UV offset printing water-based varnish composition and preparation method thereof

An offset printing, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of coating embossing resistance and temperature resistance, low VOC emissions, environmental pollution, etc., and achieve no embossing Adhesion risk, low VOC, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

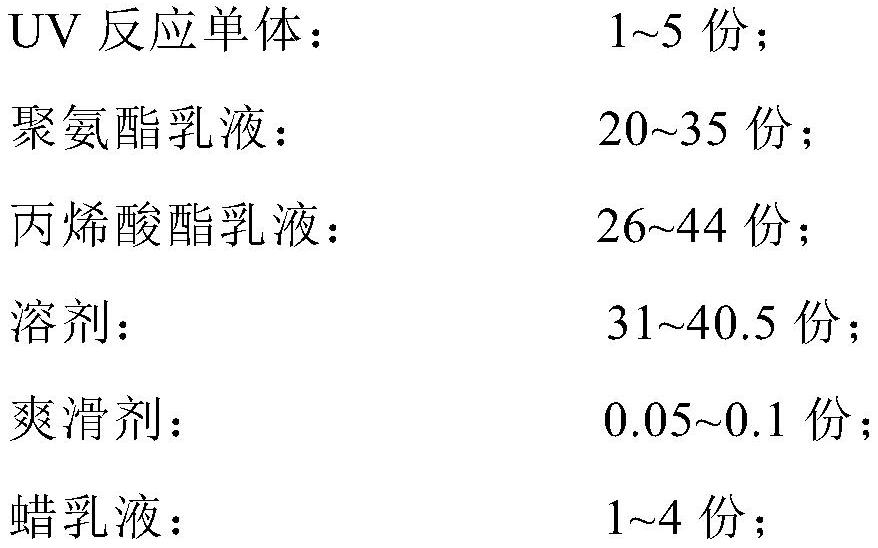

Method used

Image

Examples

Embodiment 1

[0027] Table 1

[0028] UV reactive monomer 1 polyurethane emulsion 20 Acrylic Emulsion 44 Ethanol: water = 3:1 34 slip agent 0.1 wax emulsion 1 D 0.2 Defoamer 0.2

[0029] The formula of the UV offset printing aqueous varnish composition of the present embodiment is as shown in table 1, and preparation method comprises the steps:

[0030] After mixing the acrylate emulsion, polyurethane emulsion and UV reactive monomer, add the solvent;

[0031] After mixing evenly, add slip agent, wax emulsion, wetting agent and defoamer, stir at 1100-1300 rpm, pass through a 250-mesh filter screen, and obtain a water-based varnish composition for UV offset printing.

Embodiment 2

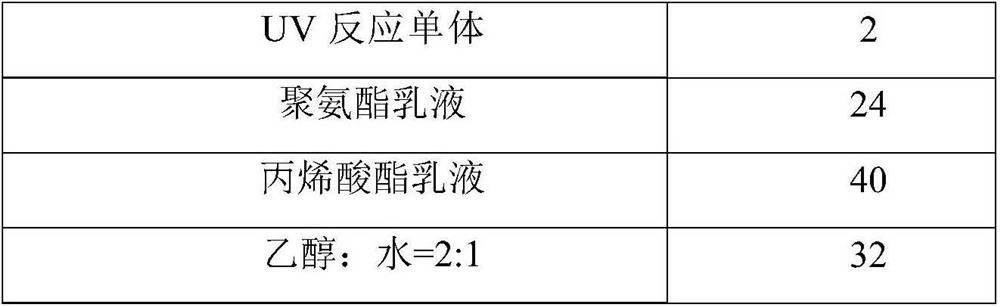

[0033] Table 2

[0034]

[0035]

[0036] The formula of the water-based varnish composition for UV offset printing of this embodiment is shown in Table 2, and the preparation method is the same as that of Example 1.

Embodiment 3

[0038] table 3

[0039] UV reactive monomer 3 polyurethane emulsion 28.5 Acrylic Emulsion 34 Ethanol: water = 2:1 32.5 slip agent 0.1 wax emulsion 2 D 0.1 Defoamer 0.1

[0040] The formula of the water-based varnish composition for UV offset printing of this embodiment is shown in Table 3, and the preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com