Drum brake pad forming processing production line

A technology of forming processing and production line, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of easy deviation of grinding position, easy deviation of pressing position, easy deviation of drilling position, etc. Accuracy and processing efficiency, the effect of improving tableting precision and processing efficiency, and improving the uniformity of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

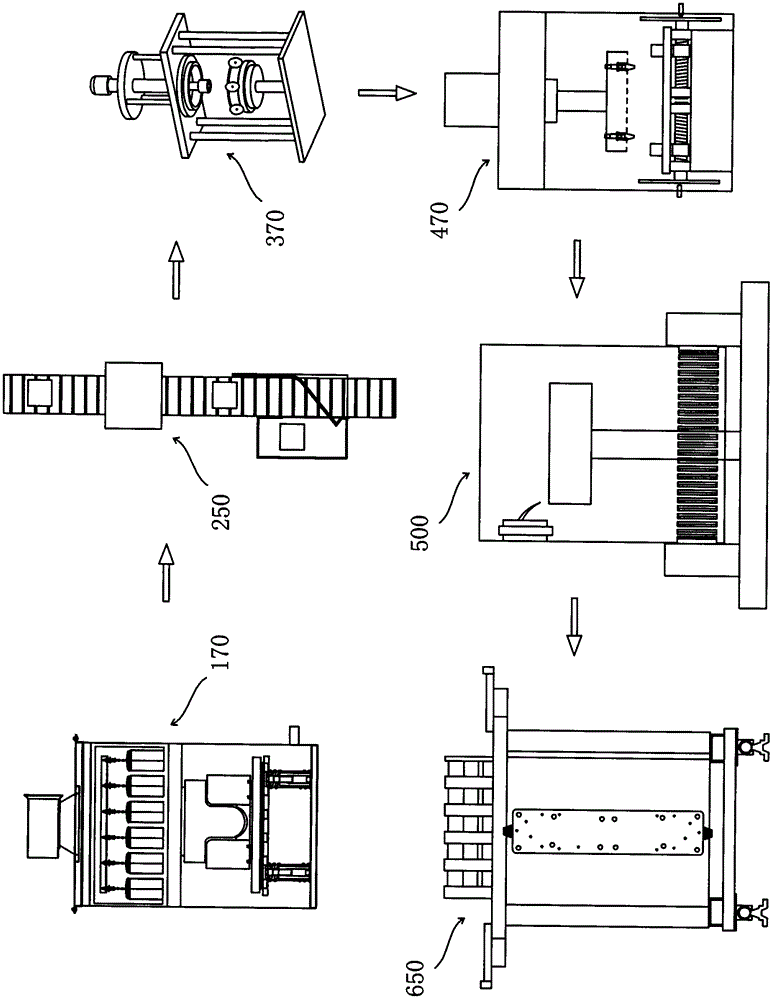

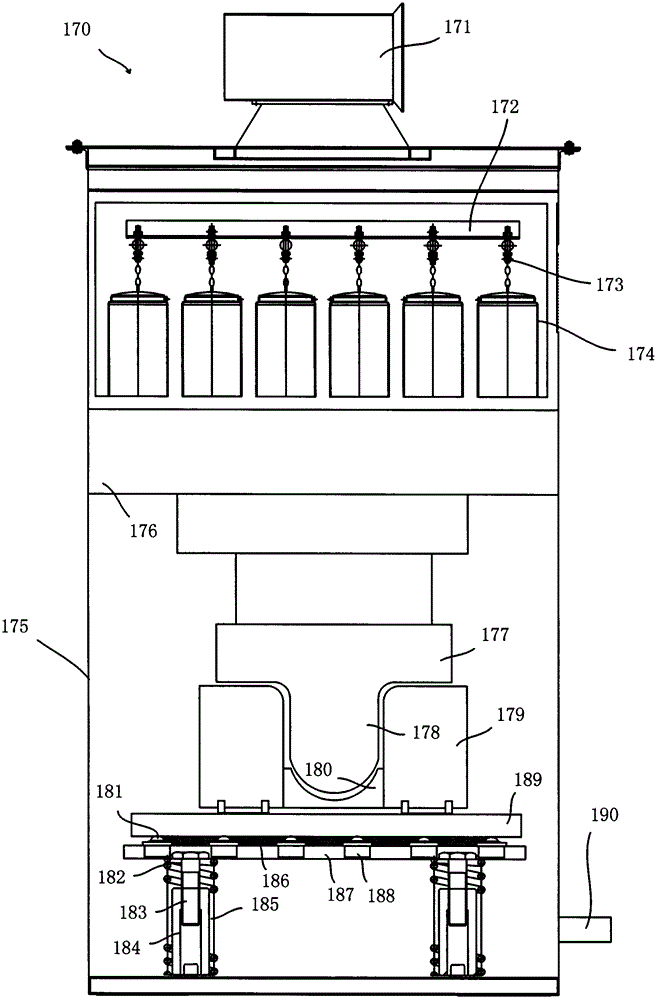

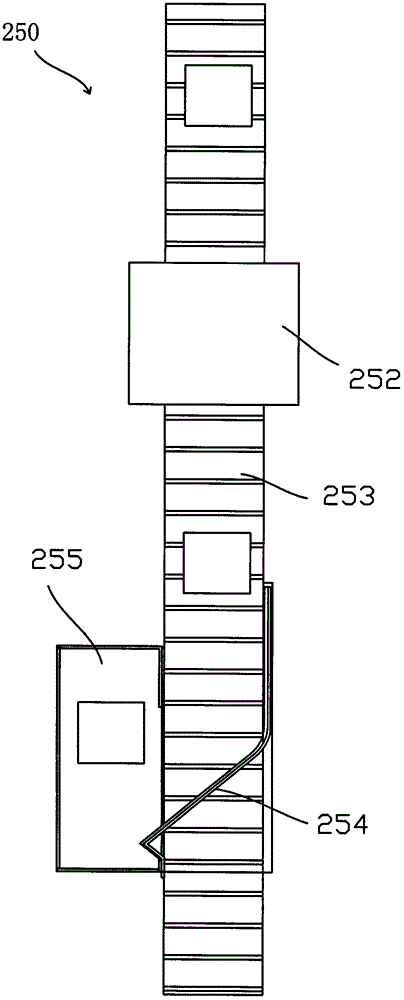

[0038] In order to further describe the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Figure 1-14 A production line for forming and processing drum brake pads shown includes a tablet pressing device 170, a heat treatment device 250, a grinding device 370, a drilling device 470, a gluing device 500, a drying device 650 and a conveying device connecting each device.

[0039] The tablet pressing device 170 includes a first frame 175 , the top of the first frame 175 is provided with an induced draft fan 171 , and the side of the bottom is provided with a pressure relief port 190 . The upper end of the first frame 175 is provided with a dust removal mechanism, which includes a fixed rod 172 placed on the top of the first frame 175, several dust removal bags 174 placed on the lower part of the fixed rod 172, and a set of dust removal bags for connecting the fixed rod 172 and the dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com