Novel liquid-crystal high-molecule material equipment

A liquid crystal polymer, a new type of technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve problems such as inaccurate installation and positioning, affecting product quality, and inability to effectively remove impurities. The effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

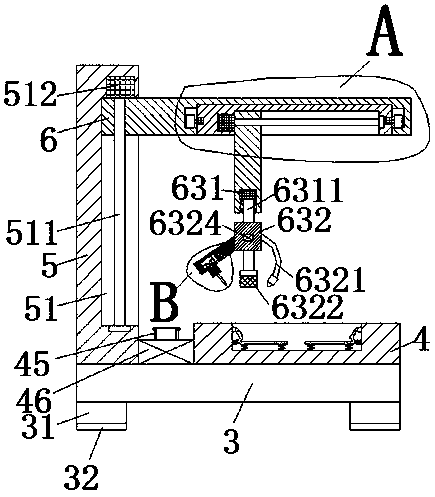

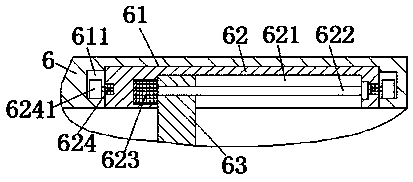

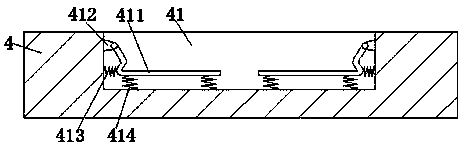

[0015] like Figure 1-Figure 5 As shown, a novel liquid crystal polymer material device of the present invention includes a chassis 3, a landing gear 5 disposed on the left side of the top end face of the chassis 3, and a material device disposed on the right side of the top end face of the chassis 3. Fixed base 4, the bottom end face of the underframe 3 is fixedly installed with a column 31, the bottom end face of the column 31 is fixedly installed with a protective rubber pad 32, the right end face of the landing gear 5 is provided with a first guide groove 51, the said A support plate 6 is slidably connected in the first guide groove 51 , and the right end of the support plate 6 protrudes out of the first guide groove 51 and is located above the material fixing seat 4 . The first guide groove The support plate 6 in 51 is connected with a first threaded rod 511 extending up and down, and the extended end of the bottom of the first threaded rod 511 is rotatably connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com