Steel-wood combined pre-assembly and separation type hydraulic self-climbing frame

A steel-wood combined and separated technology, which is applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., can solve problems such as slow climbing speed and complex structure, and achieve labor-saving and climbing stability. Good, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

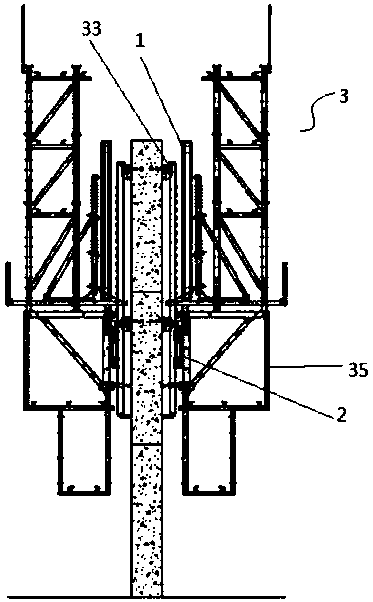

[0025] Such as Figure 1 to Figure 7 A steel-wood composite preassembled separate hydraulic self-climbing frame shown includes a formwork system 1 , a hydraulic climbing system 2 and a frame system 3 .

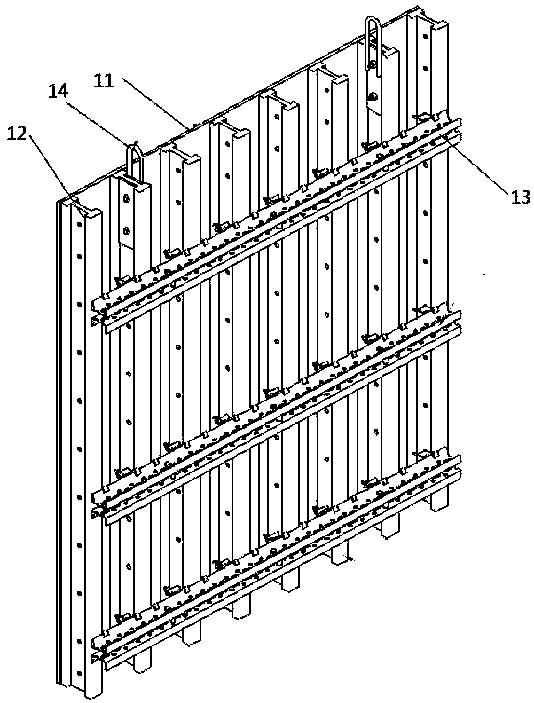

[0026] The formwork system 1 includes a panel 11, a vertical rib 12, a transverse rib 13 and a hook 14; the vertical rib 12 is a wooden I-beam and has several parallel arrangements; The same side of the vertical rib is perpendicular to the vertical rib 12 in the arrangement direction of the vertical rib and is connected by a connecting catch; the panel 11 is laid on the other side of the vertical rib 12;

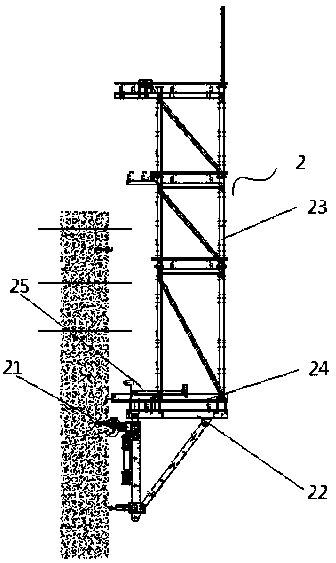

[0027] The frame system 2 includes a pre-embedded assembly 21, a load-bearing tripod 22 and a rearward moving truss 23; Vertically connected with the tripod pole 222; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com