Steam deicing vehicle

A deicing vehicle and steam technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of insufficient steam pressure, waste, and no steam recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

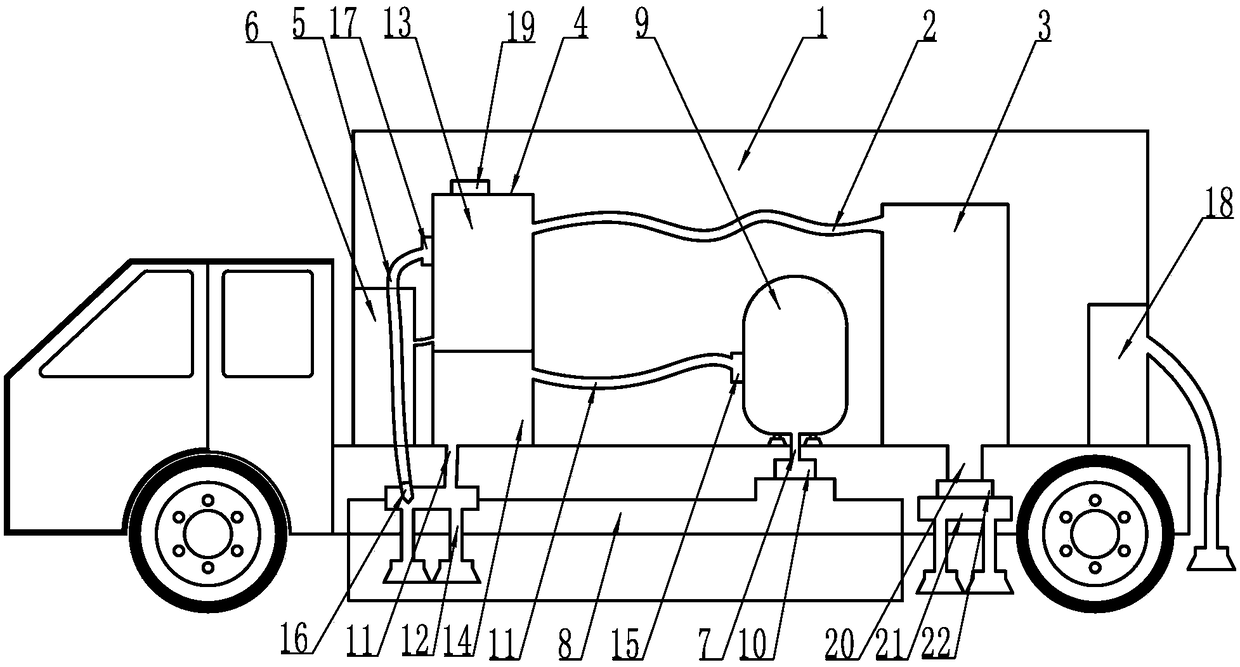

[0021] Such as figure 1 A steam deicing vehicle shown includes a vehicle body (1) and a steam deicing system, and is characterized in that the steam deicing system is set in the vehicle body (1), and the steam deicing system The system includes a water tank (3) connected through a water tank conduit (2) and a diesel boiler (4), the diesel boiler (4) is connected to the steam conduit (5), the diesel boiler (4) is connected to the oil tank (6) connected, the vehicle body (1) is provided with a steam recovery system, the steam recovery system includes a steam recovery cover (8) and an air storage tank (9) connected through a steam recovery pipe (7), and the The steam recovery pipe (7) is provided with a steam booster pump (10), the gas storage tank (9) is connected to the recovery steam output pipe (11), and the steam conduit (5) is connected to the recovery steam output pipe ( 11) Connected with the steam nozzle group (12), the steam recovery cover (8) is arranged at the bottom...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap