A Probe Temperature Sensing Black Body Cavity for Sapphire Optical Fiber Temperature Sensor

A technology of optical fiber temperature and blackbody cavity, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems affecting temperature measurement accuracy and long-term stability, surface degradation, etc., and achieve stable radiation signal and temperature relationship, The effect of stable overall performance and stable emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

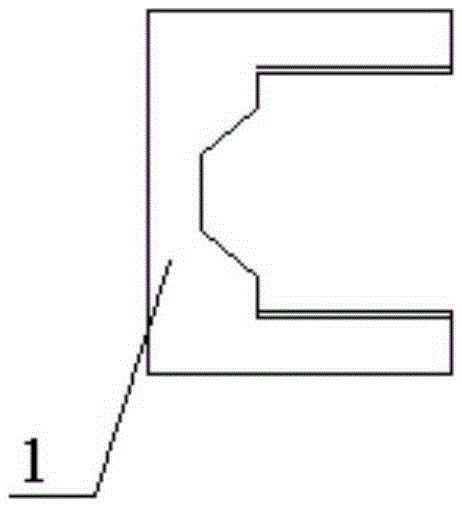

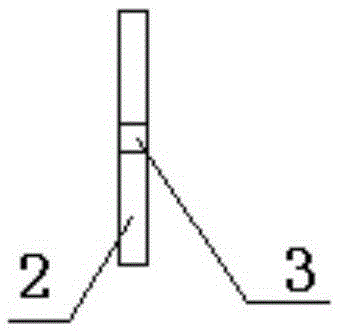

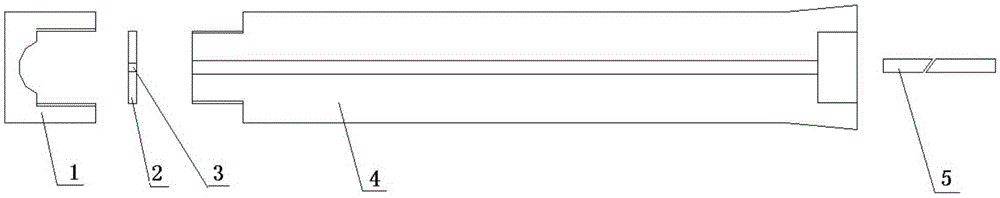

[0020] like figure 1 , figure 2 As shown, the internal structure of the temperature-sensitive blackbody cavity 1 adopts a box-type structure. The bottom of the temperature-sensitive blackbody cavity 1 is hemispherical, and the upper end is cylindrical. Internal threads are processed at the mouth of the temperature-sensitive blackbody cavity; Circular light shield 2 for radiation adjustment hole 3.

[0021] The core of the present invention is a structural design of a separate temperature-sensitive blackbody cavity. Due to the design of the structure, when the blackbody cavity is in contact with a high-temperature environment, its blackbody radiation performance is more stable than that of a general-structured blackbody cavity, so it can be used in the blackbody cavity When it is separated from the optical fiber, it can still obtain a stable corresponding relationship between the radiation intensity of the black body and the temperature, and then realize the contact measureme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com