Inorganic high temperature resistant low infrared emissivity composite coating and preparation method thereof

A low-infrared emission, inorganic high temperature resistant technology, applied in chemical instruments and methods, layered products, metal layered products, etc. Improved temperature and high temperature stability, prevention of residual carbon contamination, ensuring low emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

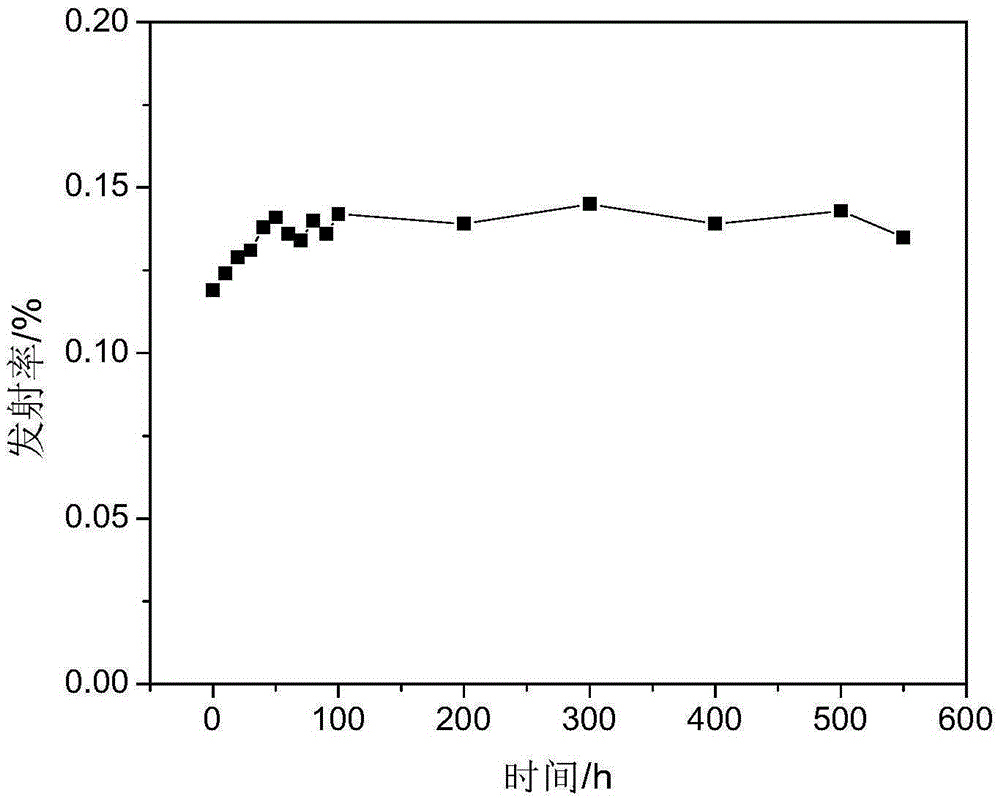

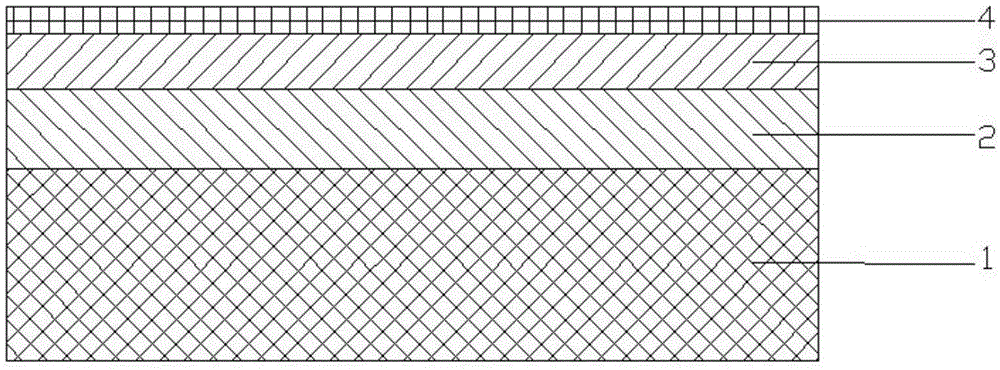

[0034] a kind of like figure 1 and figure 2 The inorganic high-temperature-resistant and low-infrared-emissivity composite coating shown is a multi-functional layer superposition structure, and the multi-functional layer superposition structure includes an oxidation barrier layer 2, a low-emission High-efficiency functional layer 3 and protective film 4, each layer is connected by mechanical bonding and chemical bonding, wherein the oxidation barrier layer is ZnO-Al 2 o 3 -SiO 2 Glass ceramic thin film, low emissivity functional layer is Pt thin film, protective film is TiO 2 film. The inorganic high-temperature-resistant low-infrared emissivity composite coating of this embodiment is deposited on the base material 1 of the GH3030 high-temperature nickel-based alloy plate. In this embodiment, the thickness of the oxidation barrier layer 2 is 3.0 μm, the thickness of the low-emissivity functional layer 3 is 1.5 μm, and the thickness of the protective film 4 is 1.0 μm.

...

Embodiment 2

[0043] a kind of like figure 1 The inorganic high-temperature-resistant and low-infrared-emissivity composite coating shown is a multi-functional layer superposition structure, and the multi-functional layer superposition structure includes an oxidation barrier layer 2, a low-emission High-efficiency functional layer 3 and protective film 4, each layer is connected by mechanical bonding and chemical bonding, wherein the oxidation barrier layer is ZnO-Al 2 o 3 -SiO 2 Glass ceramic thin film, low emissivity functional layer is Pt thin film, protective film is TiO 2 film. The inorganic high-temperature-resistant low-infrared emissivity composite coating of this embodiment is deposited on the base material 1 of the Inconel600 high-temperature nickel-based alloy plate. In this embodiment, the thickness of the oxidation barrier layer 2 is 4.0 μm, the thickness of the low-emissivity functional layer 3 is 3.0 μm, and the thickness of the protective film 4 is 0.5 μm.

[0044] In t...

Embodiment 3

[0052] a kind of like figure 1The inorganic high-temperature-resistant and low-infrared-emissivity composite coating shown is a multi-functional layer superposition structure, and the multi-functional layer superposition structure includes an oxidation barrier layer 2, a low-emission High-efficiency functional layer 3 and protective film 4, each layer is connected by mechanical bonding and chemical bonding, wherein the oxidation barrier layer is ZnO-Al 2 o 3 -SiO 2 Glass ceramic thin film, low emissivity functional layer is Pt thin film, protective film is TiO 2 film. The inorganic high-temperature-resistant low-infrared emissivity composite coating of this embodiment is deposited on the base material 1 of the GH4169 high-temperature nickel-based alloy plate. In this embodiment, the thickness of the oxidation barrier layer 2 is 5.0 μm, the thickness of the low-emissivity functional layer 3 is 1.0 μm, and the thickness of the protective film 4 is 0.8 μm.

[0053] In the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com