A Forward Closed-loop Manufacturing Method for Components

A component and closed-loop technology, applied in the field of forward closed-loop manufacturing of components, can solve problems such as restricting development, and achieve the effect of prolonging life cycle, improving enthusiasm, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

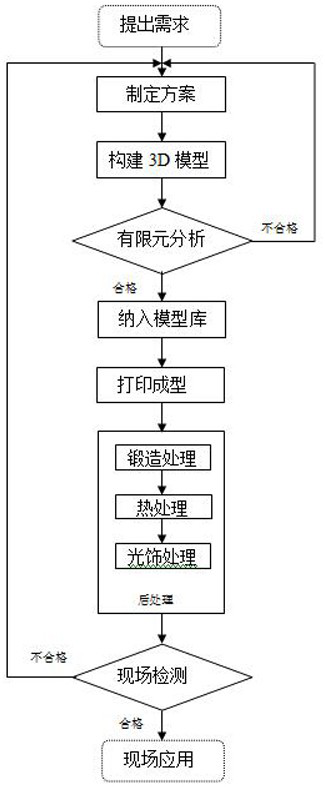

[0039] A method of forward closed-loop manufacturing of components, such as figure 1 shown, including the following steps:

[0040] 1. A method for manufacturing parts in a forward closed loop, characterized in that it comprises the following steps:

[0041] S1: The maintenance work site puts forward the demand for manufacturing parts;

[0042] In the operation and maintenance of electrical equipment, parts of different brands, models, and batches of electrical equipment are involved; at the same time, maintenance personnel are constantly in contact with new equipment in production work, so there is a need to improve work tools and upgrades. Equipment performance needs to improve production efficiency. A large number of spare parts reserves will consume storage resources and waste funds, and failure to replace parts in time will cause equipment to "work with illness" and reduce the reliability of power supply. Therefore, when a certain component is required at the maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com