Roller type vibration auxiliary polishing device and method

A polishing device and roller-shaped technology, used in grinding drive devices, grinding/polishing equipment, machine tools for surface polishing, etc., can solve the problems of low polishing efficiency and small application range, ensure uniformity and increase the usable range. , The effect of avoiding card loading errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

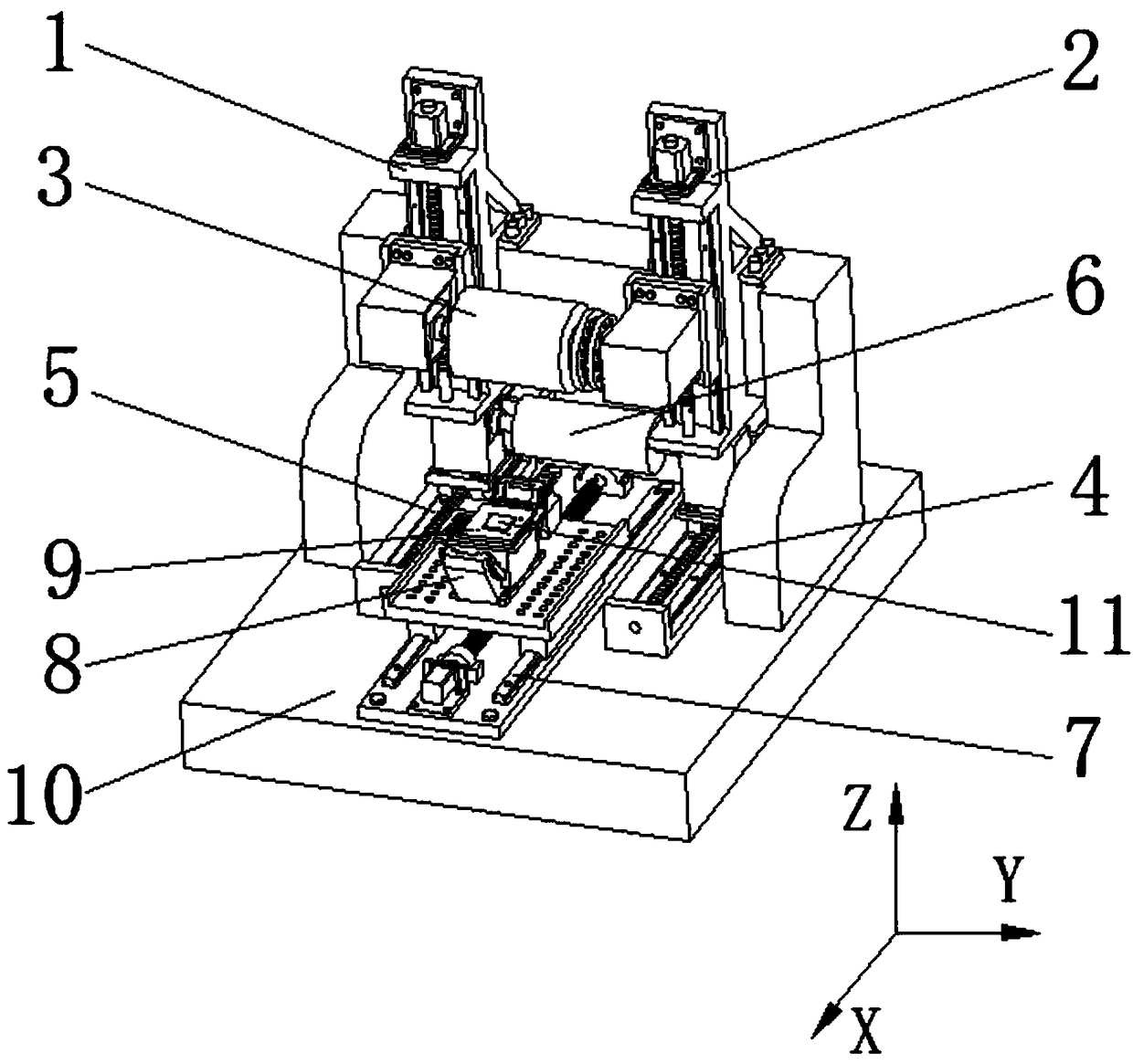

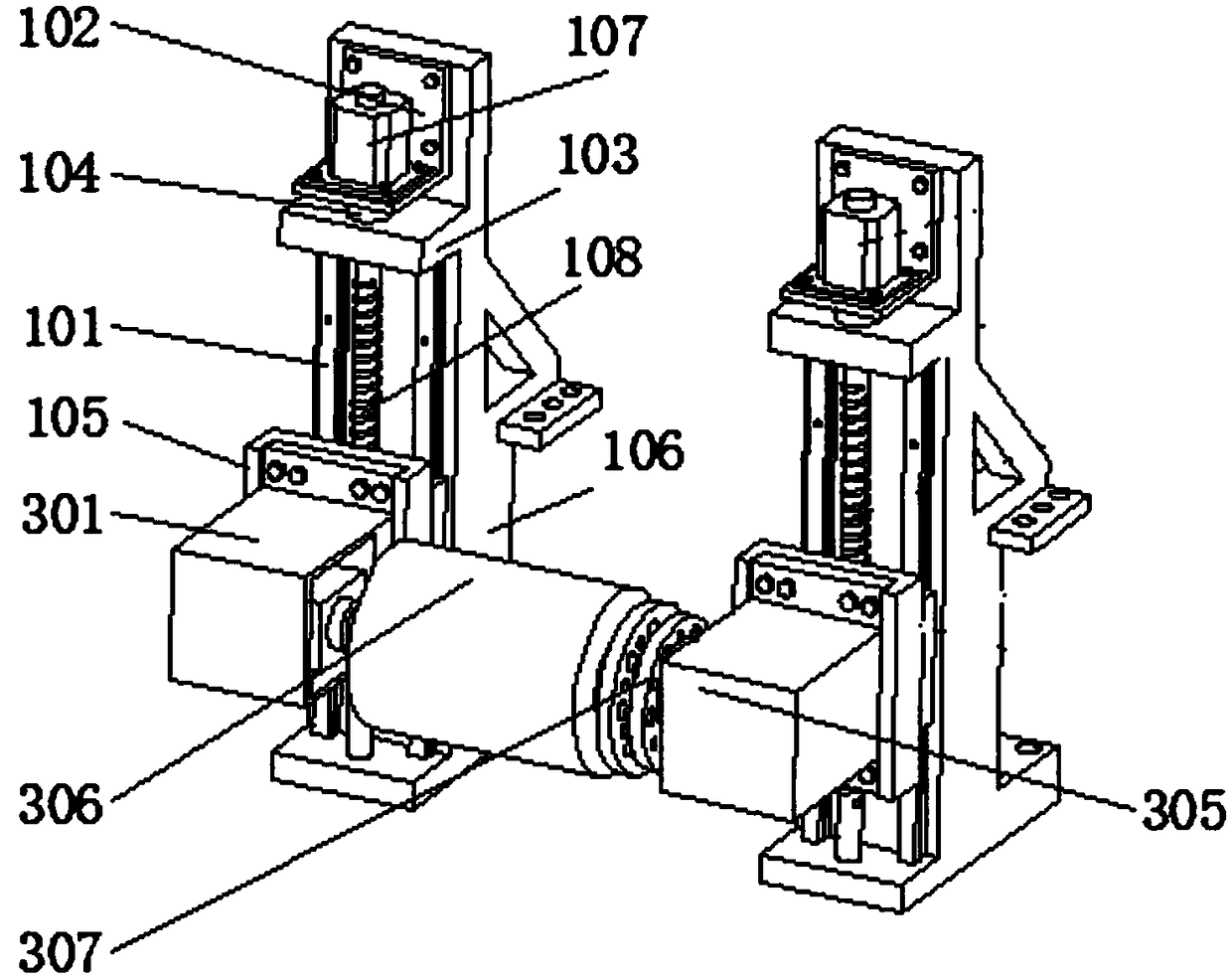

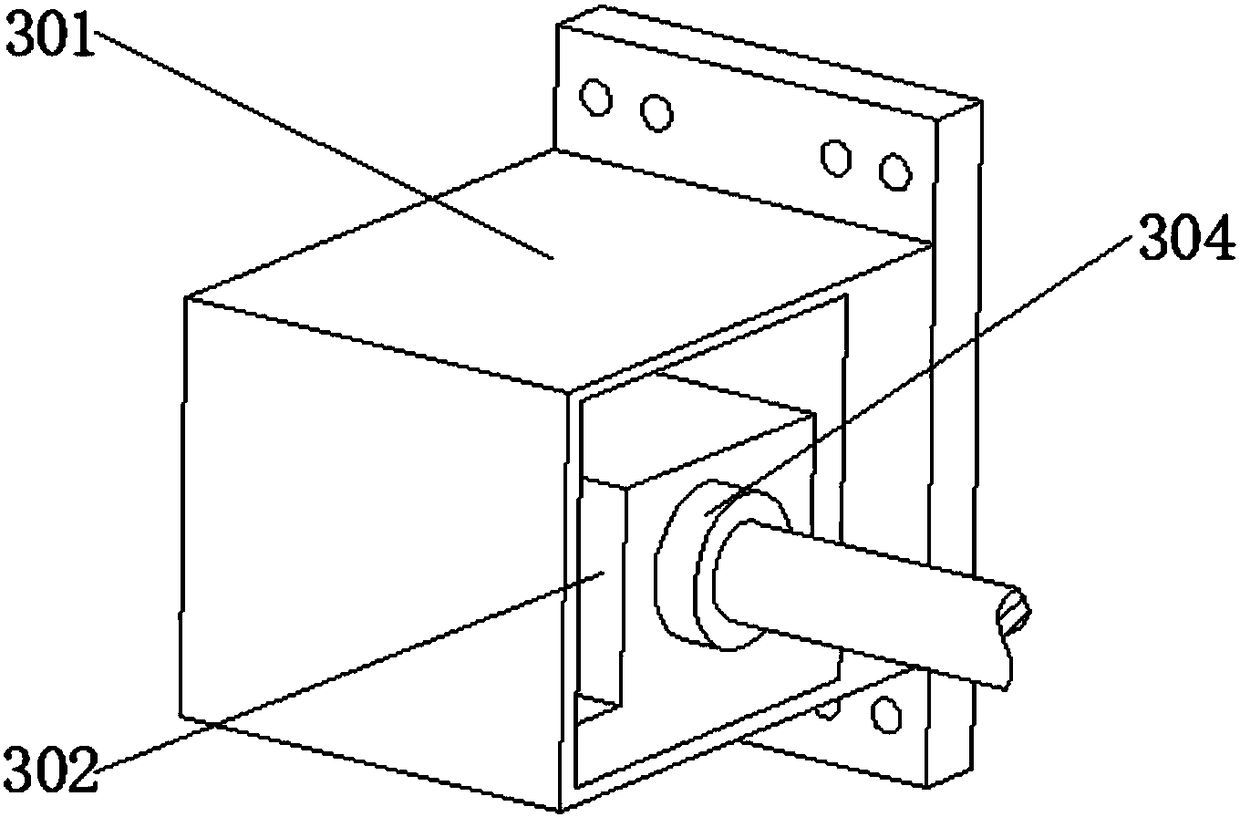

[0043] like figure 1 As shown, including Z-axis motion system 1, Z-axis motion system 2, Z-axis motion platform 3, X-axis motion system 1 4, X-axis motion system 2 5, X-axis motion platform 1 6, and X-axis motion system 3 7. X-direction motion platform 2 8, compound vibration platform 9, base platform 10, wherein Z-direction motion platform 3 is connected with Z-axis motion system 1 and Z-axis motion system 2 through screws, and Z-axis motion system 1 and Z Axis motion system 2 2 is connected with base platform 10 through screws, X-axis motion platform 1 6 is connected with X-axis motion system 1 4 and X-axis motion system 2 5 through screws, X-axis motion system 1 4 and X-axis motion system 2 5 Connected with the base platform 10 by screws, the X-direction motion platform 2 8 is connected with the X-axis motion system 3 7 by screws, the X-axis motion system 3 7 is connected with the base platform 10 by screws, and the polished workpiece 11 is glued to the compound vibration p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com