Spherical steam heat accumulator with wave guide guide mechanism

A guiding mechanism and waveguide technology, which is applied to heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of unsuitable spherical steam heat accumulator and easy damage of waveguide, so as to avoid pulling Impaired effects of stress and compressive stress, prolonging service life, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

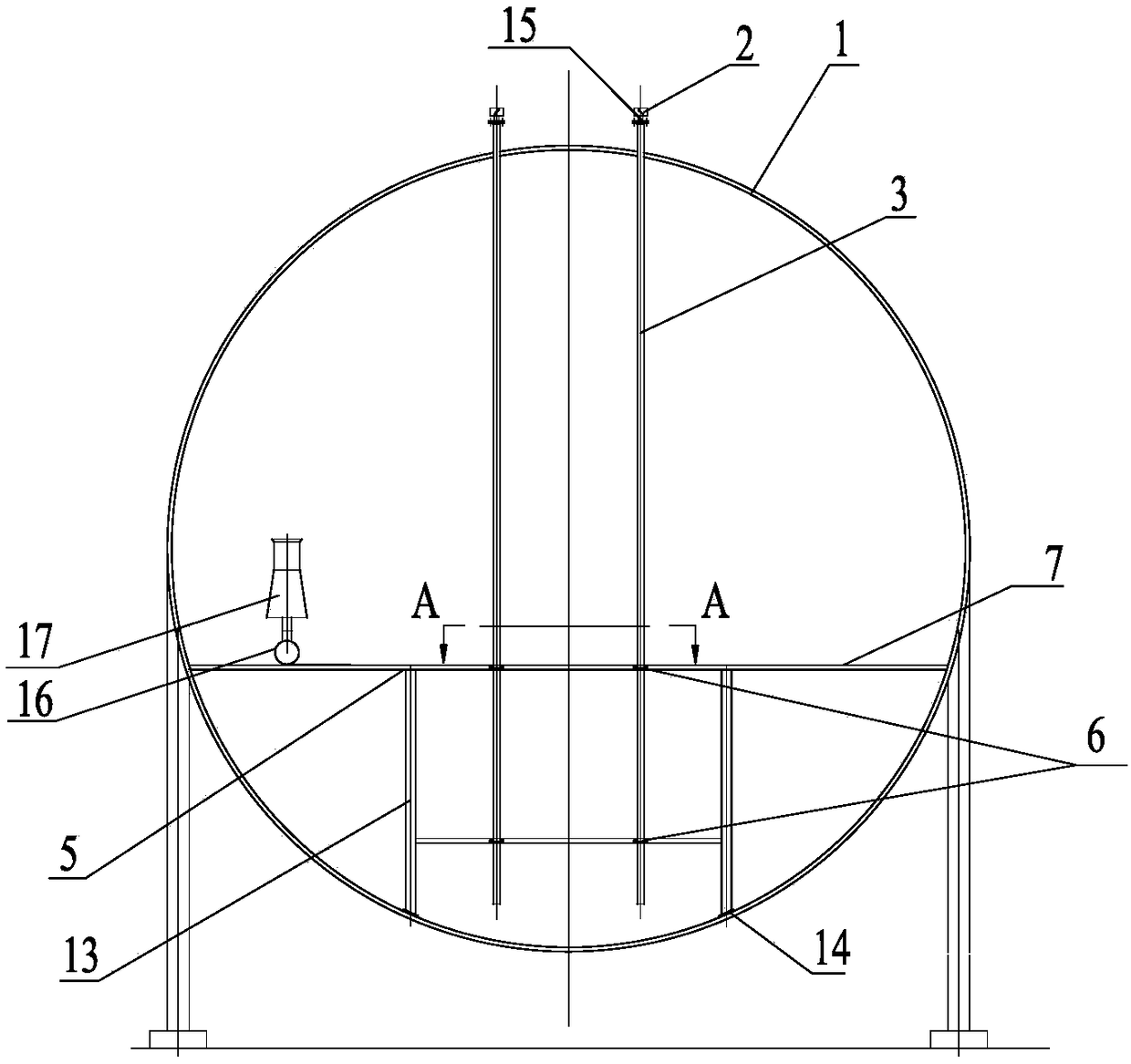

[0035] The details of the present invention can be understood more clearly with reference to the accompanying drawings and the description of specific embodiments of the present invention. However, the specific embodiments of the present invention described here are only for the purpose of explaining the present invention, and should not be construed as limiting the present invention in any way. Under the teaching of the present invention, the skilled person can conceive any possible modification based on the present invention, and these should be regarded as belonging to the scope of the present invention.

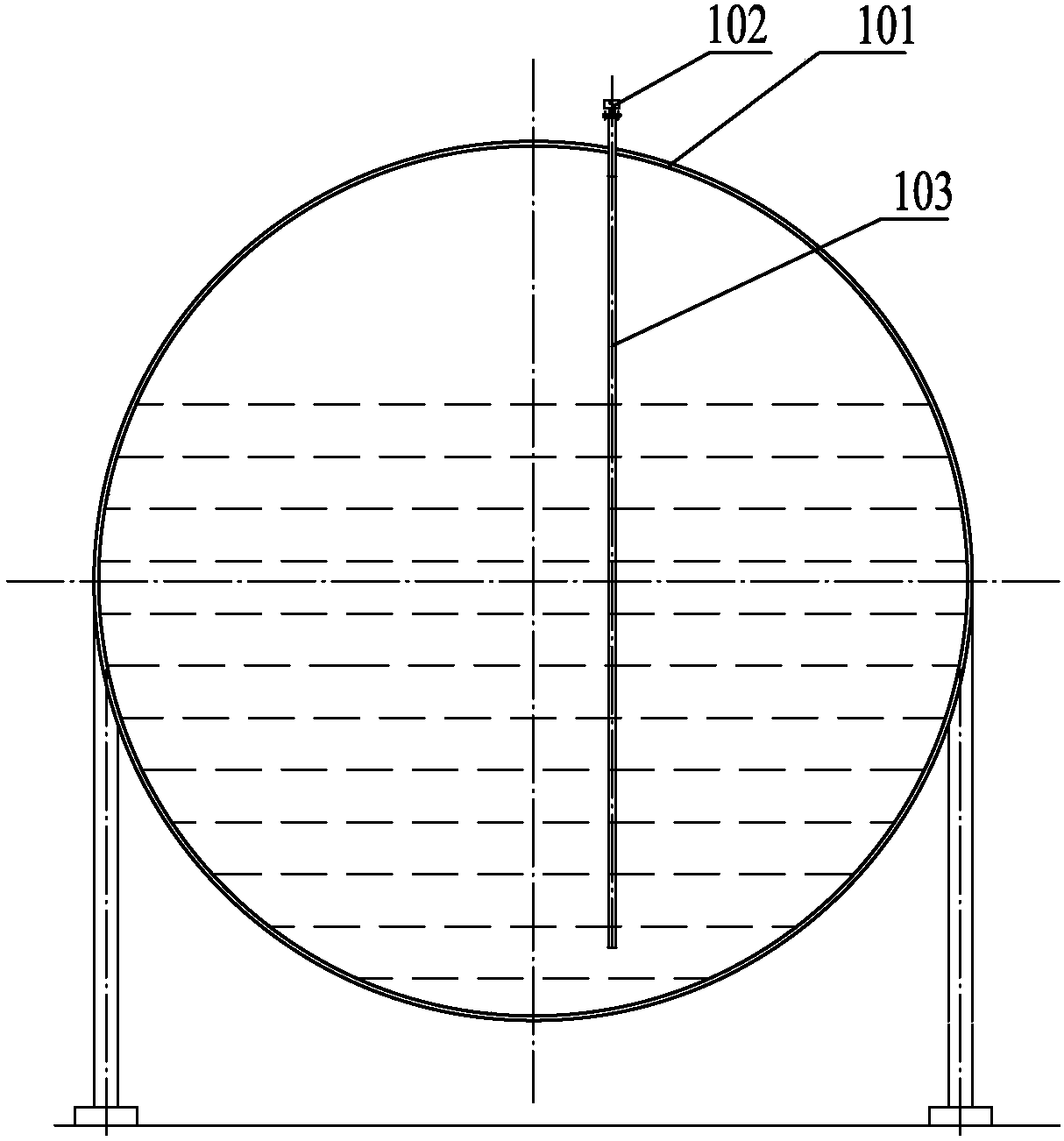

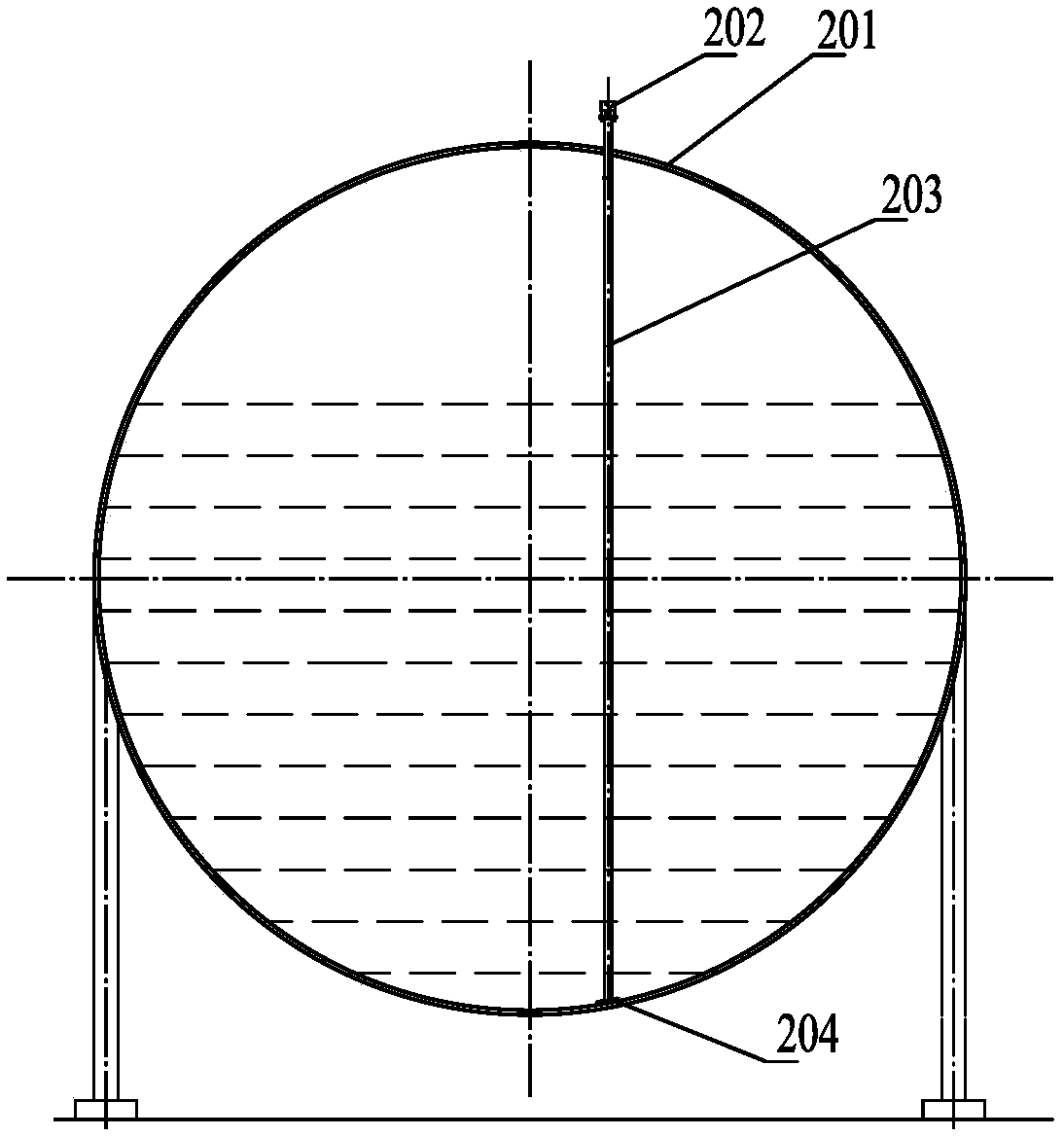

[0036] see image 3 As shown, it is a schematic cross-sectional structure diagram of the present invention, the present invention has a spherical steam accumulator with a waveguide guiding mechanism, including a spherical tank 1, two guided wave radar level gauges 2 and two waveguide 3, two The waveguide 3 extends from the top of the spherical tank 1 to the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com