Control system and method of ground walking robot for routing inspection of power machine room

A walking robot and walking control technology, applied in the direction of control/regulation system, non-electric variable control, two-dimensional position/channel control, etc., can solve the problems of personal injury, difficulty in ensuring the accuracy of inspection, and low work efficiency. Achieve the effect of improving discovery ability and ensuring safe, reliable and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

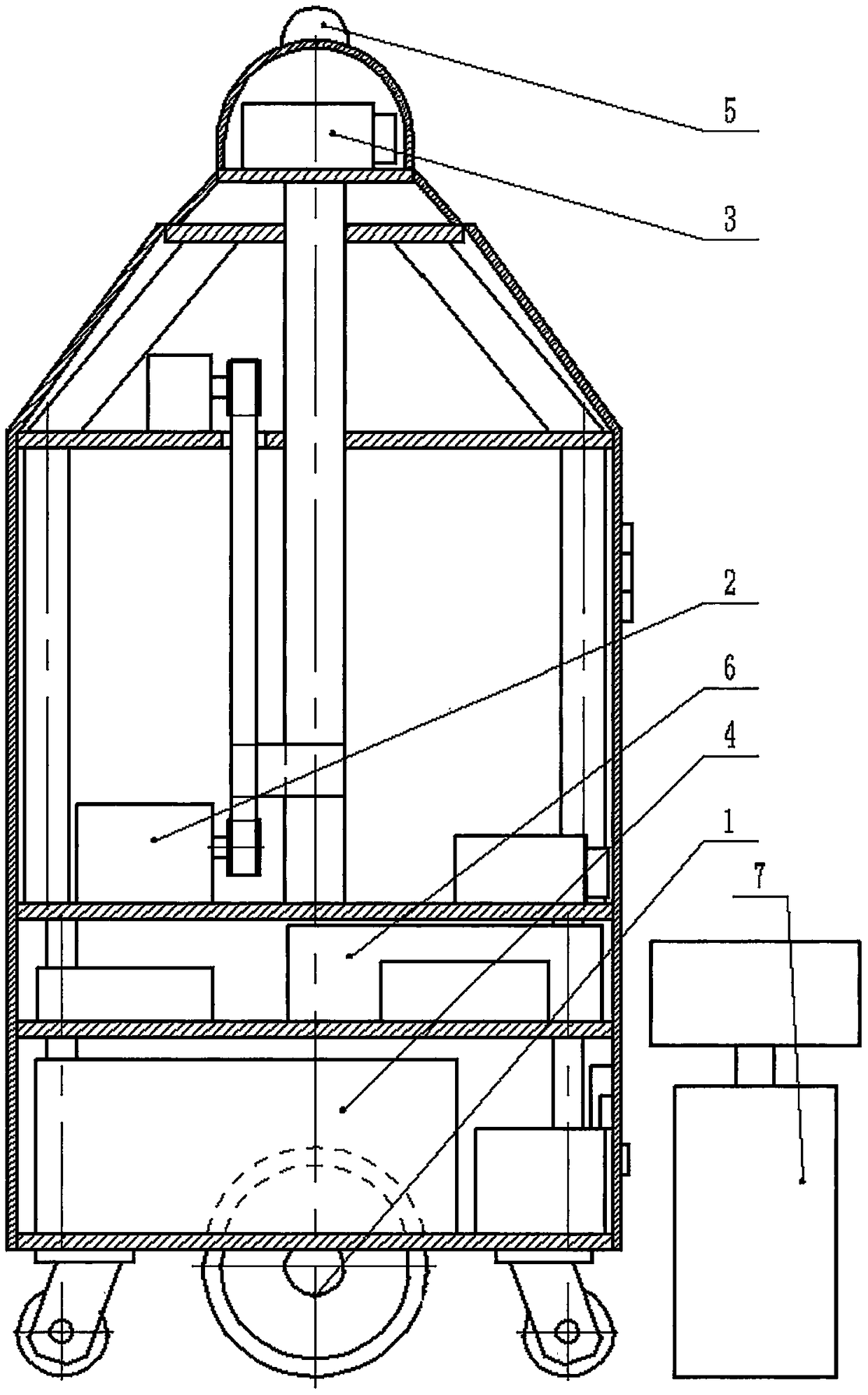

[0019] Such as figure 1 As shown, a control system and method for a ground walking robot used for inspection in an electric machine room, including a ground walking control system 1, a pan-tilt lifting control system 2, an inspection information collection system 3, a power supply system 4, and an alarm system 5 , the industrial control host 6 and the remote control platform 7, the ground walking control system 1 is made up of a walking motor drive controller, a power drive wheel device and a Kinect depth camera, and the walking motor drive controller receives the forward and backward signals sent by the industrial control host 6 , turn left, turn right and stop commands, the walking motor drive controller controls the power drive wheel device to perform forward, backward, left turn, right turn and stop actions, the Kinect depth camera senses and captures the surrounding environment information, senses and captures the device position information, sensing and ingesting the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com