Aromatic polyamide porous membrane, preparation method of the same and lithium ion secondary battery

A technology of aromatic polyamide and porous membrane, which is applied to battery components, circuits, electrical components, etc., and can solve problems such as very high temperature and humidity requirements, increased battery internal resistance, and long production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

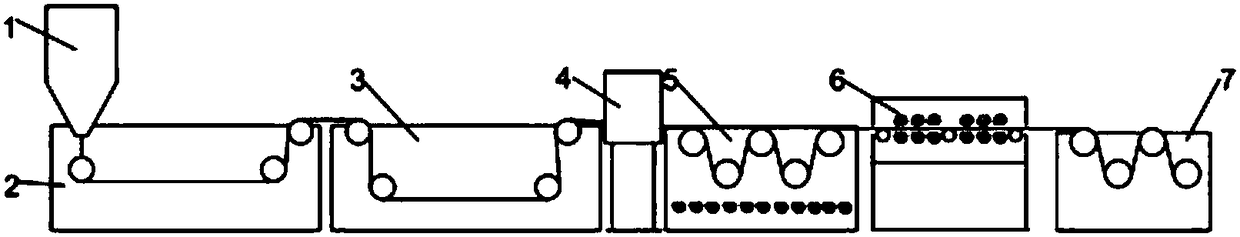

Method used

Image

Examples

Embodiment 1

[0038] A polym-phenylene isophthalamide solution (8000 g) was obtained through two-stage screw polymerization, and the solvent was DMAC, wherein the polymer mass percent concentration was 11.1%. Above-mentioned solution enters gel bath to form film after being extruded by melt pump after die head after degassing, and gel bath is water and DMAC, and the proportion of the quality of water in the gel bath is 30%, and gel bath temperature is At 30°C, the gel time was 100 seconds. Next, the above-mentioned membrane is drawn into an extraction tank, the temperature of which is 80° C., and the solvent is extracted with water, thereby forming a membrane to be treated with a dense skin and a porous interior. The above-mentioned film to be treated is removed with a brush, then dried with hot air at a drying temperature of 100°C, and finally enters a high-temperature calibrating box at a calibrating temperature of 250°C. Winding is completed after static electricity is removed. The mea...

Embodiment 2

[0040] A polyphenylsulfone terephthalamide solution (6000 g) was polymerized in a reaction kettle, and the solvent was DMAC, wherein the mass percent concentration of the polymer was 33%. Methyltriethylammonium acetate (120g) and the polyphenylsulfone terephthalamide solution prepared above were metered into a twin-screw machine at a mass ratio of 1:5 to mix and disperse. After being extruded from the die, it enters a gel bath to form a film, and the gel bath is water and DMAC. The mass proportion of water in the gel bath is 20%, the temperature of the gel bath is 0° C., and the gel time is 200 seconds. Next, the above-mentioned membrane is drawn into an extraction tank, the temperature of which is 20° C., and the solvent is extracted with water, thereby forming a membrane to be treated with a dense skin and a porous interior. The above-mentioned film to be treated is removed with a silica gel scraper, dried with hot air at a drying temperature of 100°C, and finally enters a ...

Embodiment 3

[0042] A polym-phenylene isophthalamide solution (4000 g) was obtained through two-stage screw polymerization, the solvent was DMAC, and the polymer mass percent concentration was 25%. PEG-400 (polyethylene glycol 400, 333g) and the above-prepared polym-phenylene isophthalamide solution were metered and injected into the twin-screw machine at a mass ratio of 1:10 to mix and disperse, and passed through the melt after defoaming After the pump is extruded by the die, it enters the gel bath to form the film, and the gel bath is water and DMAC. The mass proportion of water in the gel bath is 36%, the temperature of the gel bath is 15° C., and the gel time is 100 seconds. Next, the above-mentioned membrane is drawn into an extraction tank, the temperature of which is 80° C., and the solvent is extracted with water, thereby forming a membrane to be treated with a dense skin and a porous interior. The above-mentioned film to be treated is removed by a brush, dried with hot air at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com