Forming member for controlling the volume of packs of pourable food products formed from a tube of packaging material

A technology for forming components and packaging materials, which is applied in the direction of packaging food, multiple packages, and types of packaging items, etc., can solve problems affecting packaging formation and other issues, and achieve the effect of avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

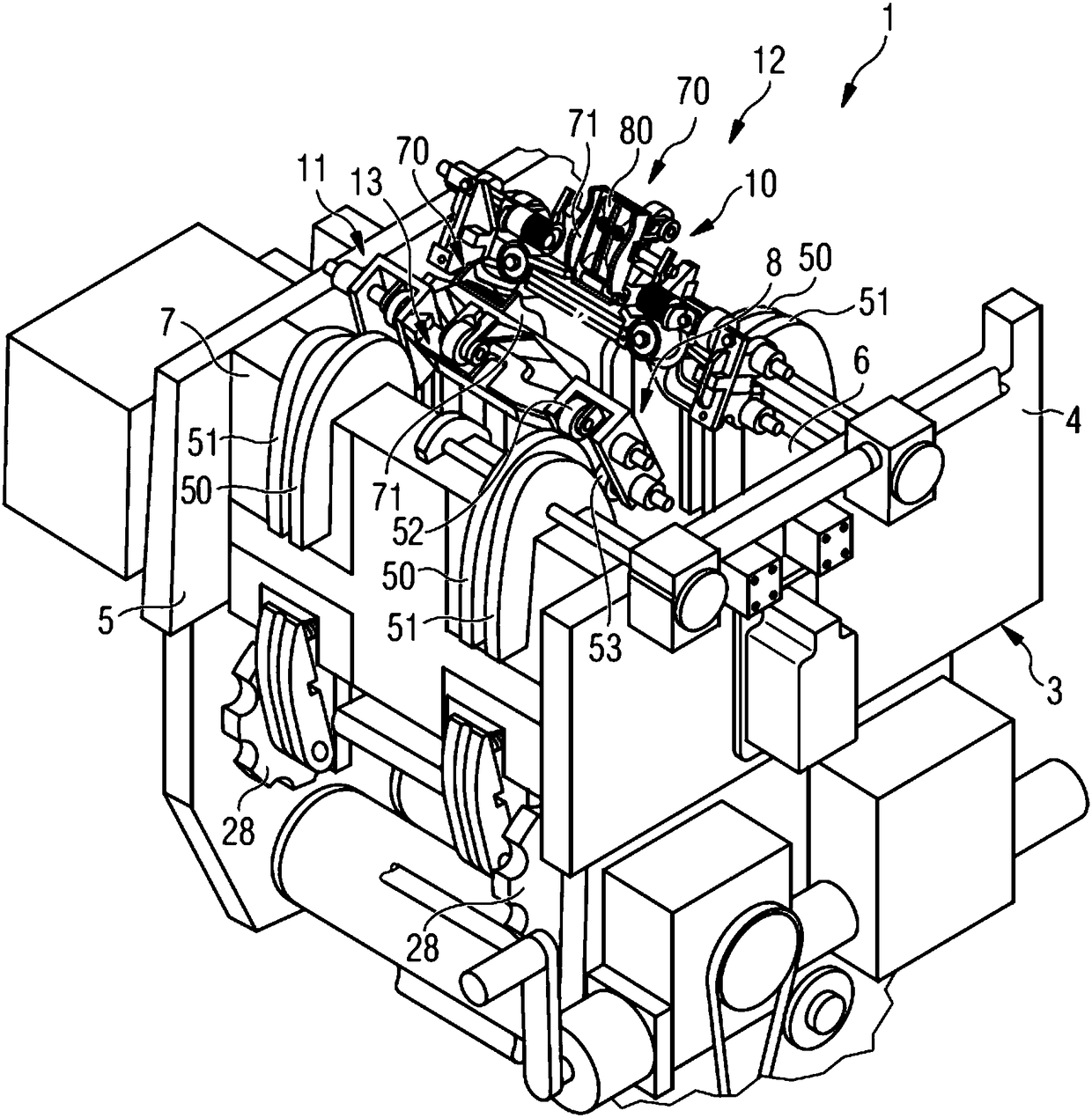

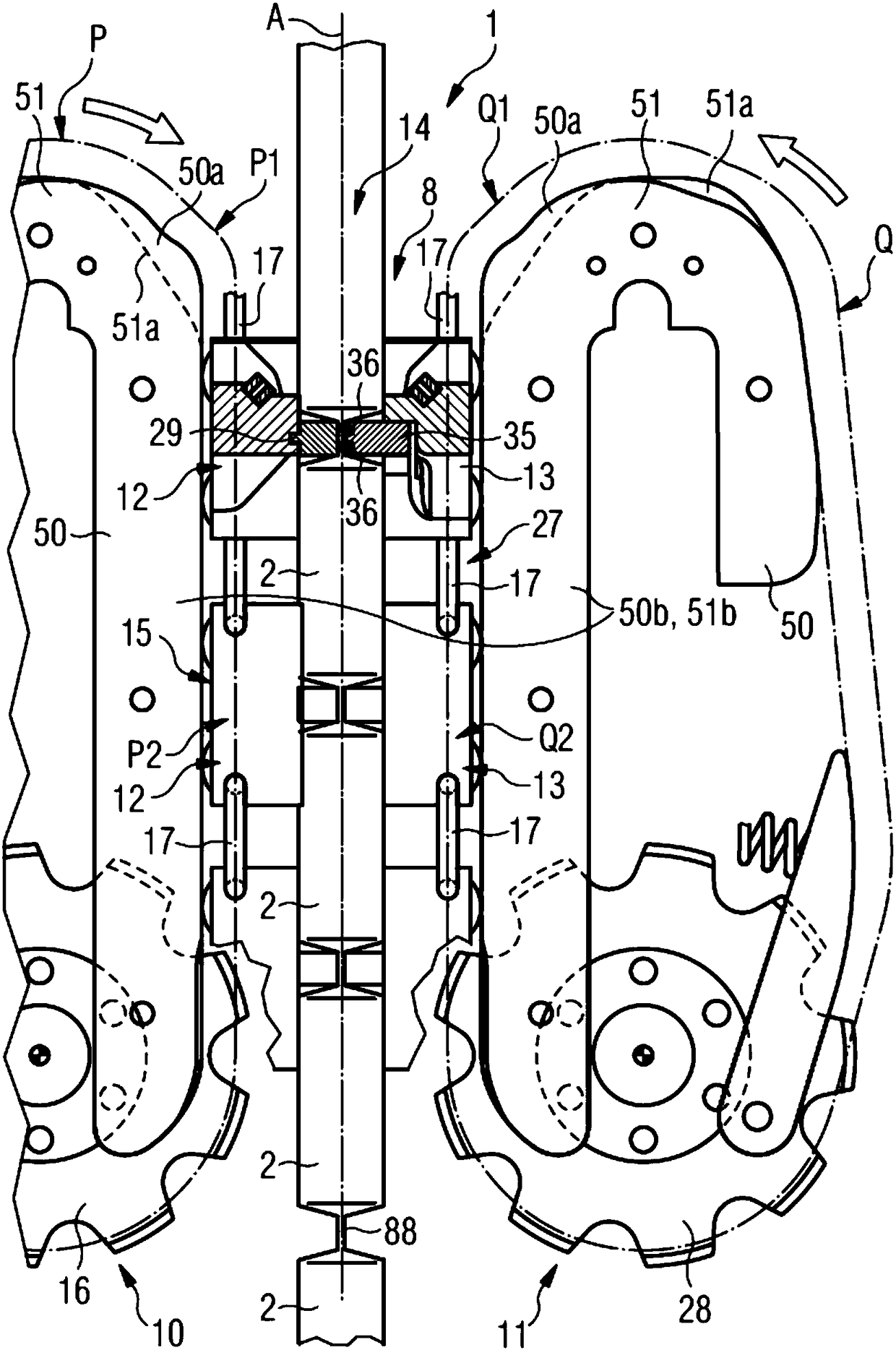

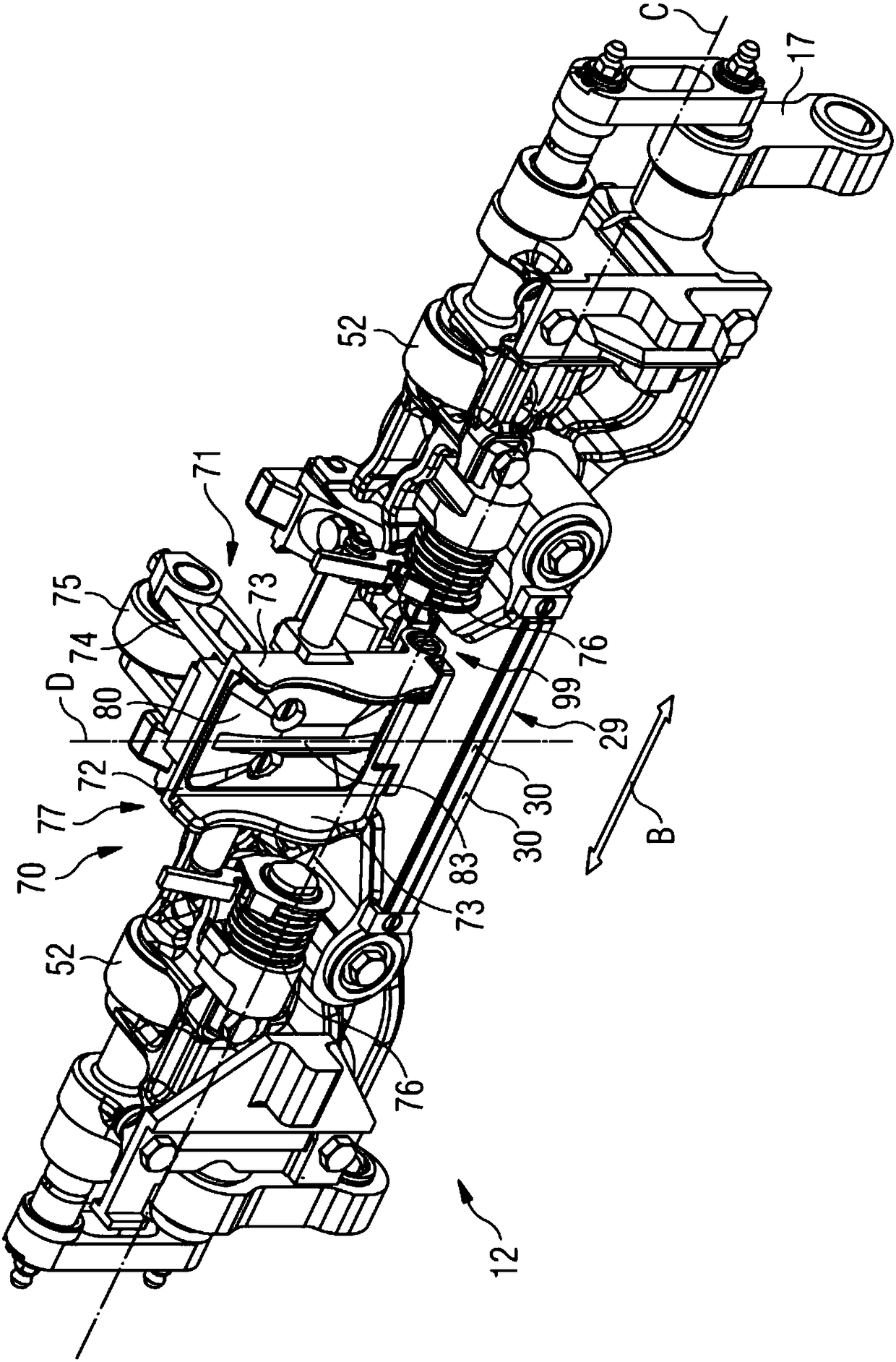

[0048] figure 1 and figure 2 Shown is a packaging machine 1 for producing sealed packages 2 containing pourable food products (eg pasteurized or UHT milk, fruit juice, wine etc.) from a tube 14 of packaging material.

[0049] The tube 14 has a longitudinal axis A and is formed in a known manner by longitudinally folding and sealing a web of packaging material and is filled upstream with sterilized or aseptically processed food product.

[0050] In particular, the tube 14 passes through the first longitudinal edge 100 of the packaging material ( Image 6 ) superimposed on the second longitudinal edge 101 of the packaging material ( Image 6 ) and by sealing the first longitudinal edge 100 to the second longitudinal edge 101 to obtain a longitudinal seal 102 by means of sealing means (not shown).

[0051] The packaging machine 1 comprises a frame 3 defined by a first side wall 4 and a second side wall 5 and a first transverse wall 6 and a second transverse wall 7 mounted rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com