Steel template grinding machine

A steel formwork and grinding machine technology, which is applied in the direction of grinding frame, grinding machine parts, grinding machines, etc., can solve the problem that the bristles of the steel formwork are easy to wear, and achieve the effects of easy grinding, quick wetting, and slip prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

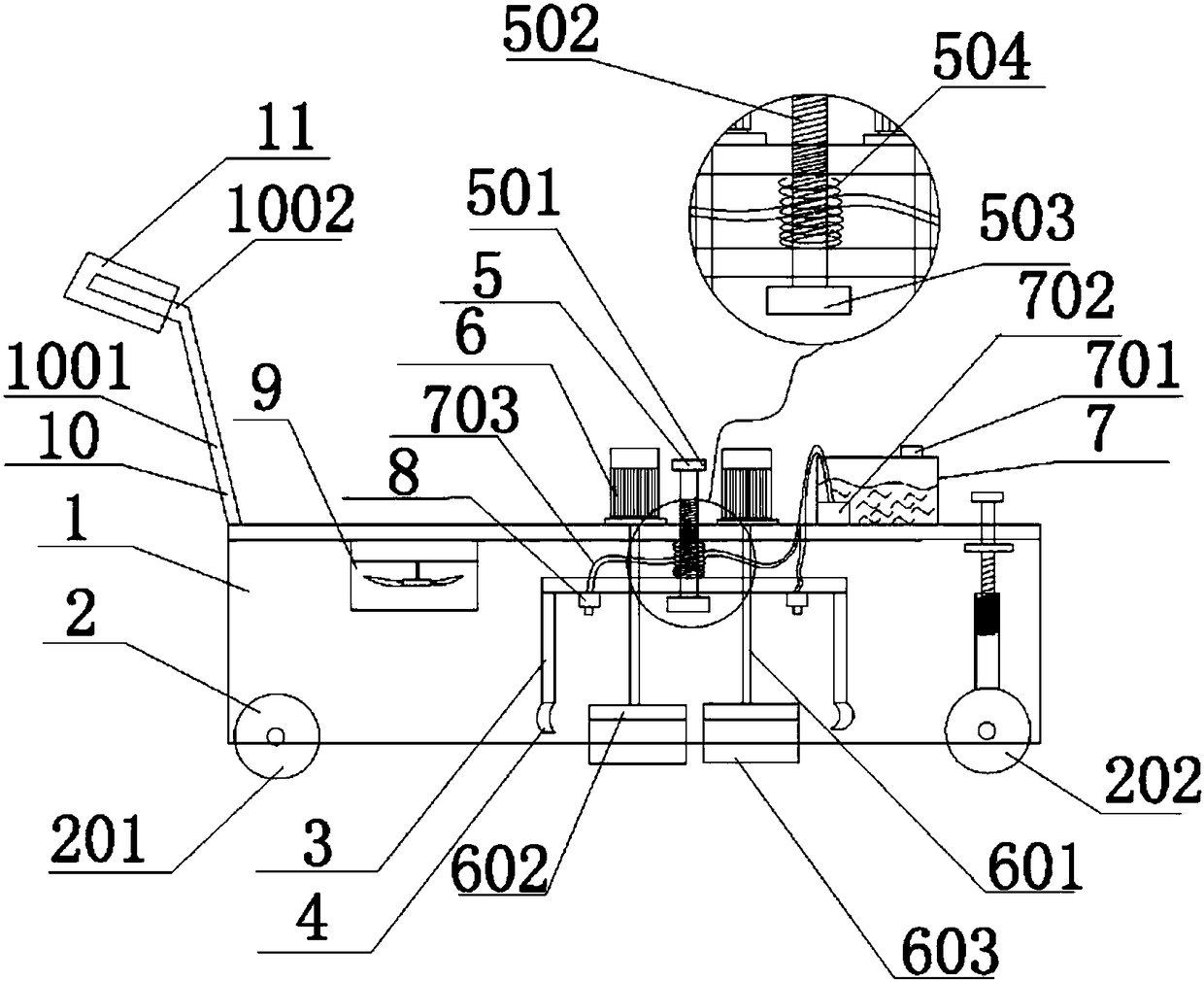

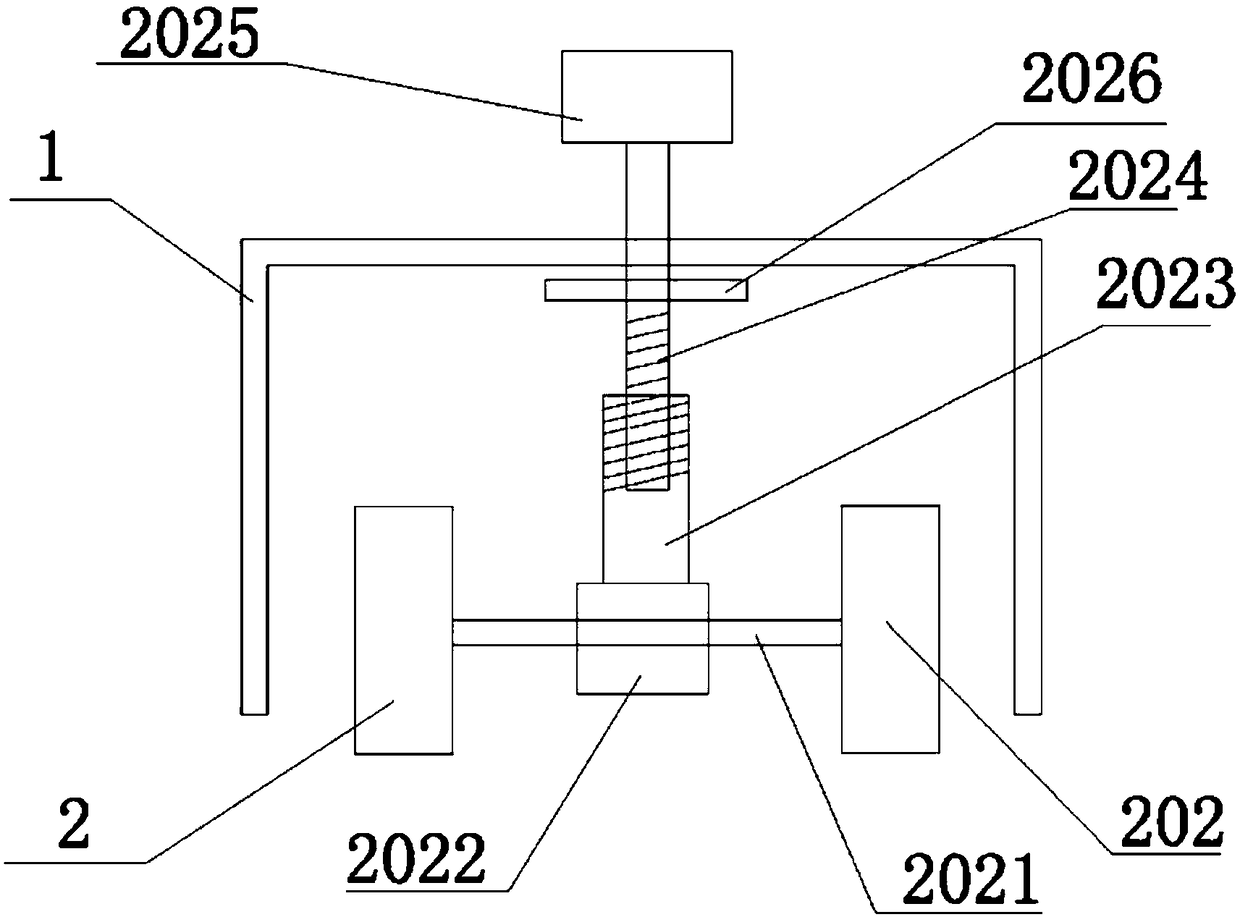

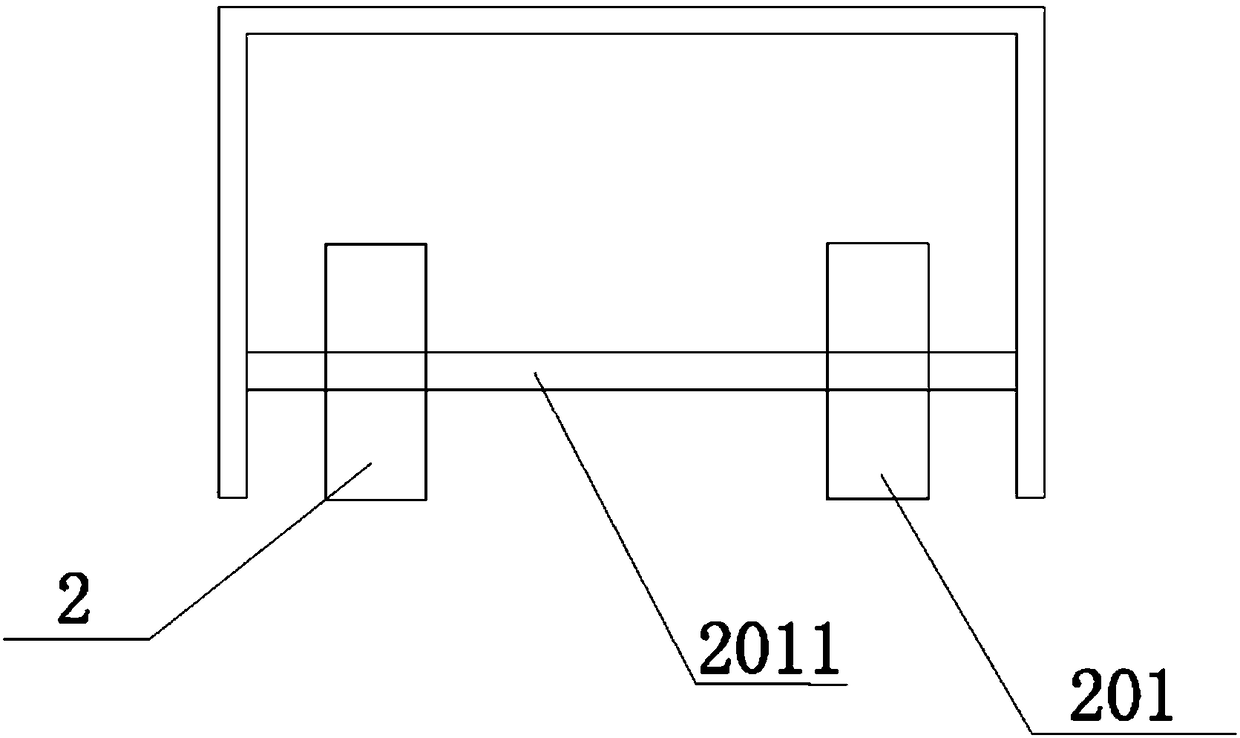

[0018] Such as Figure 1-4 As shown, a steel template grinding machine includes a car body 1, the car body 1 is a cavity with an opening on the lower side, four wheels 2 are connected to the bottom of the car body 1, and a water collecting cover 3 is arranged in the car body 1 , the water collecting cover 3 is a cavity opened below, the lower opening edge of the water collecting cover 3 is connected to the rubber ring 4, the upper plate of the vehicle body 1 and the upper plate of the water collecting cover 3 are connected by a connecting piece 5, and the connecting piece 5 includes the first A runner 501, the first runner 501 connects the connecting rod 502, the upper plate of the car body 1 and the upper plate of the water collecting cover 3 are provided with a through hole for the connecting rod 502 to pass, and the connecting rod 502 is provided with external threads, The upper plate through hole of the car body 1 is provided with an internal thread used in conjunction wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com