Nonskid chain and application method thereof

A technology of anti-skid chains and chains, applied in the field of anti-skid chains, can solve problems such as anti-skid chains bumping, scratching vehicle suspension, etc., to achieve the effects of improving firmness, enhancing safe driving, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

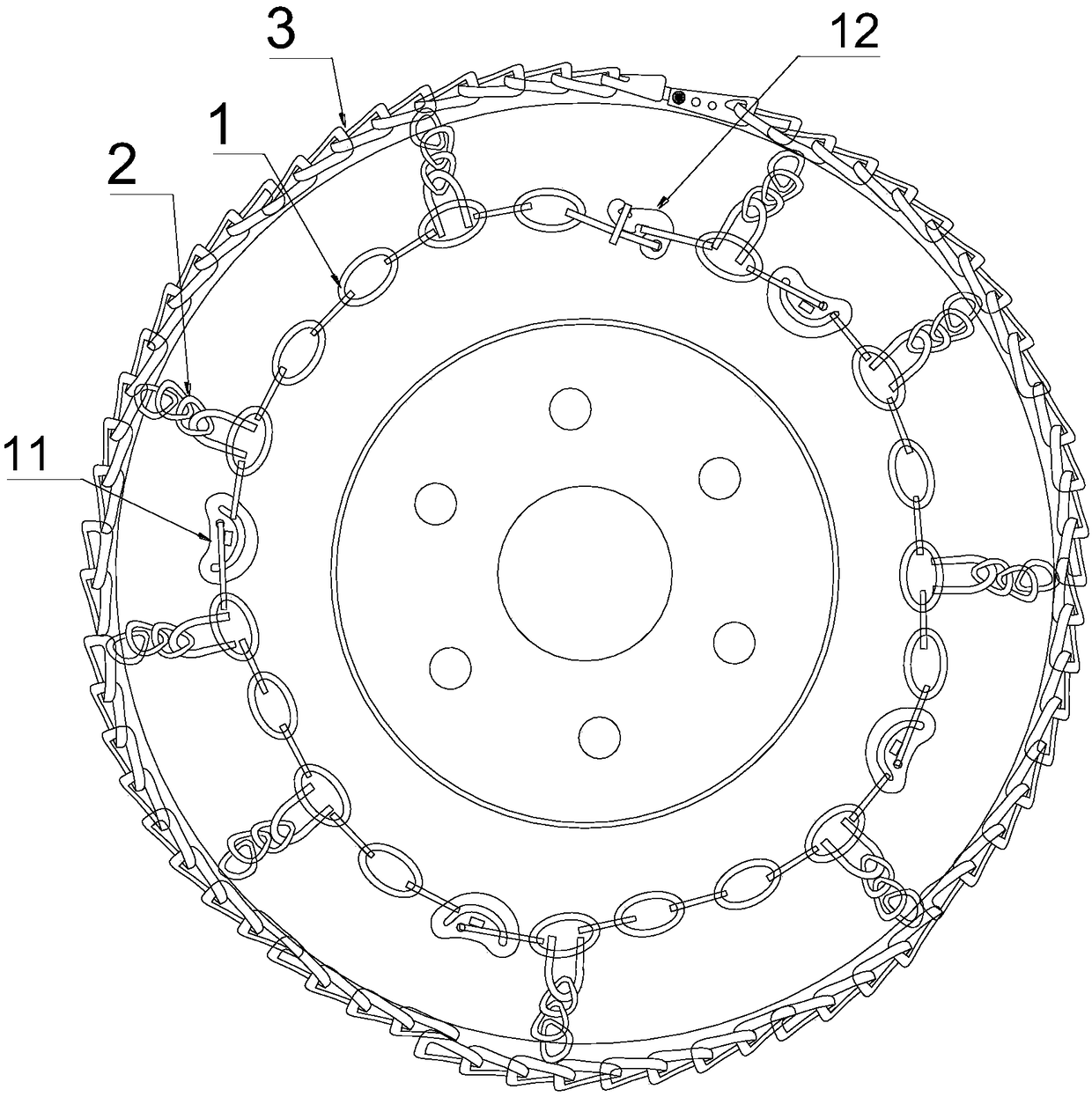

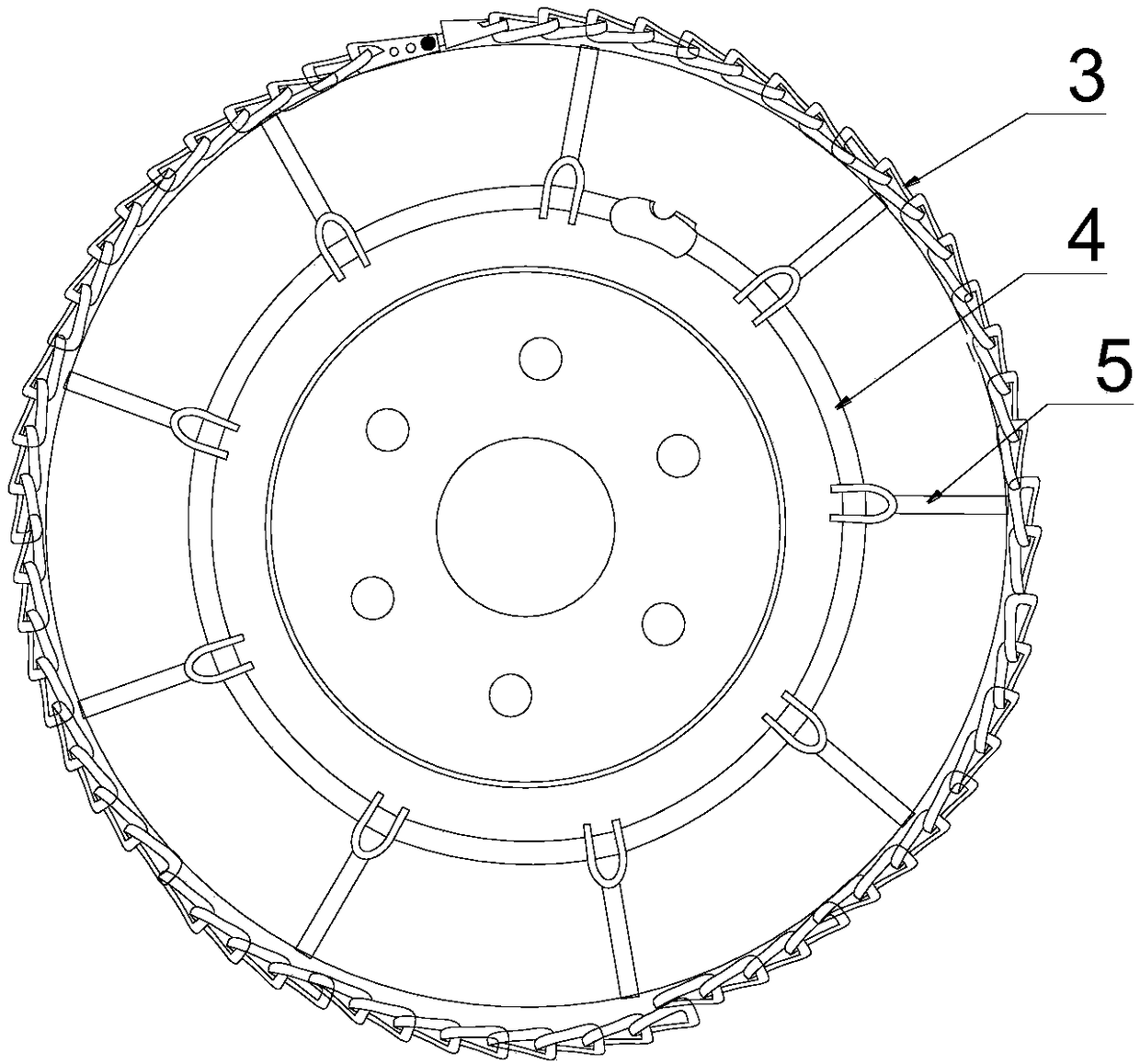

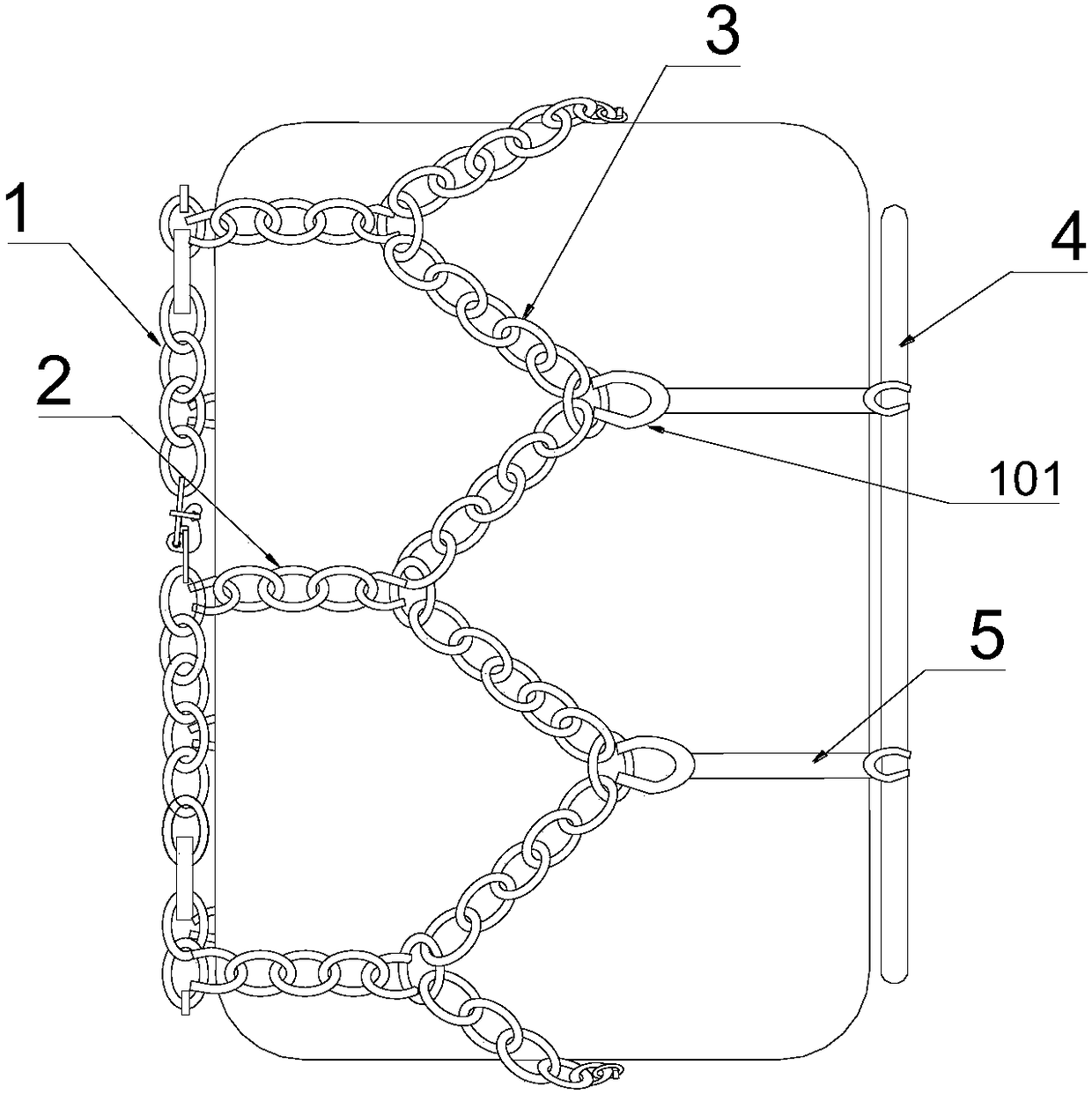

[0047] Such as figure 1 and figure 2 As shown, an anti-skid chain, the anti-skid chain includes a steel chain part and a steel rope part, the steel chain part includes a first chain 1, a plurality of second chains 2 and a third chain 3, and the steel rope part includes a first steel wire rope 4 and a plurality of second steel wire ropes 5, the first chain 1 includes a multi-section chain, and the multi-section chains are connected to each other by a plurality of fasteners 11 to form a strip chain, and the two ends of the second chain 2 are evenly spaced from the first chain 2 through the connectors. A chain 1 is connected with a third chain 3, and the two ends of a plurality of second steel wire ropes 5 are connected with the first steel wire rope 4 and the third chain 3 evenly at intervals through connectors respectively, and the first chain 1, the third chain 3 and the first The head and tail of the wire rope 4 are detachably connected along the tire through the connecting...

Embodiment 2

[0063] Such as Figure 15 and Figure 16 As shown, this embodiment is basically the same as Embodiment 1, except that the connector of the third chain 3 is a lock ring 35, and the lock ring 35 includes a hook body 351, a movable rod 352 and a nut 353, and the movable rod 352 and the lower end of the hook body 351 are hinged, and the top to the upper end of the movable rod 352 are all provided with threads, and the nut 353 is installed on the thread of the movable rod 352, and the upper ends of the hook body 351 and the movable rod 352 are all provided with mutually matching gaps 3501 , when in use, push the movable rod 352 inward and hang the chain rings at both ends of the third chain 3 in the hook body 351 respectively, align the hook body 351 with the notch 3501 of the movable rod 352, and turn the nut 353 to move upward along the thread Until the nut 353 is tightened at the notch 3501, the locking is completed.

Embodiment 3

[0065] Such as Figure 17 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the connecting piece between the second steel wire rope 5 and the first steel wire rope 4 is a "U"-shaped second connecting piece 51, and the "U"-shaped second connecting piece Both sides of the piece 51 are provided with a ninth through hole 511, the first steel wire rope 4 passes through the ninth through hole 511, and one end of the second steel wire rope 5 is welded to the "U"-shaped part of the "U"-shaped second connecting piece 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com