Hollow cavity array with cavities having gradually-changed depths and in continuous distribution

A continuous, cavity technology, which is applied in the field of infrared temperature measurement, can solve the problems that the temperature measurement range is not wide enough, cannot be adjusted, and the working temperature range of the tape is narrow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

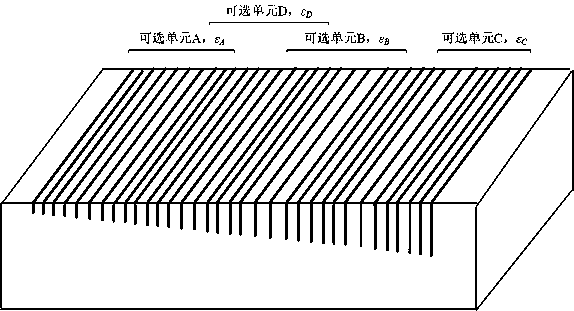

[0017] combine figure 1 , figure 2 and image 3 , the preparation steps of the cavity depth gradient continuous cavity array are as follows:

[0018] (1) Making a metal component as the base 1;

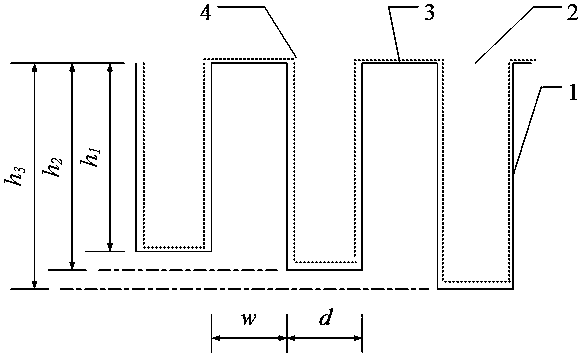

[0019] (2) Grooving is made on the upper surface of the metal member base 1, and a rectangular groove 2 with a specific depth and width ratio is formed by processing, and a rectangular fin 3 is simultaneously formed;

[0020] (3) The processing of the rectangular groove 2 adopts the fine wire electric discharge cutting technology;

[0021] (4) The width of the rectangular grooves 2 is the same and distributed uniformly and continuously, and the depth increases proportionally to form a continuous cavity array with gradually changing cavity depth;

[0022] (5) Perform surface treatment on the cavity array, and use electroplating technology to coat Cr to form a metal coating 4. The working surface formed by the coating presents emission and absorption isotropy, which is close to a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com