Monitoring method for residual fatigue life of expansion joint bellows

A technology for fatigue life and expansion joints, applied in the field of expansion joints, can solve the problems of bellows' fatigue life impact, failure to provide early warning and alarm, etc., to facilitate on-site maintenance and repair, ensure safe operation, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

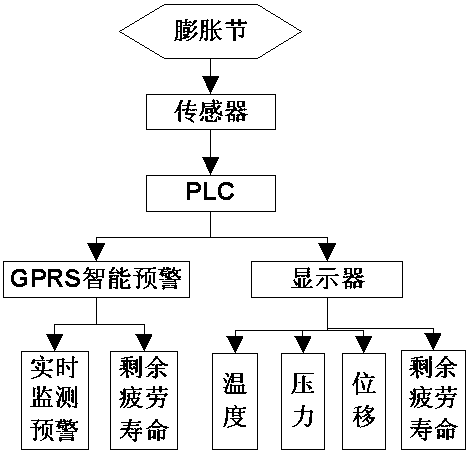

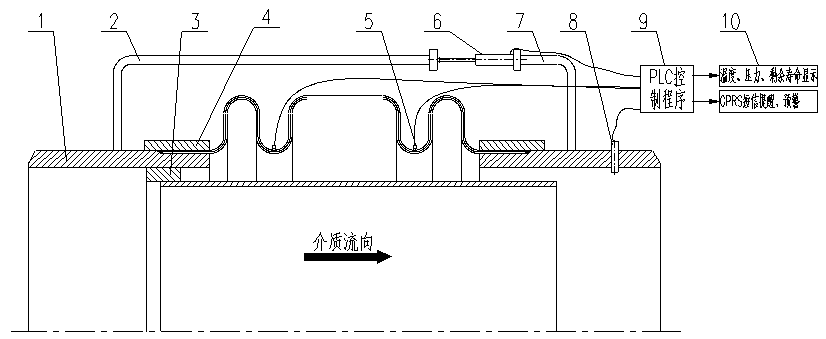

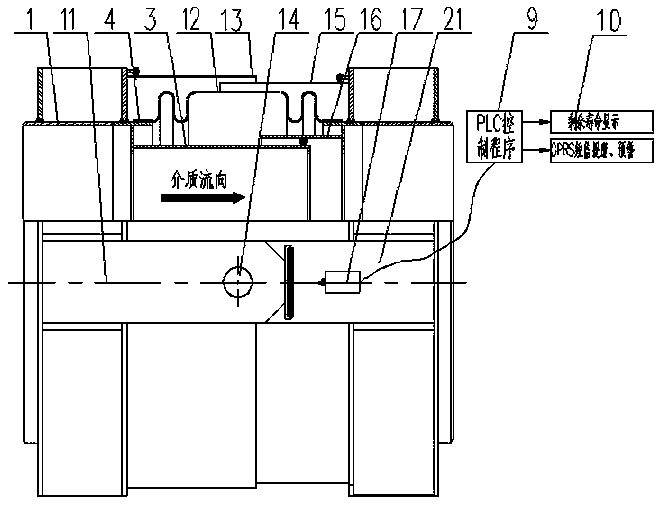

[0020] Such as figure 1 As shown, a method for monitoring the remaining fatigue life of expansion joint bellows uses a sensor to measure the displacement of the expansion joint bellows in real time under working conditions, and transmits the displacement to the PLC. The w fatigue life of the inner bellows [N cw ], where w=1, 2, 3..., by Get the remaining fatigue life N of bellows rf , where [N c ] is the design fatigue life of the bellows, the PLC displays the remaining fatigue life value, and gives an early warning and alarm when the remaining fatigue life reaches the set alarm value.

[0021] The displacements mentioned are lateral displacements, angular displacements, axial displacements or torsional displacements, and various displacements are measured by their corresponding displacement sensors installed on the expansion joints.

[0022] Such as figure 2 , 4 As shown, the internal pressure axial type expansion joint and the external pressure type expansion joint b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com