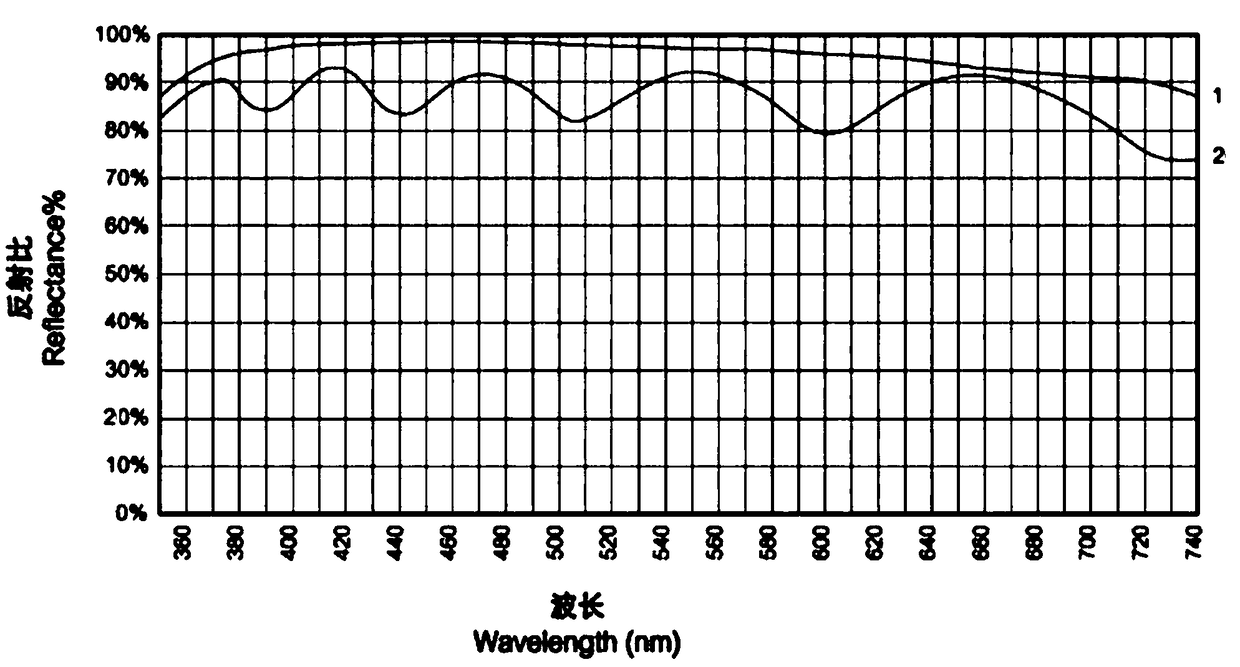

High diffuse reflection aluminum film on frosted surface and preparation method thereof

A technology with high diffuse reflection and frosted surface, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of low reflectivity of high reflective film and high reflectivity of high diffuse reflective aluminum film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a high diffuse reflection aluminum film on a frosted surface, comprising the steps of:

[0042] 1) Clean the frosted surface of the sandblasted aluminum plate to obtain a frosted surface that meets the requirements; the specific steps are as follows:

[0043]First use eight slots to ultrasonically clean the frosted surface of the sandblasting aluminum plate: the first slot is for degreasing, ultrasonic power: 1200W, ultrasonic frequency: 40KHz, temperature: 50°C; the second slot is for water rinsing, the water temperature is 50°C; the third slot and The fourth tank is pure water washing, ultrasonic power: 1200W, ultrasonic frequency: 40KHz, temperature: 50°C; the fifth and sixth tanks are pure water washing, ultrasonic power: 900W, ultrasonic frequency: 80KHz, temperature: 50°C; The seventh tank is to cut water and dry slowly, using a purification blower; the eighth tank is a drying tank, using a quartz tube heater.

[0044] Then dehydrate and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com