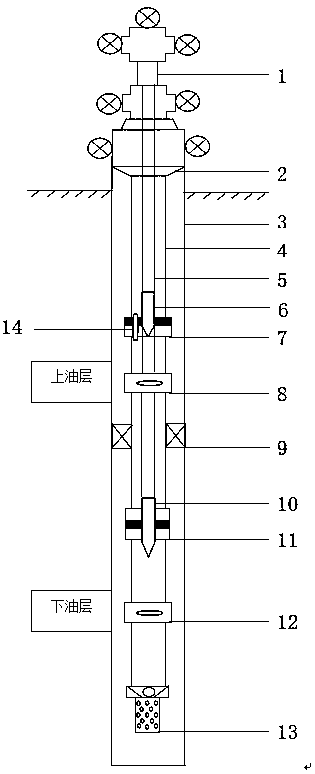

Secondary hanging double-pipe separate injection technology pipe column

A technology for process pipe string and outer pipe string, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc. The effect of breaking through the maximum well depth limit, expanding the scope of application and improving the practical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

[0018] as attached figure 1 As shown, the secondary suspension double-pipe dispensing process string includes the outer pipe 4 and the inner pipe 5. The outer pipe 4 can be regarded as a whole, and other accessories are connected to it in turn, or it can be divided into multiple outer pipes, such as the first An outer tube, a second outer tube, a third outer tube, a fourth outer tube, and a fifth outer tube, and then the outer tubes are connected to other fittings between two pairs or their ends. The inner tube 5 can also be compared in this way. The inner pipe is arranged coaxially inside the outer pipe, the central cavity of the inner pipe is used as an inner water injection channel connected to the lower oil layer, and the annular space formed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com