Polyurethane anti-blocking self-cleaning sieve plate manufacturing method

A production method, polyurethane technology, applied in chemical instruments and methods, sieving, solid separation, etc., can solve the problems of reduced screen penetration rate of sieve plate, blockage of sieve plate sieve gap, increased loss of sieve plate, etc., and achieve the improvement of processing capacity , save the time of blockage, and save the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0033] A method for making a polyurethane anti-blocking self-cleaning sieve plate, comprising the following steps:

[0034] A. Make screen 1;

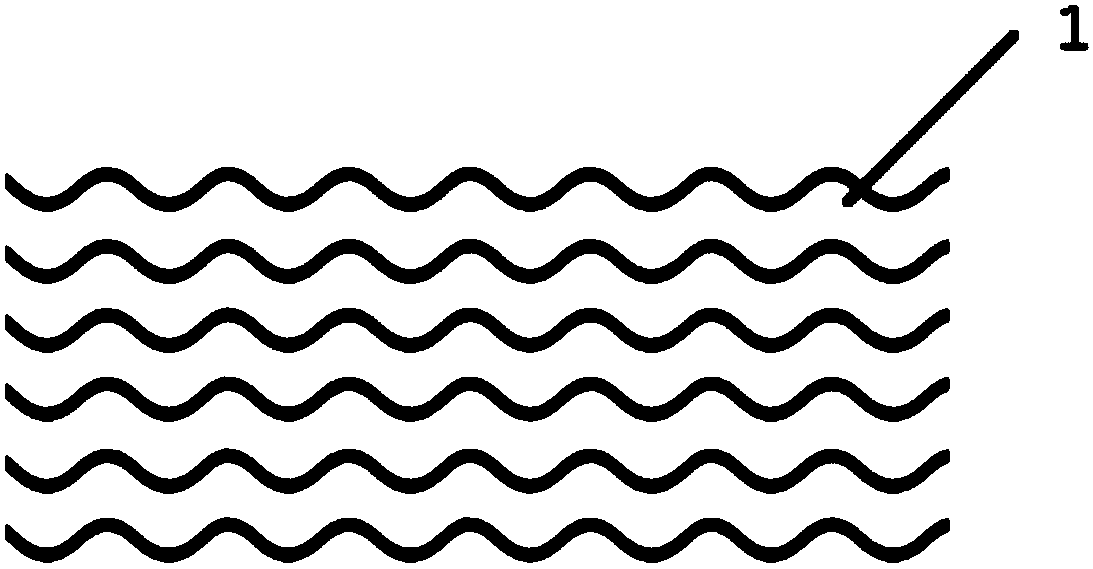

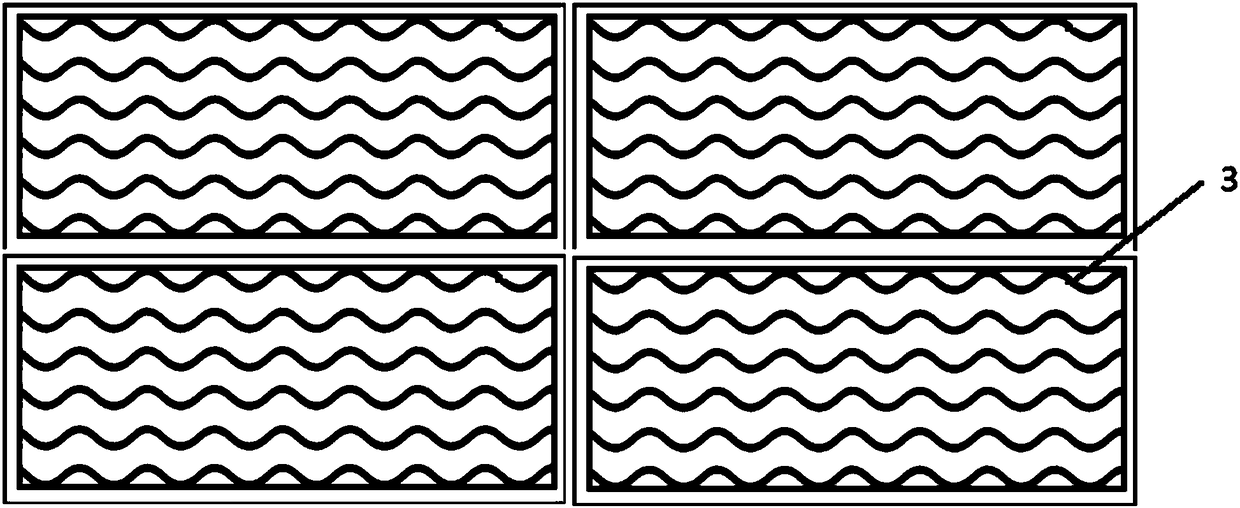

[0035] See attached figure 1 , tie a plurality of special spring steel wires into waves and arrange them in parallel. The troughs of adjacent stainless steel wires face troughs, and the peaks face each other, forming a sieve gap; since the cross section of special spring steel wires is circular, see the attached Figure 4 , in this example, the section between the spring steel and the adjacent spring steel wire forms a funnel shape with a wide top and a narrow bottom. When the sieve machine vibrates, each sieve wire vibrates independently, and the sieved material will not be stuck or sticky, achieving the effect of self-cleaning;

[0036] B. Making casting molds;

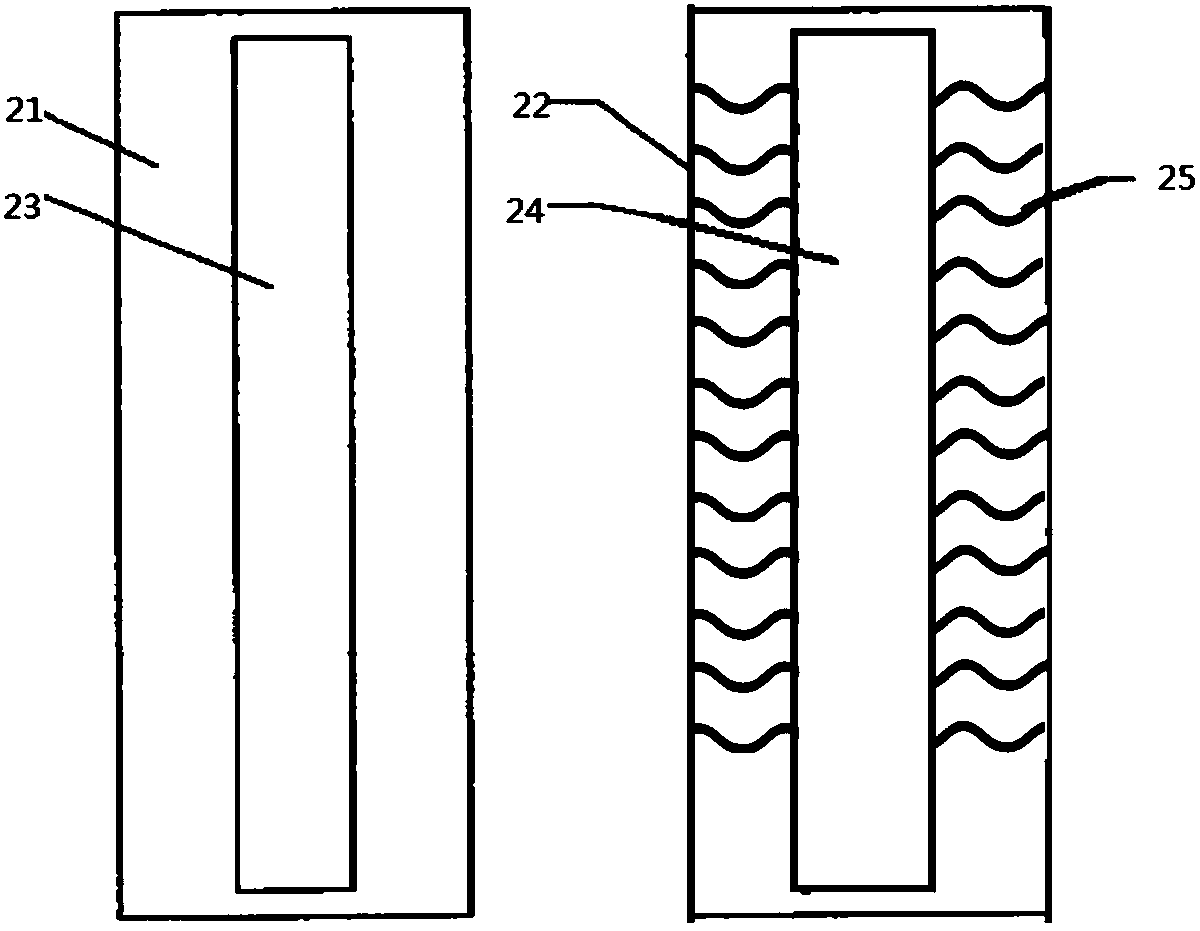

[0037] See attached figure 2 The pouring mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com