High-wear-resisting and energy-saving thin film for navigation airplane porthole glass and preparation method thereof

A technology for porthole glass and energy-saving film is applied in the field of high wear-resistant energy-saving film and its preparation, which can solve the problems that the outer surface of the glass is not subjected to high wear resistance, upgrade, and the energy-saving film system is not comprehensively used, so as to improve the flight comfort. , Good transmittance, high infrared reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

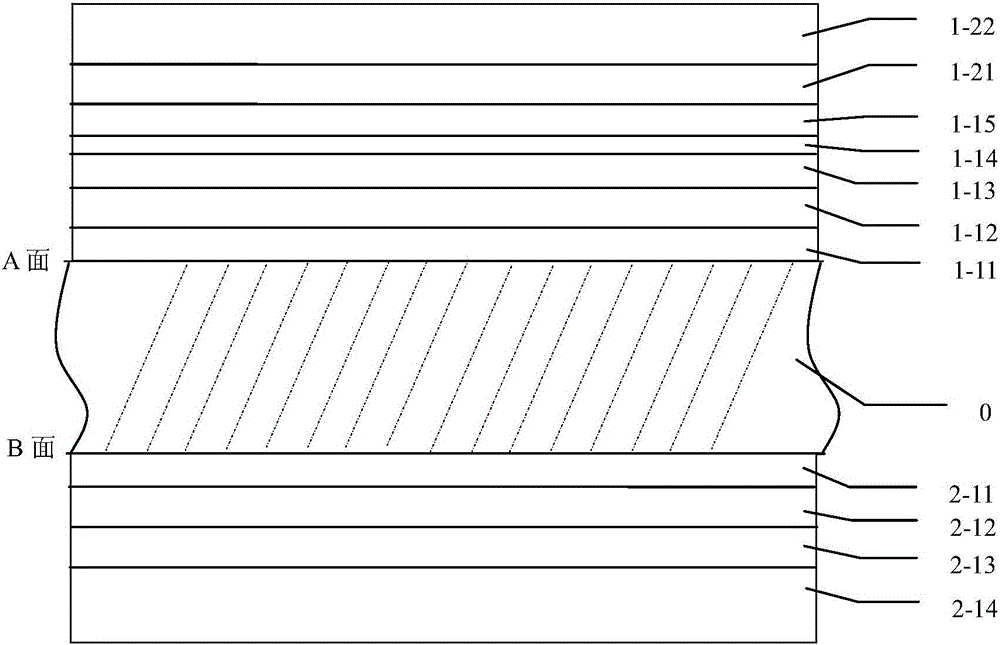

[0029] A high wear-resistant and energy-saving film for porthole glass of general aviation aircraft according to the present invention, said high wear-resistant and energy-saving film for porthole glass of general aviation aircraft comprises a plexiglass substrate 0, and said plexiglass substrate 0 is provided with an A surface and a B surface The A and B surfaces are respectively provided with different transparent films, the A surface is an energy-saving film system, and the B surface is a high-wear-resistant transparent film system; the energy-saving film system consists of a plexiglass substrate from the inside to the outside. Functional and protective layers. The high wear-resistant film is sequentially deposited from the inside to the outside of the organic glass substrate.

[0030] The inner side of the porthole is A, the outer side is B facing the outer side of the porthole, and the energy-saving functional layers are the first silicon oxide layer 1-11, the first zinc ...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is:

[0042] A high wear-resistant and energy-saving film for the porthole glass of general aviation aircraft of the present invention, the film thickness of the first silicon oxide layer 1-11 is 28nm, and the film thickness of the first zinc gallium oxide layer 1-12 is 25nm , the film thickness of the second zinc gallium indium oxide layer 1-13 is 30nm, the metal layer 1-14 is a metal silver layer, the film thickness of the metal silver layer is 8nm, the film of the second zinc gallium indium oxide layer 1-15 The layer thickness is 35nm;

[0043] The protective layer is sequentially composed of a second zinc gallium oxide layer 1-21 and a second silicon oxide layer 1-22 from the inside to the outside, the film thickness of the second zinc gallium oxide layer 1-21 is 35nm, and the second silicon oxide layer 1-21 is The film thickness of layers 1-22 is 95nm;

[0044] The film thickness of the first silicon nitride la...

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is: a kind of high wear-resisting and energy-saving film for the porthole glass of general aviation aircraft of the present invention, the film thickness of the first silicon oxide layer 1-11 is 20nm, the first zinc oxide layer The film thickness of the gallium layer 1-12 is 18nm, the film thickness of the second zinc gallium indium oxide layer 1-13 is 22nm, the metal layer 1-14 is a metal gold layer, and the film thickness of the metal gold layer is 10nm. The film thickness of zinc gallium indium oxide layer 1-15 is 28nm;

[0053] The protective layer is sequentially composed of a second zinc gallium oxide layer 1-21 and a second silicon oxide layer 1-22 from the inside to the outside, the film thickness of the second zinc gallium oxide layer 1-21 is 30nm, and the second silicon oxide layer 1-21 is The film thickness of layers 1-22 is 45nm;

[0054] The film thickness of the first silicon nitride layer 2-11 is 18nm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com