Potato leaf shredder machine with zigzag cutting blade

A cutting blade and sawtooth-type technology, which is applied in the field of new sawtooth-type potato seedling killing machine, can solve the problems of easy entanglement of stems and seedlings, uneven crushing length, potato rate and clay on the machine, and reduce forward resistance , Improving the efficiency of killing seedlings, and the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

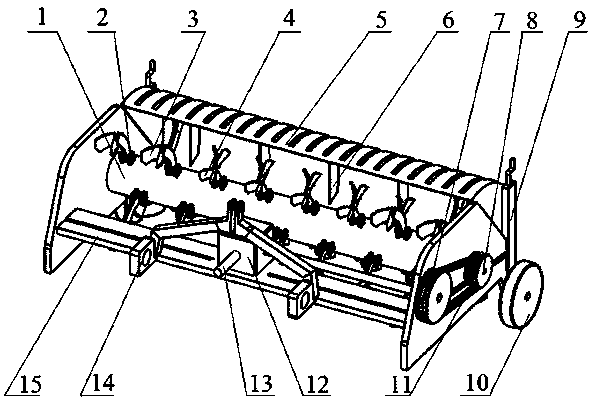

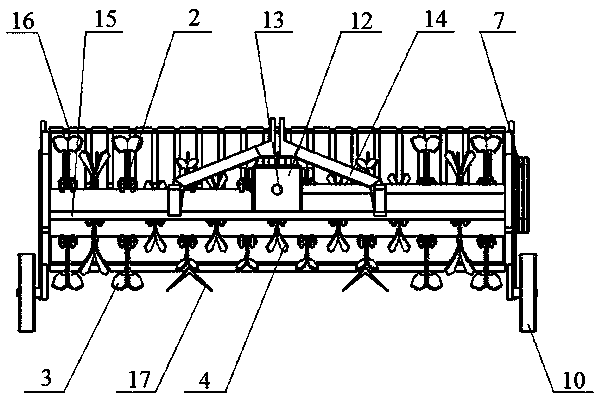

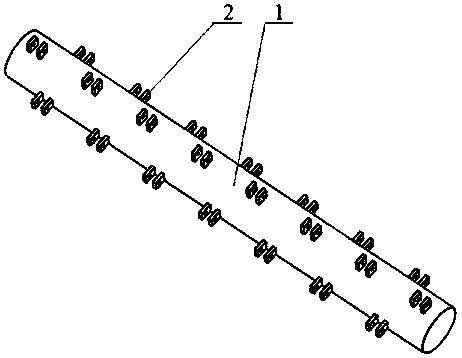

[0020] As shown in the figure, a sawtooth cutting blade potato seedling killing machine includes a frame 15. The frame 15 is connected with a tractor using a three-point suspension traction frame. The tractor provides traction and operating power, and the lower suspension points are welded to the frame. 15 corners of the support plate, the upper suspension point is welded with angle steel. The ground wheel 10 is installed on the rear bottom of the frame 15 through a height adjustment mechanism 9, and the height adjustment mechanism 9 is used to adjust the height of the ground wheel 10. The driven pulley 8 is installed on one end of the knife roller 1, and one end stretches out of the frame 15 to connect the driven pulley 8 through a flat key. The two ends of the knife roller 1 are horizontally installed on the frame 15 through rolling bearings, and the bevel gear reducer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com