Fatigue test bench of maize header

A fatigue test and header technology, which is used in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of time and site constraints, uneven quality of corn headers, and fatigue performance inspection of headers. The effect of improving product quality, saving test costs and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

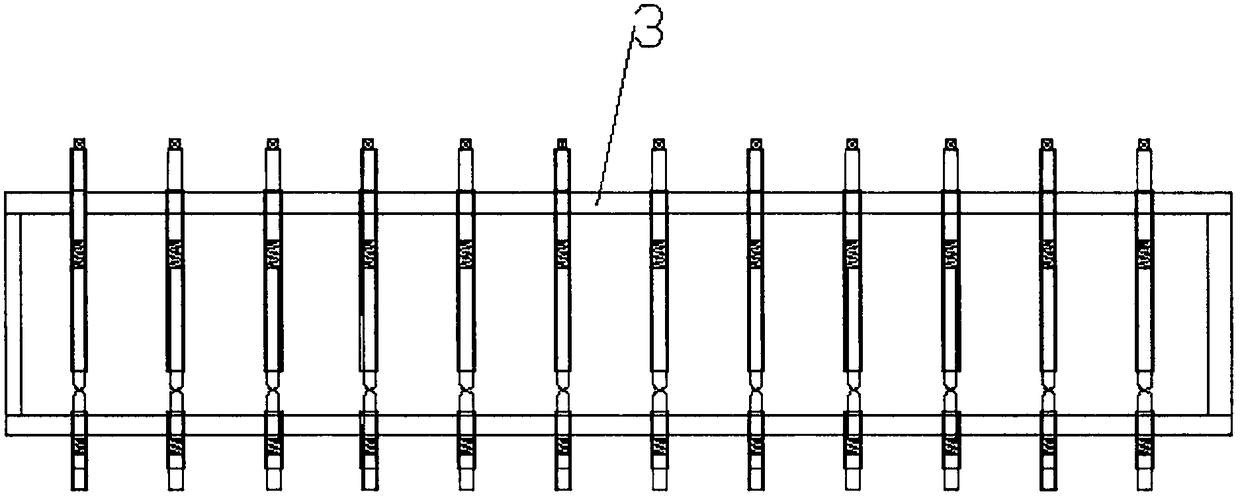

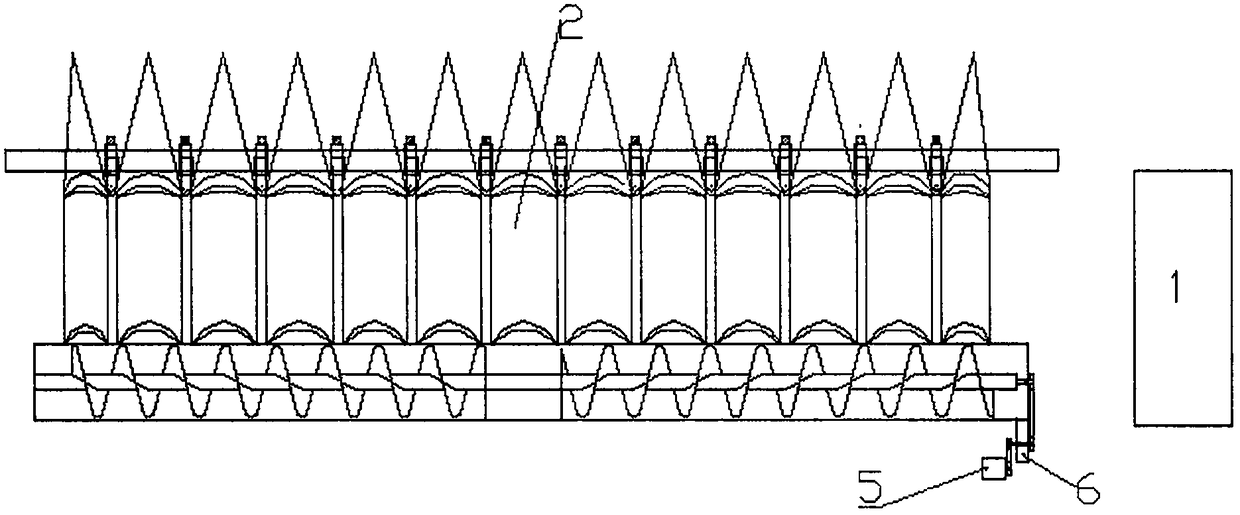

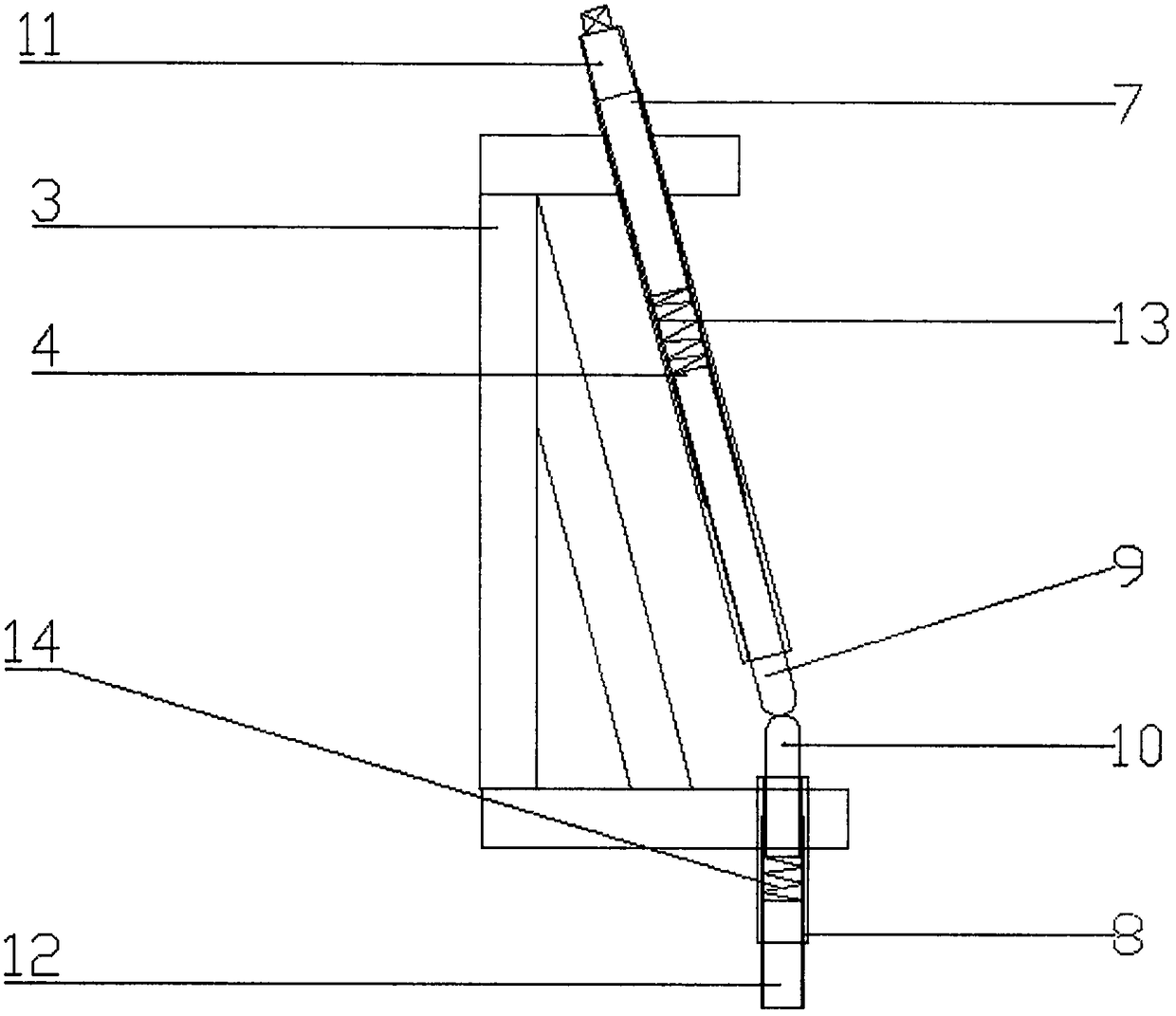

[0017] combine figure 1 , figure 2 and image 3 , the corn header fatigue test bench includes computer control system 1, the header fatigue test bench frame, and the nylon rod system for simulating corn stalks. The whole machine of the computer control system 1 adopts computer data acquisition and control, which has the advantages of accurate data acquisition and reliable control, and immediately controls the shutdown of the header when it is found to be faulty.

[0018] The header fatigue test bench frame includes a fixed bracket 3, on which a harvesting platform 2 is fixed, on which a motor 5 is installed, and the motor 5 is connected to the harvesting platform 2 through a transmission belt 6, and a threaded top is installed on the fixed bracket 3 Thread A11 and threaded top wire B12. A fixed guide tube A7 is installed on the threaded top screw A11. A spring A13 and a nylon rod A9 are arranged inside the fixed guide tube A7. A counting sensor 4 is installed inside the fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com