Five-axis five-linkage numerical control system capable of realizing switching of three-axis to five-axis modes and numerically-controlled machine tool

A technology for switching modes, CNC machine tools, applied in general control systems, control/regulation systems, digital control, etc., can solve the problems of small parts quantity, large equipment investment, high price, reduce noise, stable assembly accuracy, and increase slow down effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

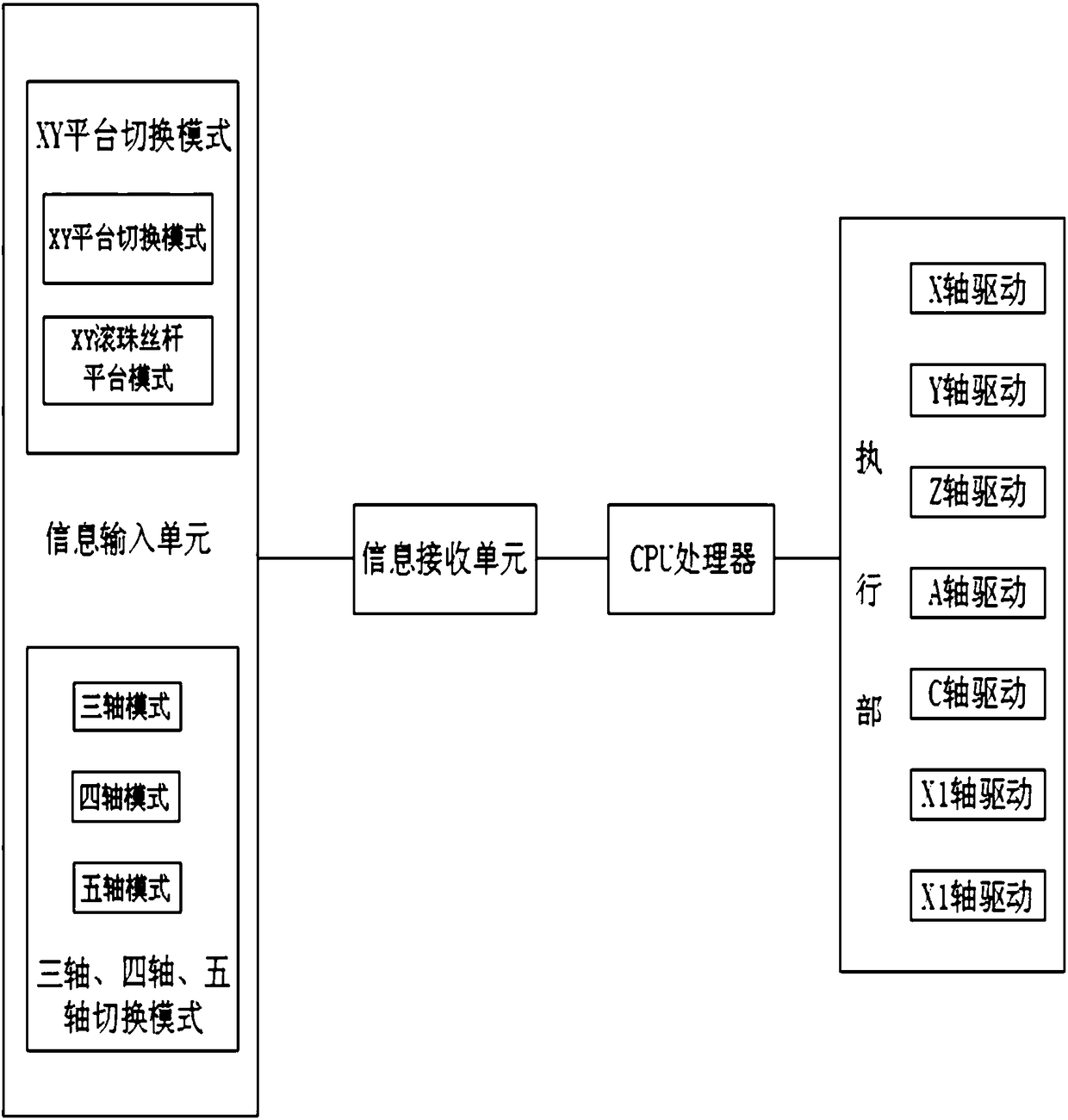

[0031] The five-axis and five-linkage CNC system introduced in this embodiment, which can switch between three and five-axis modes, is an expansion made on the basis of the five-axis and five-linkage CNC system in the prior art. It includes an information input unit, an information receiving unit unit, CPU processing unit, execution unit, and lock unit.

[0032] The information input unit is used for the input of numerical control mode information. CNC mode includes XY platform switching mode and three-axis, four-axis, five-axis switching mode that can be switched at the same time. XY platform switching mode includes XY ball screw platform mode and XY linear slide rail platform mode; three-axis, four-axis and five-axis switching modes include three-axis mode, four-axis mode and five-axis mode.

[0033] The information receiving unit receives information from the information input unit, and transmits the information to the CPU processor.

[0034] The CPU processor analyzes an...

Embodiment 2

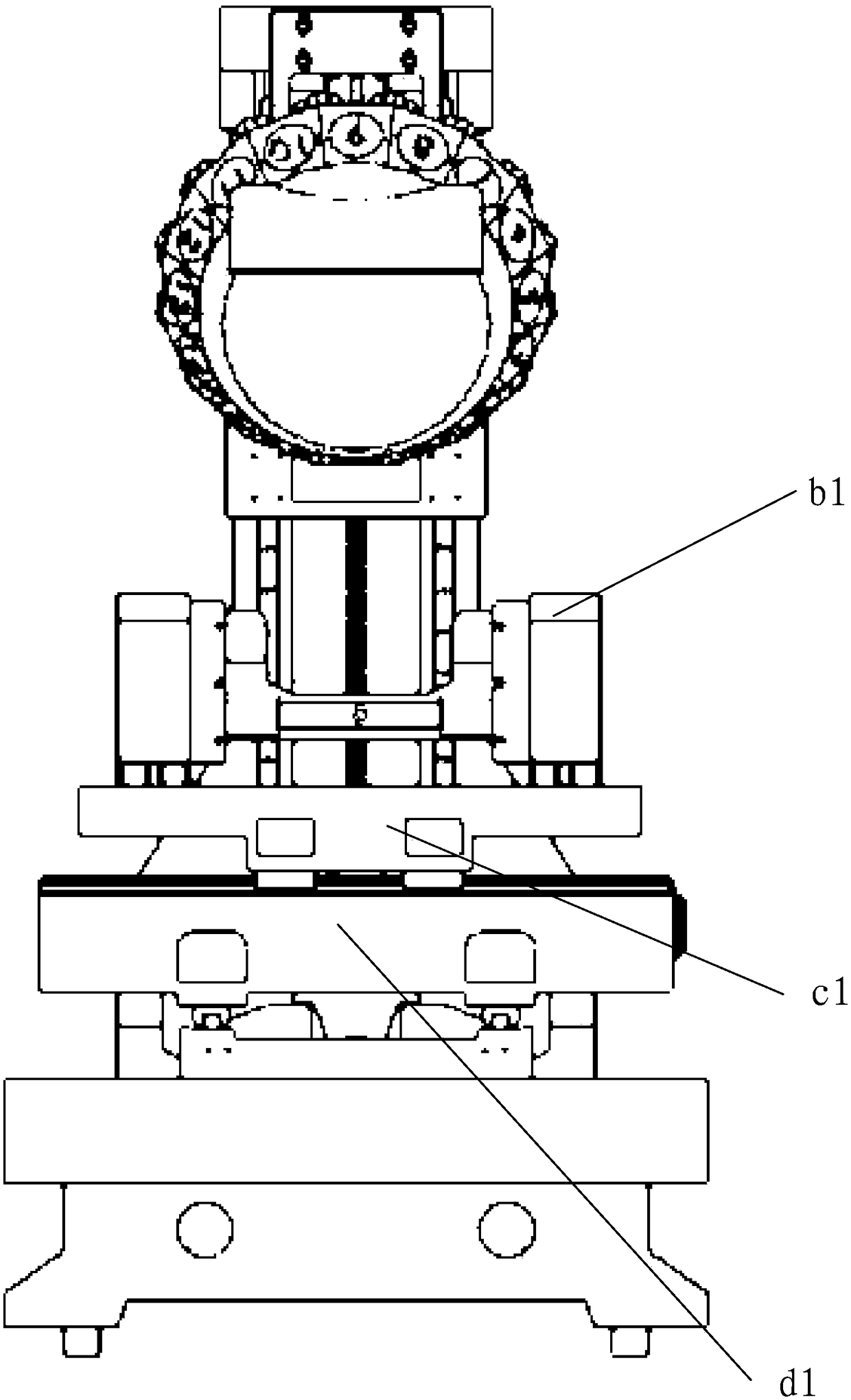

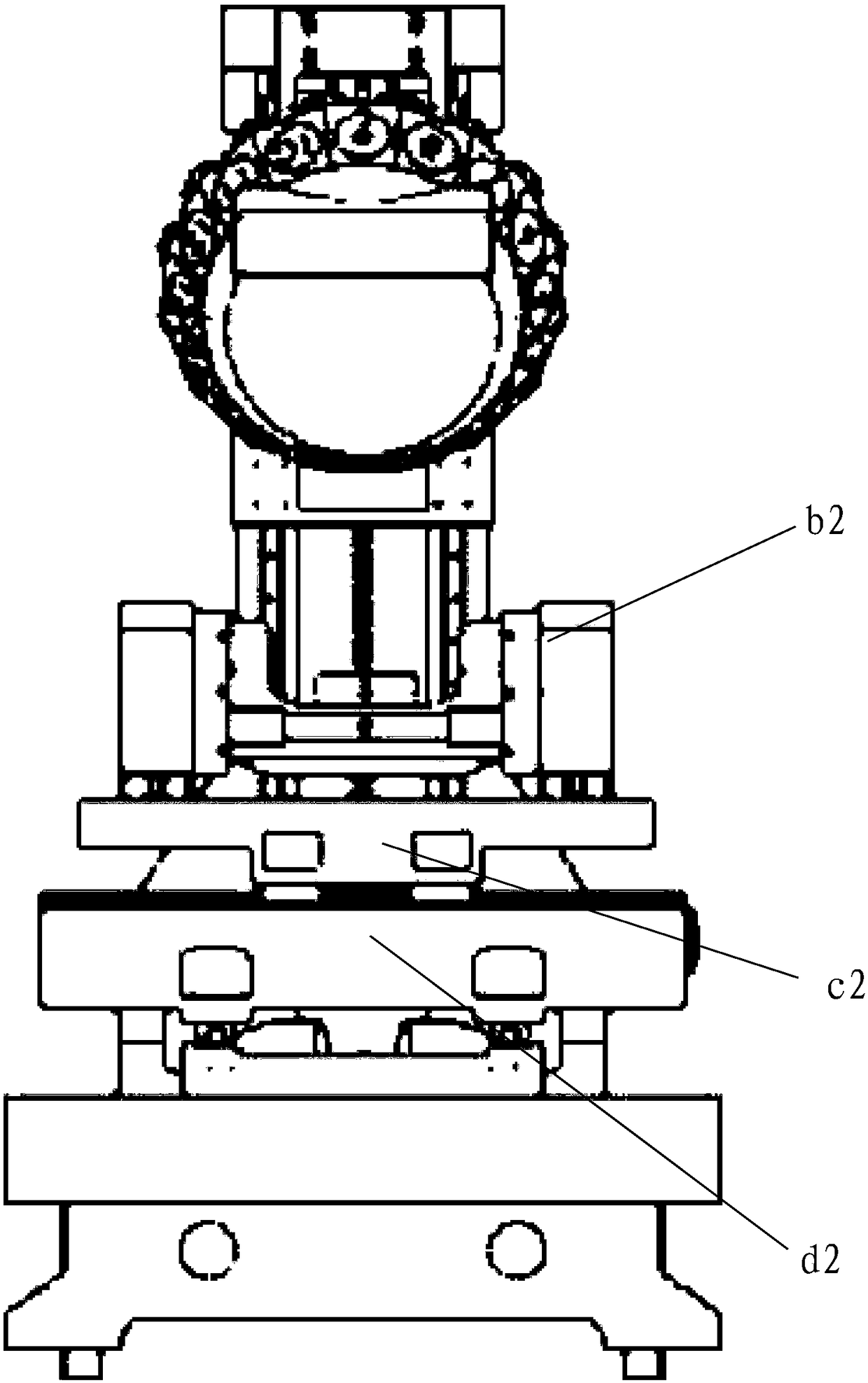

[0041] In this embodiment, a numerically controlled machine tool adopting the numerically controlled system in Embodiment 1 will be introduced.

[0042] The bed structure of the machine tool adopts the bed structure of a three-axis CNC machining center, and the column of the bed extends upwards by at least 200mm to create more installation space. The column is equipped with a tool magazine and a built-in electric spindle. An installation platform is installed on the XY ball screw platform under the electric spindle. The installation platform is used to install a four-axis turntable module, a five-axis turntable module or an XY linear motor. Platform: There is an interface for connecting the four-axis turntable module and the five-axis turntable module inside the machine tool, and there is also an interface for the XY linear motor platform.

[0043] The above CNC machine tool can realize the following functions by switching the CNC mode in the CNC system:

[0044] The first on...

Embodiment 3

[0051] This embodiment mainly describes the application of the CNC machine tool in the second embodiment.

[0052] If a speed increaser is installed on the electric spindle to double the speed of the spindle, coupled with the XY linear motor platform, the CNC machine tool can complete the processing and grinding of glass and ceramics.

[0053] On the basis of the above, a frozen plate-type stress-free fixing fixture (application number "201610986814.6") is installed on the XY linear motor platform, so that the CNC machine tool can process objects of any shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com