Novel radiating fin

A technology of heat sinks and heat dissipation fins, used in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. ability and thermal conductivity, and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

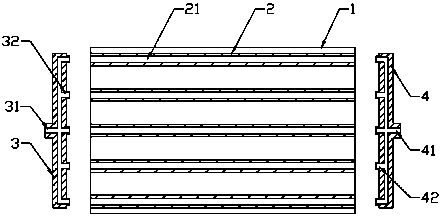

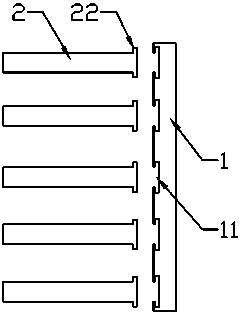

[0015] Such as figure 1 and figure 2 As shown, in this embodiment, the present invention includes a heat sink base plate 1 and a plurality of heat dissipation fins 2 arranged in parallel on the heat sink base plate 1, and deflectors 3 are respectively arranged on both sides of the heat dissipation fins 2 And the manifold 4, one side of the deflector 3 is provided with a total air inlet 31, and the other side is provided with some split air inlets 32 connected with the total air inlet 31, the manifold One side of 4 is provided with a general air outlet 41, and the other end is provided with a number of converging air outlets 42 connected with the general air outlet 41, and the middle parts of several of the cooling fins 2 are provided with cooling pipelines 21, the The split air inlet 32 and the converging air outlet 42 are cooperatively connected with the cooling pipeline 21 , and the general air inlet 31 and the general air outlet 41 are both connected to an external liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com