Compressor cylinder block machining fixture

A compressor cylinder block and fixture technology, which is used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the accuracy and quality of inclined holes cannot be unified, the quality of automobile air-conditioning compressors decreases, and the position of inclined holes exits. Inconsistency and other problems, to achieve the effect of improving repeated positioning accuracy, increasing applicability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

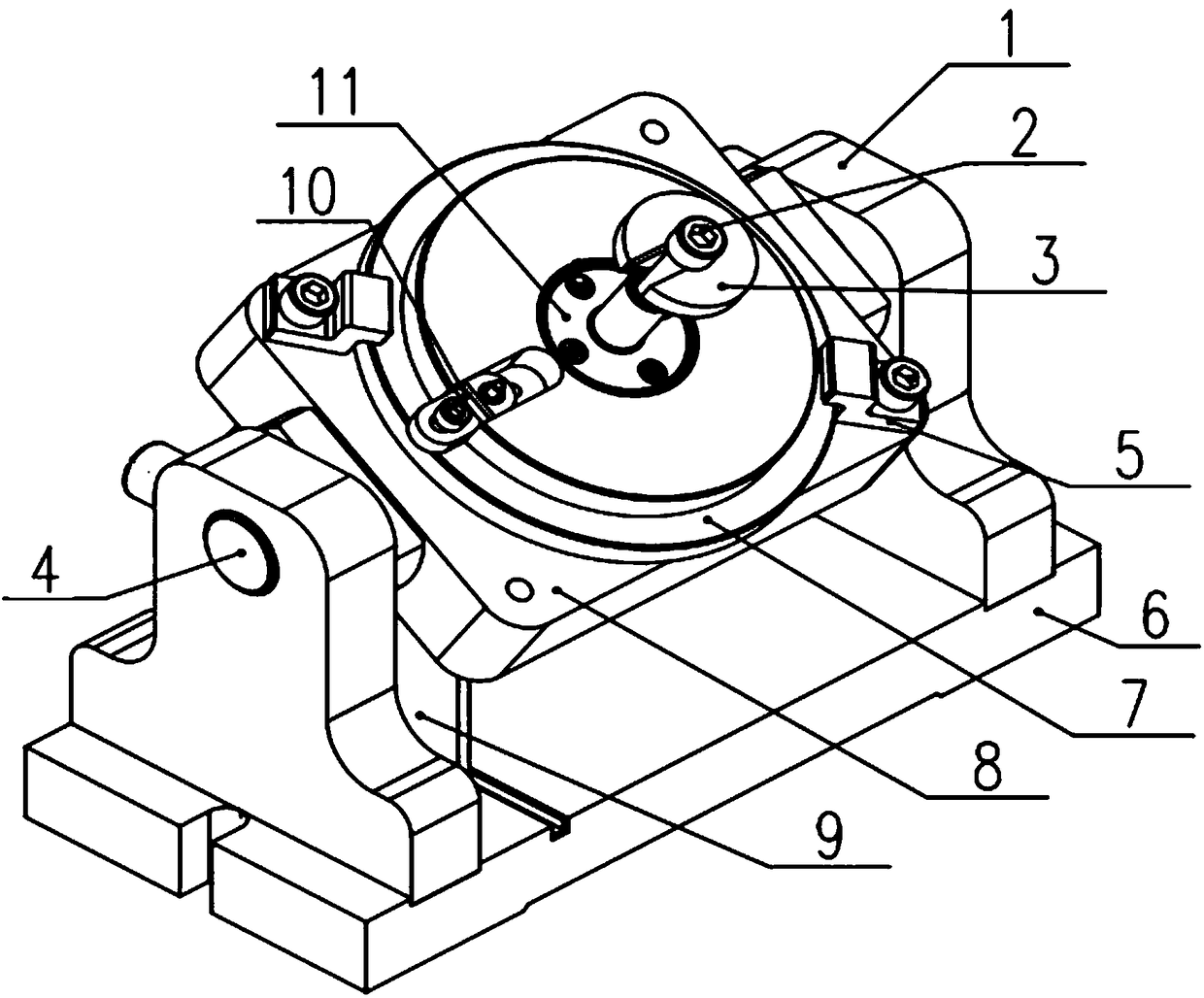

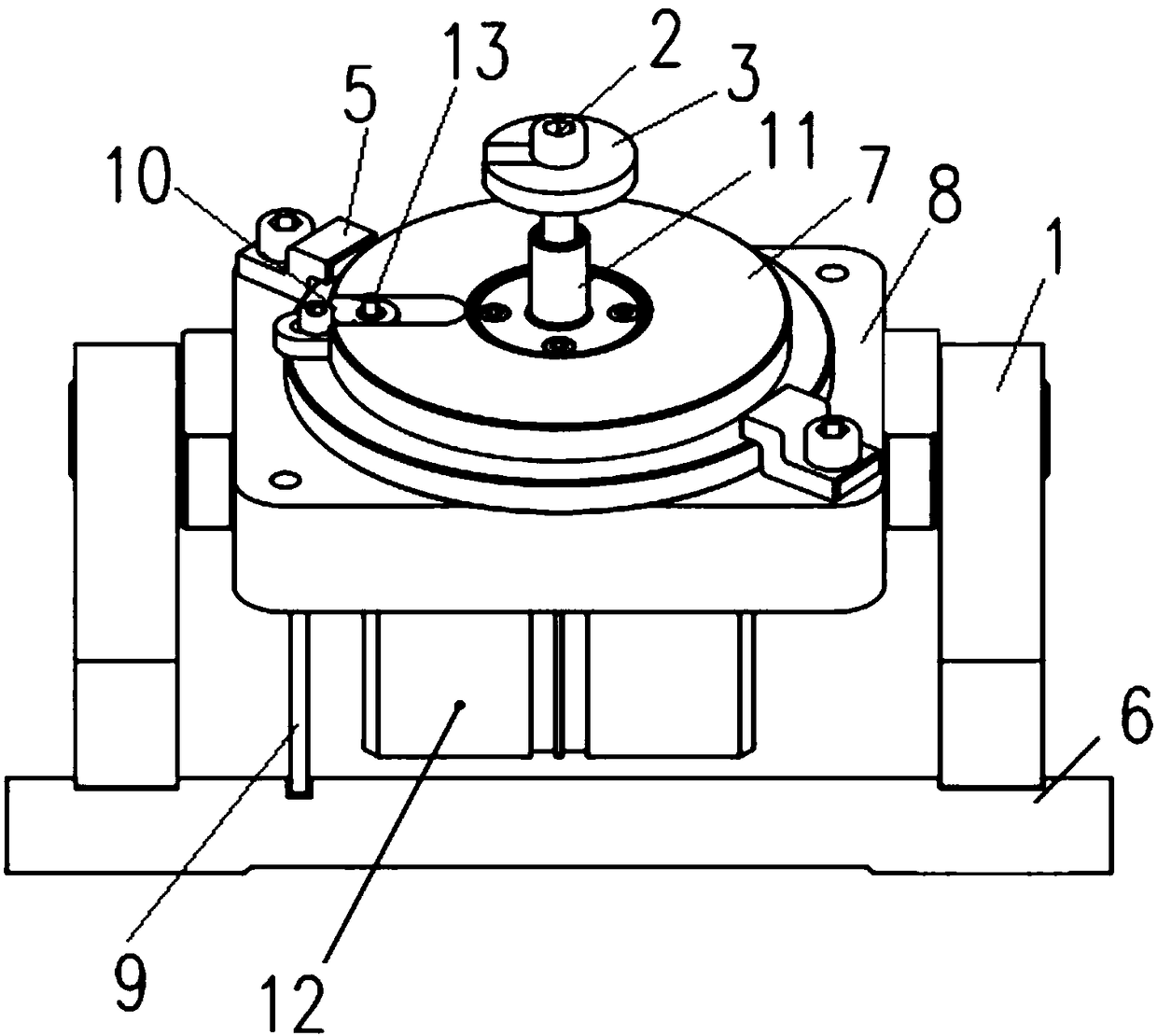

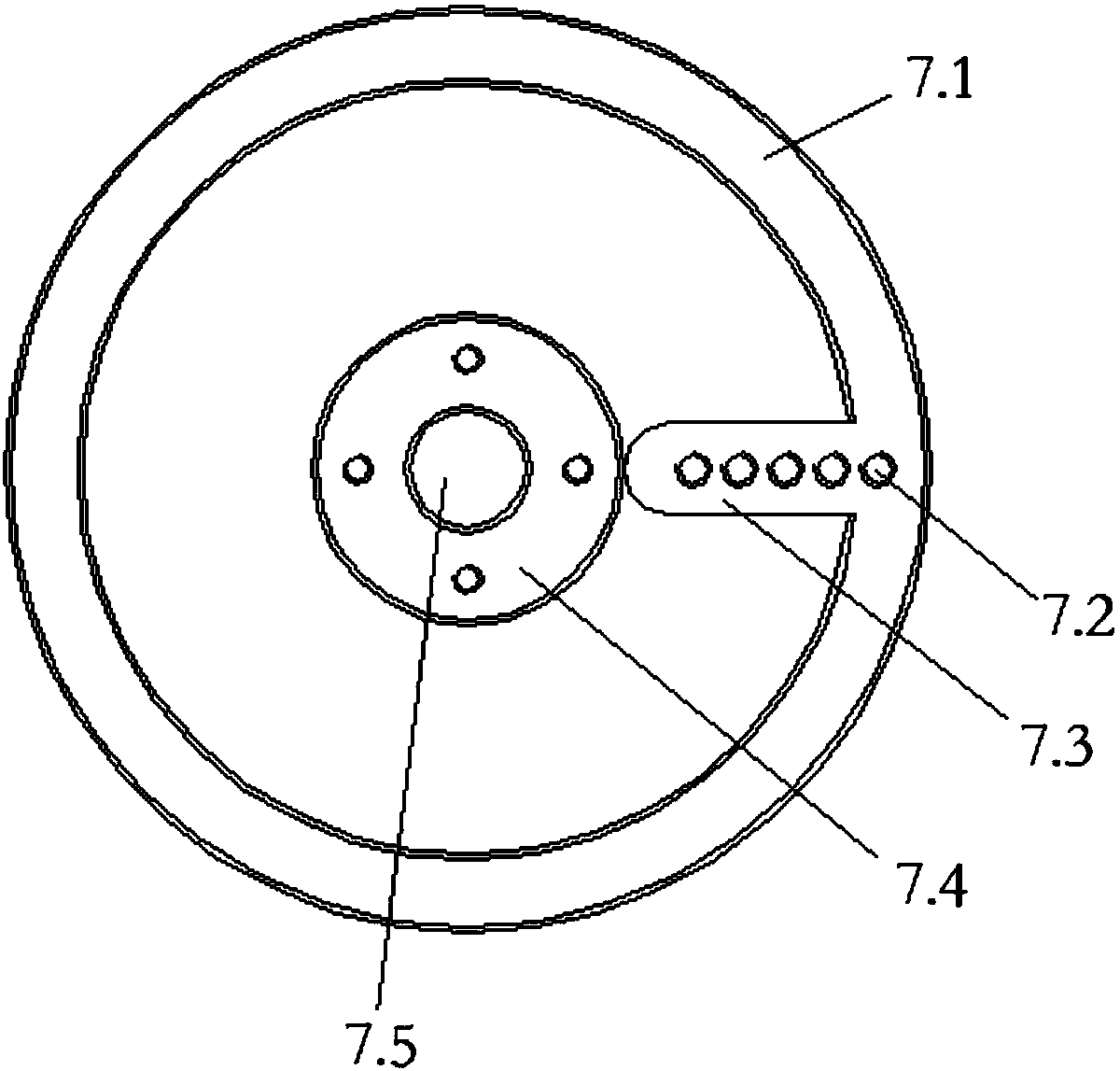

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as Figure 1-2 As shown, a processing fixture for a compressor cylinder includes vertical plates 1 symmetrically fixed at both ends of a bottom plate 6, and a rotating plate 8 is erected on the vertical plate 1 through a rotating shaft 4, so that the rotating plate 8 surrounds the The rotating shaft 4 rotates; the top surface movable frame of the rotating plate 8 is provided with a positioning flange 7, and the edge of the positioning flange 7 is compressed and fixed by a Z-shaped briquetting block 5 fixed on the rotating plate 8, and the briquetting block One end of 5 is fixed on the rotating plate by bolts, and the other end is pressed on the top surface of the positioning flange; the middle of the positioning flange 7 is connected with a positioning member 11 by bolts; the bottom end of the rotating plate 8 is equipped with a cylinder 12 , the piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com