A device for continuous directional solidification of alloy castings with ultra-strong traveling wave magnetic field

A technology of directional solidification and traveling wave magnetic field, applied in the field of solidification equipment, can solve problems such as loss, and achieve the effect of eliminating shrinkage porosity, reducing cost and improving casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

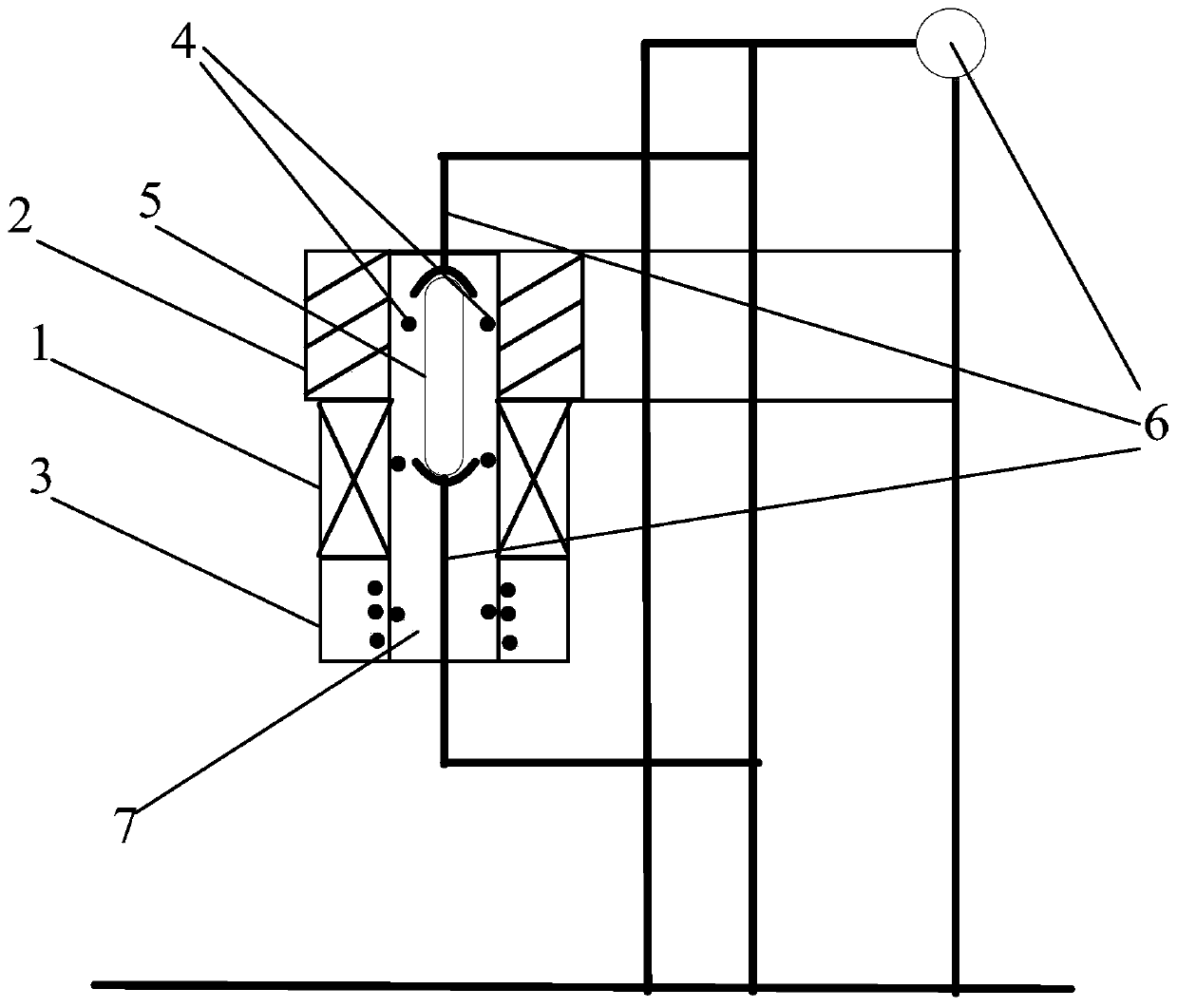

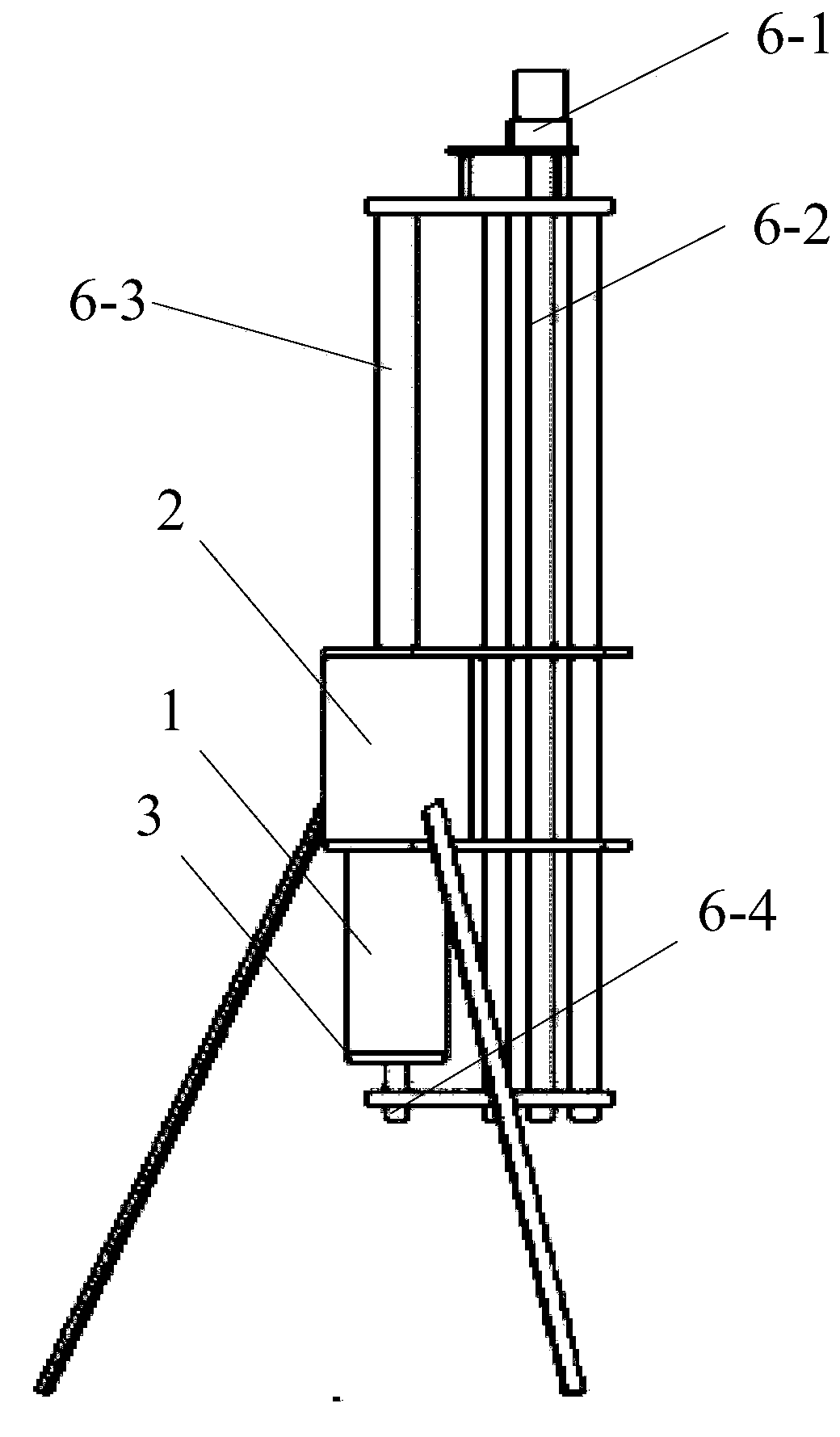

[0022] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment comprises super-forced traveling wave magnetic field generating device (1), smelting and heat preservation device (2), cooling crystallization device (3), crucible (5), motor moving device (6) and several temperature measuring devices (4), the smelting and heat preservation device (2), the ultra-strong traveling wave magnetic field generating device (1) and the cooling and crystallization device (3) are arranged sequentially from top to bottom, the inner cavity of the smelting and heat preservation device (2), the super-forced The inner cavity of the wave magnetic field generating device (1) and the inner cavity of the cooling crystallization device (3) are a connected cavity (7), the crucible (5) is located in the cavity (7), and the crucible (5) and the motor The moving device (6) is connected, and several temperature measuring devices (4) are evenly distributed...

specific Embodiment approach 2

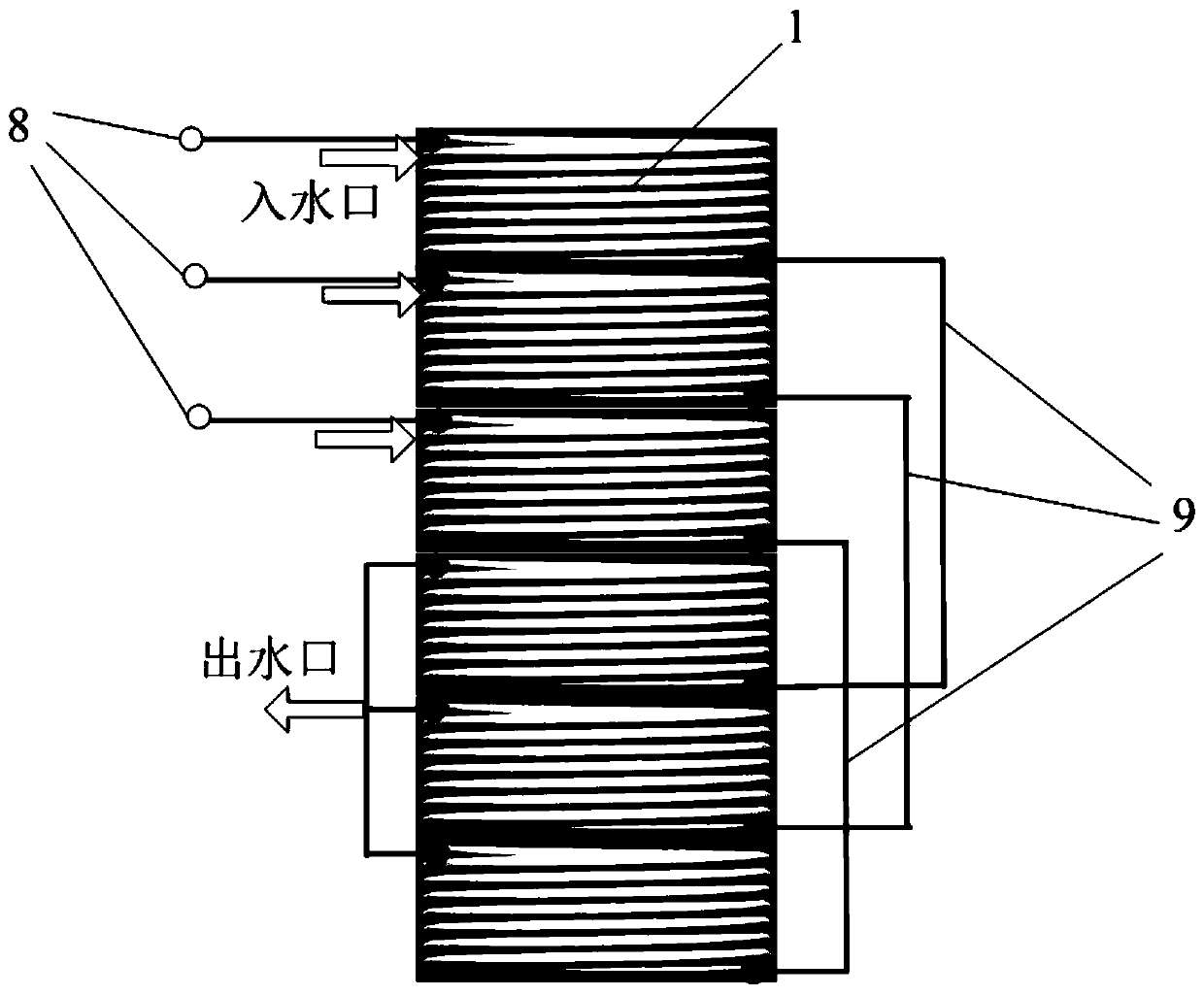

[0023] Specific implementation mode two: combination image 3 Describe the present embodiment, the present embodiment is that the ultra-forced traveling wave magnetic field generating device (1) is made up of six groups of coils, two of the six groups of coils are connected in series, and are connected to the three-phase power supply in a star connection, and the voltage, current and frequency can be adjusted The coil is made of hollow copper tube material, and the circulating cooling water is passed into the tube, and the water flow speed is controlled by the water pump, so as to control the cooling effect, integrate cooling and magnetism, and improve the working limit and working time of the super traveling wave magnetic field generating device (1). Achieve the acquisition of ultra-strong traveling wave magnetic field treatment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 Describe this embodiment, this embodiment is that the smelting and heat preservation device (2) is made of graphite heat preservation sleeve, and a resistance wire heating system is added in the graphite heat preservation sleeve, in order to melt the alloy in this area and ensure that the alloy melt is here higher temperature in the region. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com