A flexible work workshop scheduling method based on a stable and stable pairing strategy

A flexible operation and workshop scheduling technology, applied in the direction of control/adjustment system, program control, genetic law, etc., can solve the problem of not being able to provide a broad optimal scheduling plan, and achieve the effect of increasing diversity and good diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific drawings and embodiments.

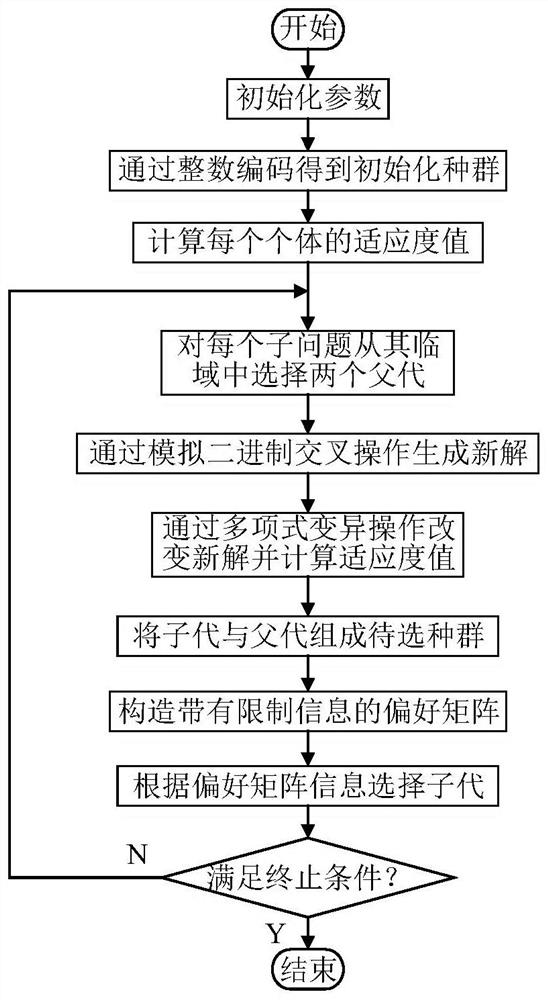

[0034] Such as figure 1 Shown: in order to obtain the production process scheduling scheme that is more in line with actual production, the present invention utilizes the method for solving multi-objective FJSP with limited stable pairing strategy to comprise the following steps:

[0035] a. Initialize relevant parameters and population

[0036] a1. Initialize various relevant parameters, including the target space dimension of the population including m=2, the number of chromosomes N=40, and the crossover probability P c =0.8, mutation probability P m =0.6, number of iterations K=400, neighborhood parameter T=5 and limit operator control parameter L=1;

[0037] a2. Set a group of uniformly distributed weight vectors w={ω 1 ,...,ω t ,...,ω N}, one of the vectors ω t =(ω t,1 ,…,ω t,l,…,ω t,m )∈R m ,ω t,l ≥0, and the set of subproblems P={p 1 ,...,p ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com