Special furnace end for alcohol power novel environment-friendly fuel cooking utensil

A burner and power technology, applied in the field of cookers, can solve problems such as flame slack, burner effusion, lack of flame guidance, etc., and achieve the effects of reducing air intake loss, obvious flame guidance, and increasing the shrinkage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

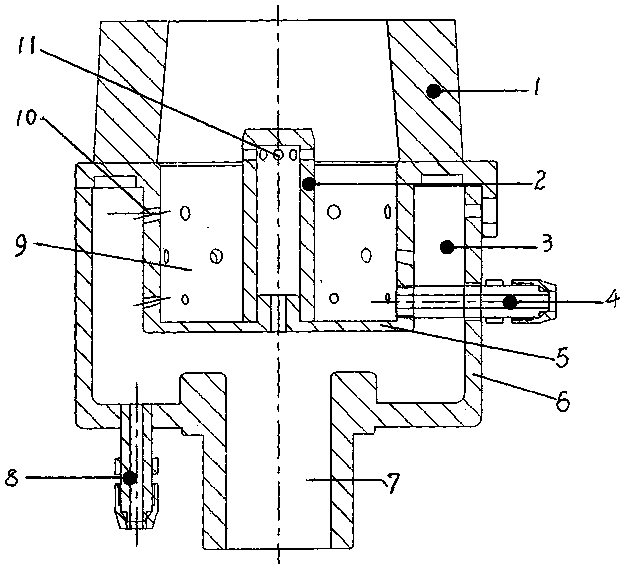

[0009] As shown in the figure, the present invention is mainly composed of a furnace head 3, the furnace head 3 is a hollow structure, composed of an inner layer 5 and an outer layer 6 of the furnace head 3, the bottom of the furnace head 3 is provided with an air inlet 7, and the furnace head In the middle of 3, there is an atomization chamber 9 inside the inner layer 5 of the burner head. On the inner layer 5 of the burner head, there are a number of vent holes 10 inclined upward at 12° to promote the concentration of the flame. In the middle of the burner head 3, there is a small core The upper part of the small core 2 is also provided with a vent 11, and the middle part of the burner 3 is provided with a horizontally designed oil inlet nozzle 4, and the oil inlet nozzle 4 directly extends into the atomization chamber 9 in the middle of the burner 3. The bottom of the head outer layer 6 is also provided with an oil spill nozzle 8 to prevent liquid accumulation in the burner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com