High-speed multi-station shuttle manipulator device matched with heavy press

A multi-station, high-speed technology, applied in positioning devices, forming tools, feeding devices, etc., can solve the problems of inappropriate motor control methods, low repeatability of the manipulator, and long mold replacement time, reducing safety hazards and practicality. The effect of strong and stable transportation of sheet material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] When the traditional multi-station shuttle hand transports the sheet material, due to the low repeatability of the action, the transfer stroke is small, the transfer speed is low, the adjustment of the size of the conveyed product is not convenient enough, and the position of the sheet material changes during the conveying process. , brings troubles to subsequent processing and production, and the production efficiency is low. The main purpose of the present invention is to overcome the above-mentioned defects of the prior art and provide a high-speed multi-station shuttle with high automation level, high conveying efficiency, and high action repeatability.

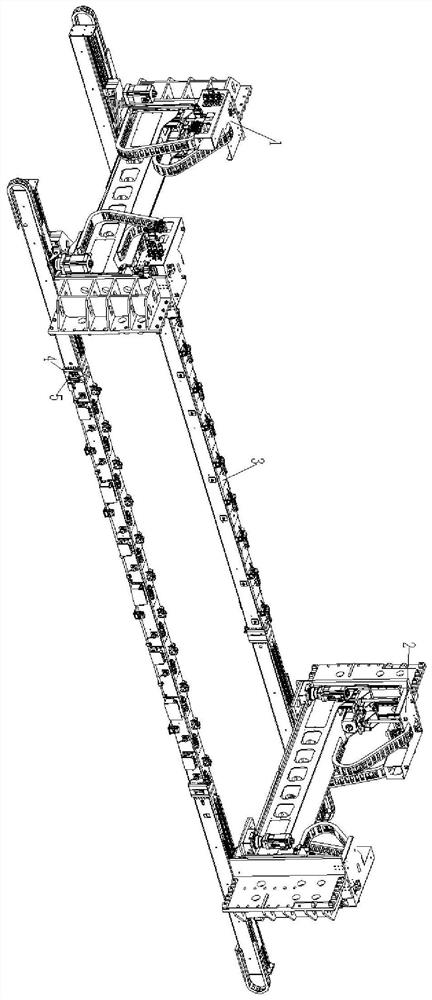

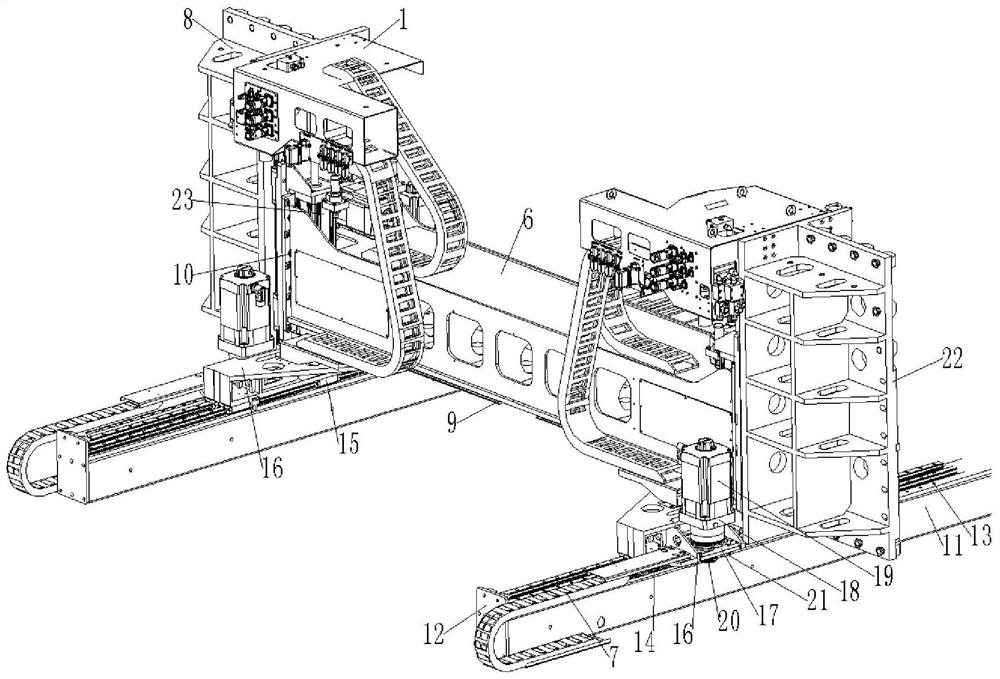

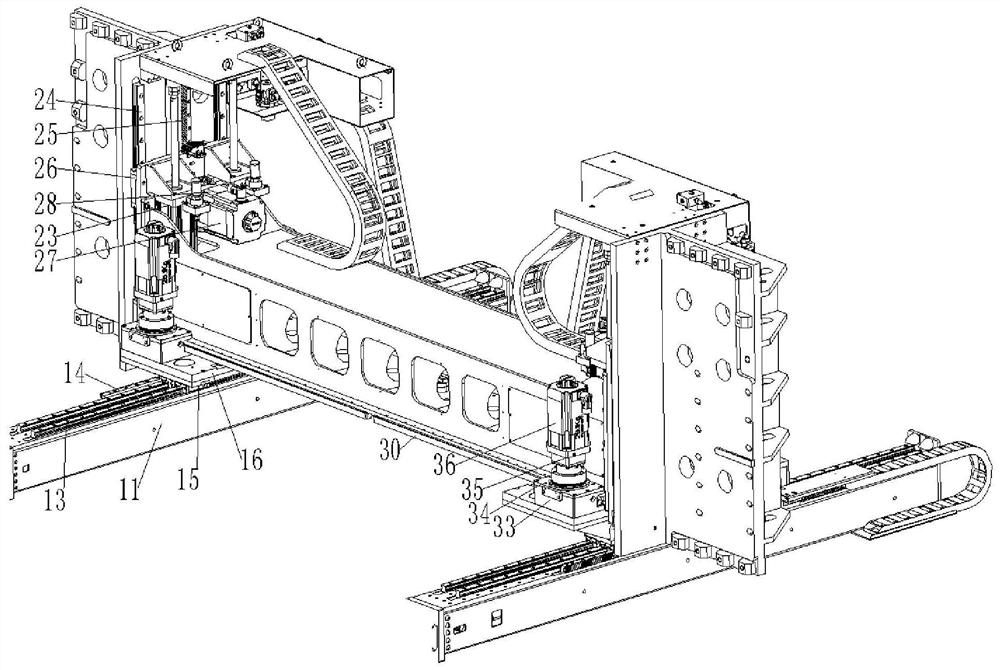

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 4 As shown, a high-speed multi-station shuttle hand device for a heavy-duty press, this device includes a loading side device 1, a blanking side device 2, and a cross bar for connecting the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com