Composite coating with high temperature resistance and oxidation resistance and low infrared emissivity and preparation method thereof

A low-infrared emission, composite coating technology, used in chemical instruments and methods, coatings, metal material coating processes, etc. Improved high temperature stability, prevention of residual carbon contamination, and low emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

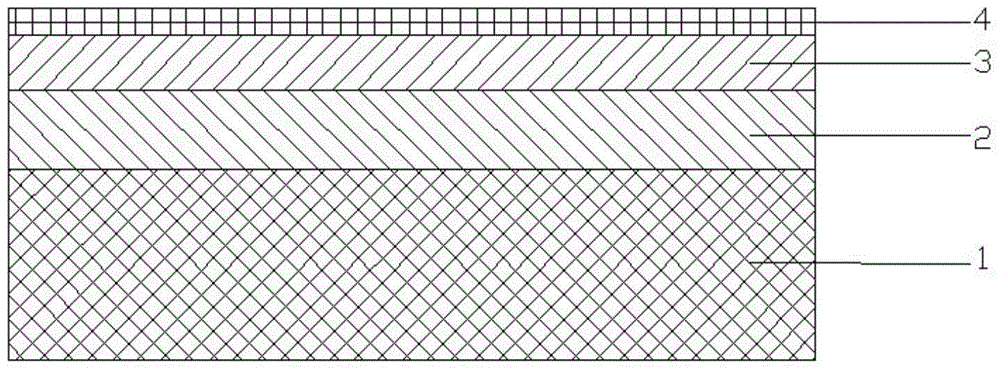

[0032] a kind of likefigure 1 , figure 2 The high-temperature-resistant and oxidation-resistant low-infrared-emissivity composite coating shown is a multi-functional layer superposition structure, which includes an oxidation barrier layer 2, a low-emissivity functional layer 3 and The protective film 4 is mainly bonded by mechanical bonding and solid phase diffusion connection between layers, wherein the oxidation barrier layer 2 is a NiCrAlY composite film, the low-emissivity functional layer 3 is a Pt film, and the protective film 4 is a MgO film.

[0033] The low infrared emissivity composite coating of this embodiment is deposited on the alloy substrate 1 of the GH3030 superalloy plate. In this embodiment, the thickness of the oxidation barrier layer 2 is 2.0 μm, the thickness of the low emissivity functional layer 3 is 2.0 μm, the thickness of the protective film 4 is 0.5 μm, and the oxidation barrier layer 2, the low emissivity functional layer 3 and the protection The...

Embodiment 2

[0041] a kind of like figure 1 The high-temperature-resistant and oxidation-resistant low-infrared-emissivity composite coating shown is a multi-functional layer superposition structure, which includes an oxidation barrier layer 2, a low-emissivity functional layer 3 and The protective film 4 is mainly bonded by mechanical bonding and solid phase diffusion connection between layers, wherein the oxidation barrier layer 2 is a NiCrAlY composite film, the low-emissivity functional layer 3 is a Pt film, and the protective film 4 is a MgO film.

[0042] The low infrared emissivity composite coating of this embodiment is deposited on the alloy substrate 1 of the Inconel 600 superalloy plate. In this embodiment, the thickness of the oxidation barrier layer 2 is 3.0 μm, the thickness of the low-emissivity functional layer 3 is 1.0 μm, the thickness of the protective film 4 is 1.0 μm, and the oxidation barrier layer 2, the low-emissivity functional layer 3 and the protection The films...

Embodiment 3

[0050] a kind of like figure 1 The high-temperature-resistant and oxidation-resistant low-infrared-emissivity composite coating shown is a multi-functional layer superposition structure, which includes an oxidation barrier layer 2, a low-emissivity functional layer 3 and The protective film 4 is mainly bonded by mechanical bonding and solid phase diffusion connection between layers, wherein the oxidation barrier layer 2 is a NiCrAlY composite film, the low-emissivity functional layer 3 is a Pt film, and the protective film 4 is a MgO film.

[0051] The low infrared emissivity composite coating of this embodiment is deposited on the alloy substrate 1 of the GH4169 superalloy plate. In this embodiment, the thickness of the oxidation barrier layer 2 is 4.0 μm, the thickness of the low-emissivity functional layer 3 is 1.5 μm, the thickness of the protective film 4 is 0.8 μm, and the oxidation barrier layer 2, the low-emissivity functional layer 3 and the protection The films 4 we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com