Cutting technology of standard board

A standard board and cutting technology, applied to paper/cardboard layered products, lamination devices, lamination auxiliary operations, etc., to achieve excellent compression resistance, excellent sound absorption, warmth and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

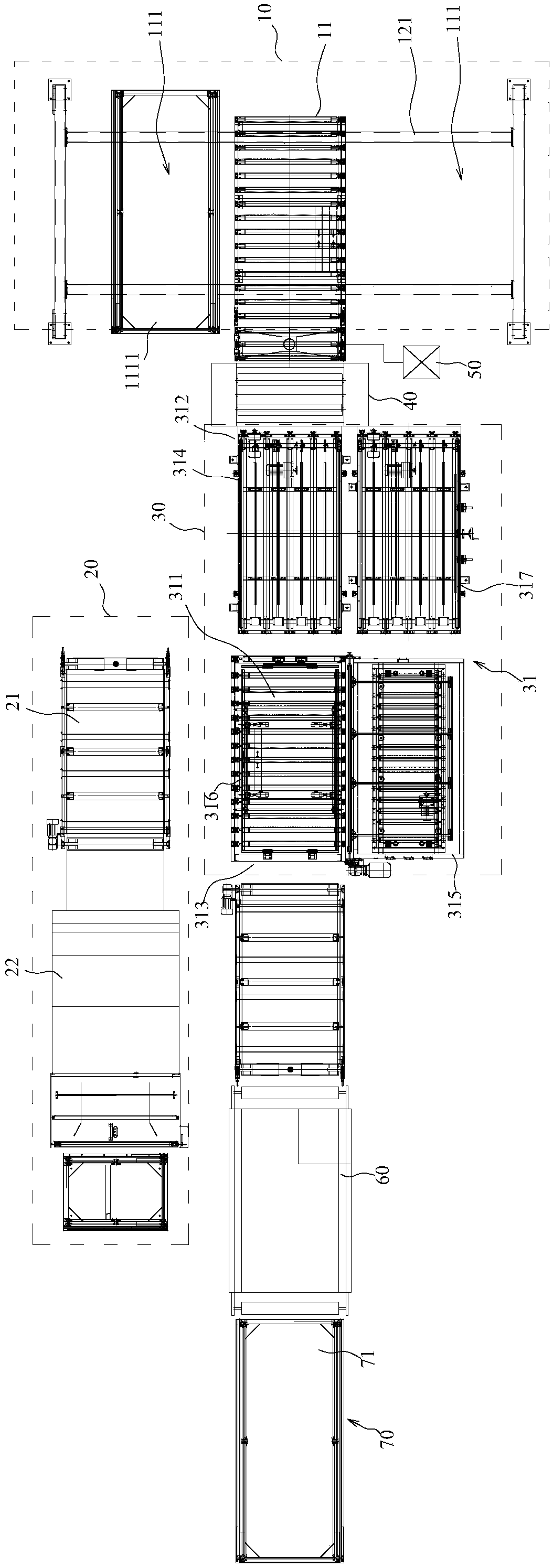

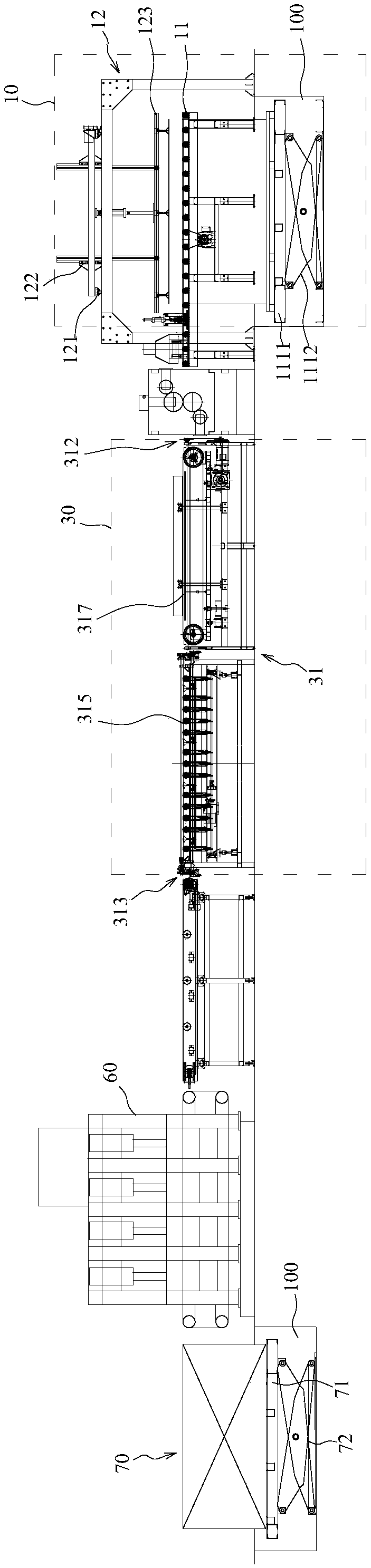

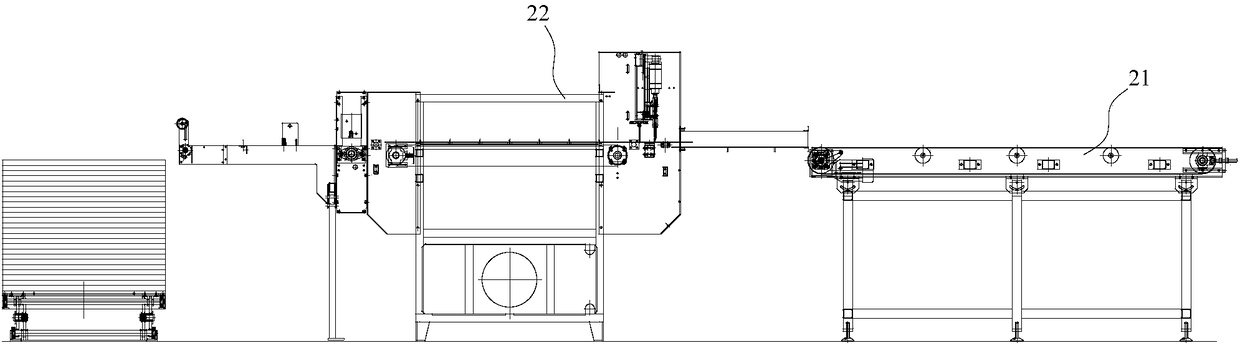

[0033] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0034] In order to apply the good performance of the honeycomb core layer to the board structure, so that the board can have good performances such as compression resistance, shock resistance, and sound absorption, the present invention provides a standard board cutting process, including:

[0035] Lower panel laying step: cutting and positioning the lower panel;

[0036] After the lower panel is cut to form the size of the required standard plate size, it is laid and fixed on the pressing station for pressing and forming the standard plate, so that the lower panel is at the lowest position of the standard plate structure;

[0037] Honeycomb core layi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com