A kind of preparation method of tartaric acid/tylosin phosphate

A technology of tylosin phosphate and tylosin, which can be used in the preparation of sugar derivatives, chemical instruments and methods, organic chemistry, etc., and can solve the problems that impurities cannot be effectively separated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of tartaric acid / tylosin phosphate, comprising steps as follows:

[0034] Tylosin fermentation broth volume 10m 3 , titer 12386U / mL, total billion is 123.9. Add polyaluminum chloride, the weight ratio of polyaluminum chloride to fermentation broth is 1.0±0.3% (w / w), and stir for 25±5 minutes. Filter the fermentation broth with a plate and frame filter, control the feed pressure to 0.3MPa, and obtain the filtrate after pressure filtration, which is the tylosin filtrate with a volume of 12m 3 , the titer is 9621U / mL.

[0035] The sodium hydroxide solution with a mass concentration of 3% and the filtrate are pumped into the mixer at the same time, the pH is controlled at 7.7, and the mixed feed liquid is injected into a centrifuge and centrifuged at a speed of 4500 rpm for 2 seconds to obtain purified After the filtrate; send the purified filtrate, butyl acetate and liquid caustic soda into the mixer to mix, adjust the pH value in the range of 9.8, ...

Embodiment 2

[0037] A preparation method of tartaric acid / tylosin phosphate, comprising steps as follows:

[0038] Tylosin fermentation broth volume 9.5m 3 , titer 13194U / mL, total billion is 126.9. A polyaluminum chloride solution with a mass concentration of 20-22% is added, the mass volume ratio of the polyaluminum chloride solution to the fermentation broth is 0.6% (w / v), and the mixture is stirred for 40 minutes. Filter the fermentation broth with a plate and frame filter, control the pressure of the filter press to 4.0MPa, and obtain the filtrate after the press filter, which is the tylosin filtrate with a volume of 11m 3 , the titer is 10832U / mL.

[0039] The sodium hydroxide solution with a mass concentration of 4wt% and the filtrate are pumped into the mixer at the same time, the pH is controlled at 7.9, and the mixed feed liquid is injected into the centrifuge and centrifuged at a speed of 4800 rpm for 2s to obtain Purified filtrate; send the purified filtrate, butyl acetate, ...

Embodiment 3

[0041] A kind of preparation method of tartaric acid / tylosin phosphate, described in embodiment 1, difference is:

[0042] The sodium hydroxide solution with a mass concentration of 3wt% and the filtrate are pumped into the mixer at the same time, the pH is controlled at 7.54, and the extraction is carried out after centrifugation.

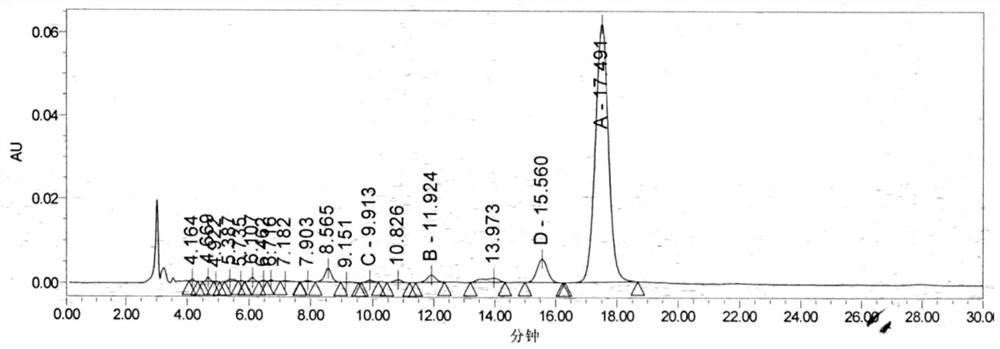

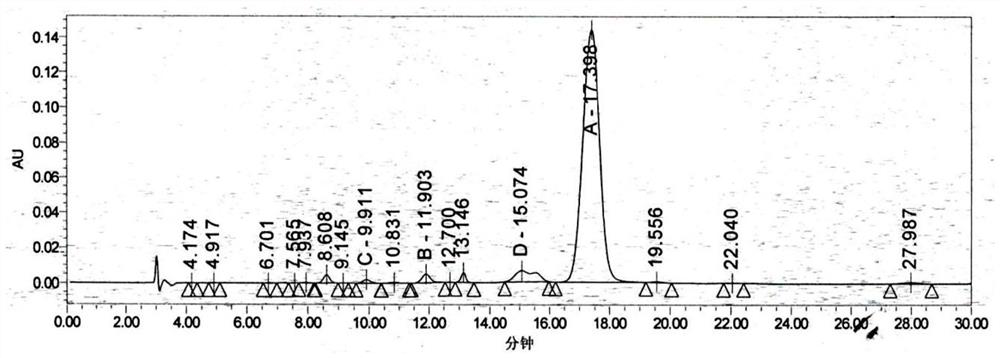

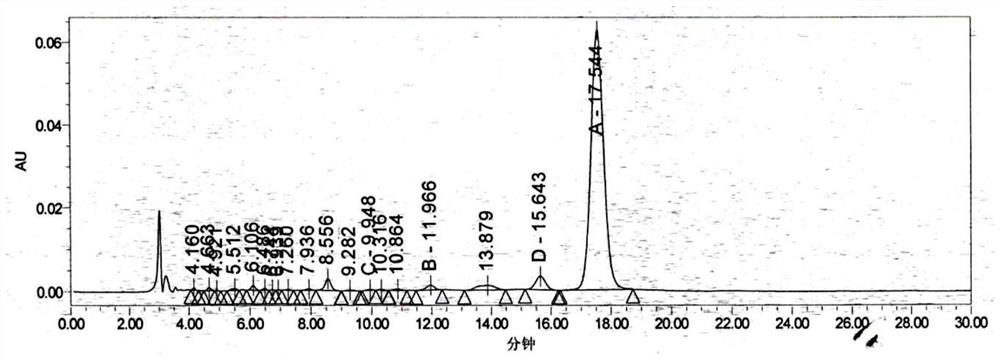

[0043] pass figure 1 and figure 2 Contrast, it can be clearly seen that the impurity peaks in the chromatogram of the filtrate after purification are significantly less than figure 1 ,pass image 3 and Figure 4 Contrast, it can be clearly seen that the impurity peaks in the chromatogram of the filtrate after purification are significantly less than image 3 ,pass Figure 5 and Figure 6 Contrast, it can be clearly seen that the impurity peaks in the chromatogram of the filtrate after purification are significantly less than Figure 5 , Therefore, after the purification process of the present invention, it can be confirmed by HPLC that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com