A method for preparing low-order coal slime heteropolar collector by modification of hydrocarbon oil

A technology of hydrocarbon oil and collector, applied in solid separation, flotation and other directions, can solve the problems of weak recovery capacity, high price, complex preparation process, etc., achieve low cost, reduce flotation cost, and simple modification process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

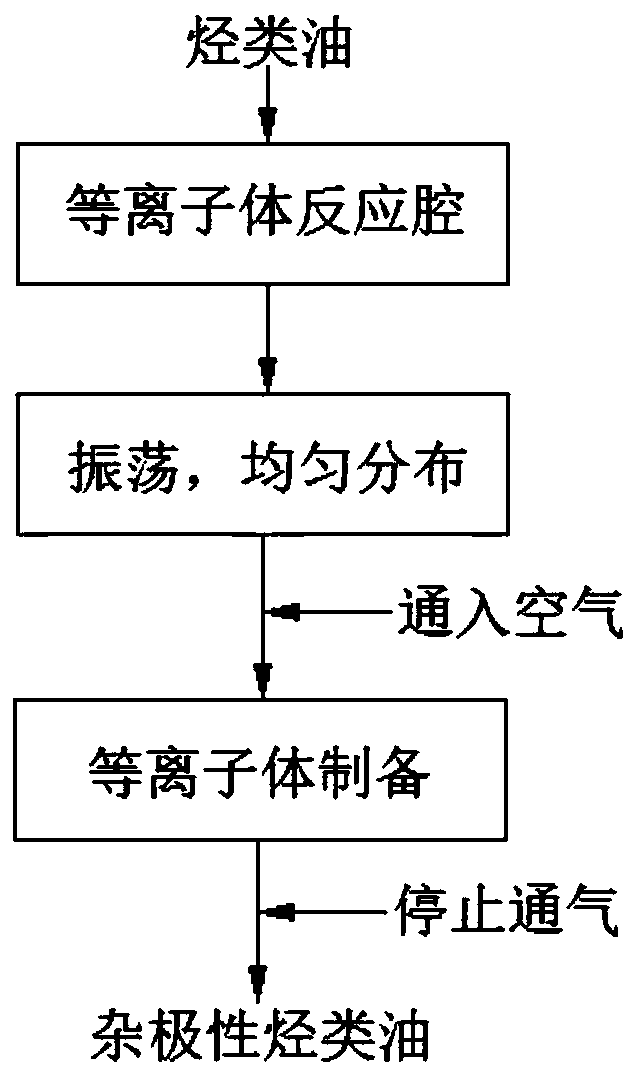

Method used

Image

Examples

Embodiment 1

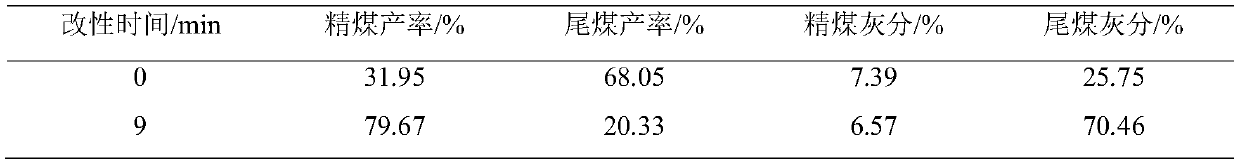

[0049] Example 1: A method for preparing a low-order coal slime heteropolar collector by modifying hydrocarbon oil. The raw material is conventional diesel oil, the plasma reactor is CTP-2000K, and a dielectric barrier discharge reactor is used to generate low-temperature plasma at normal temperature and pressure. The preparation process is:

[0050] 1. Feed diesel into the low-temperature plasma reaction chamber, and the liquid level is lower than the air inlet;

[0051] 2. After the air inlet is blocked, place it in the HY-4 speed-adjustable multi-purpose oscillator for 5 minutes;

[0052] 3. Fix the low-temperature plasma reaction chamber between the two media of the plasma reactor, and open the air inlet;

[0053] 4. Connect the gas circuit to the inlet gas of the reaction chamber, turn on the gas pump and let the flow rate be 30L / (min.m 2 )air;

[0054] 5. Turn on the low-temperature plasma reactor, adjust the output power to 100W, and the working current to 2-3A to g...

Embodiment 2

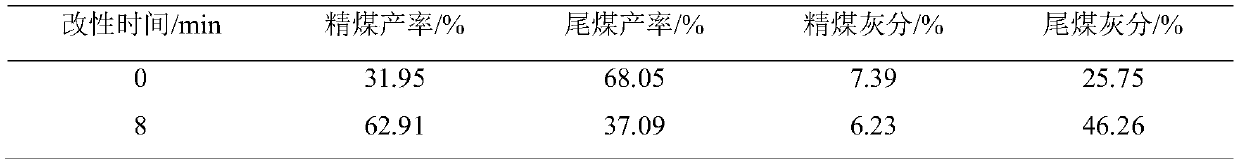

[0061] Example 2: A method for preparing a low-order coal slime heteropolar collector by modifying hydrocarbon oil. The raw material is conventional kerosene, the plasma reactor is CTP-2000K, and a dielectric barrier discharge reactor is used to generate low-temperature plasma at normal temperature and pressure. The preparation process is:

[0062] 1. Feed kerosene into the low-temperature plasma reaction chamber, and the liquid level is lower than the air inlet;

[0063] 2. After the air inlet is blocked, place it in the HY-4 speed-adjustable multi-purpose oscillator for 5 minutes;

[0064] 3. Fix the low-temperature plasma reaction chamber between the two media of the plasma reactor, and open the air inlet;

[0065] 4. Connect the gas circuit to the inlet gas of the reaction chamber, turn on the gas pump and let the flow rate be 30L / (min.m 2 )air;

[0066] 5. Turn on the low-temperature plasma reactor, adjust the output power to 100W, and the working current to 2-3A to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com