Composite soil nailing wall and pile-anchor support compound support structure and construction method

A technology of composite soil nailing and composite support, which is applied in basic structure engineering, excavation, construction, etc., and can solve problems such as poor mechanical properties of backfill soil layers, small grading space, and influence of composite soil nailing on wall support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

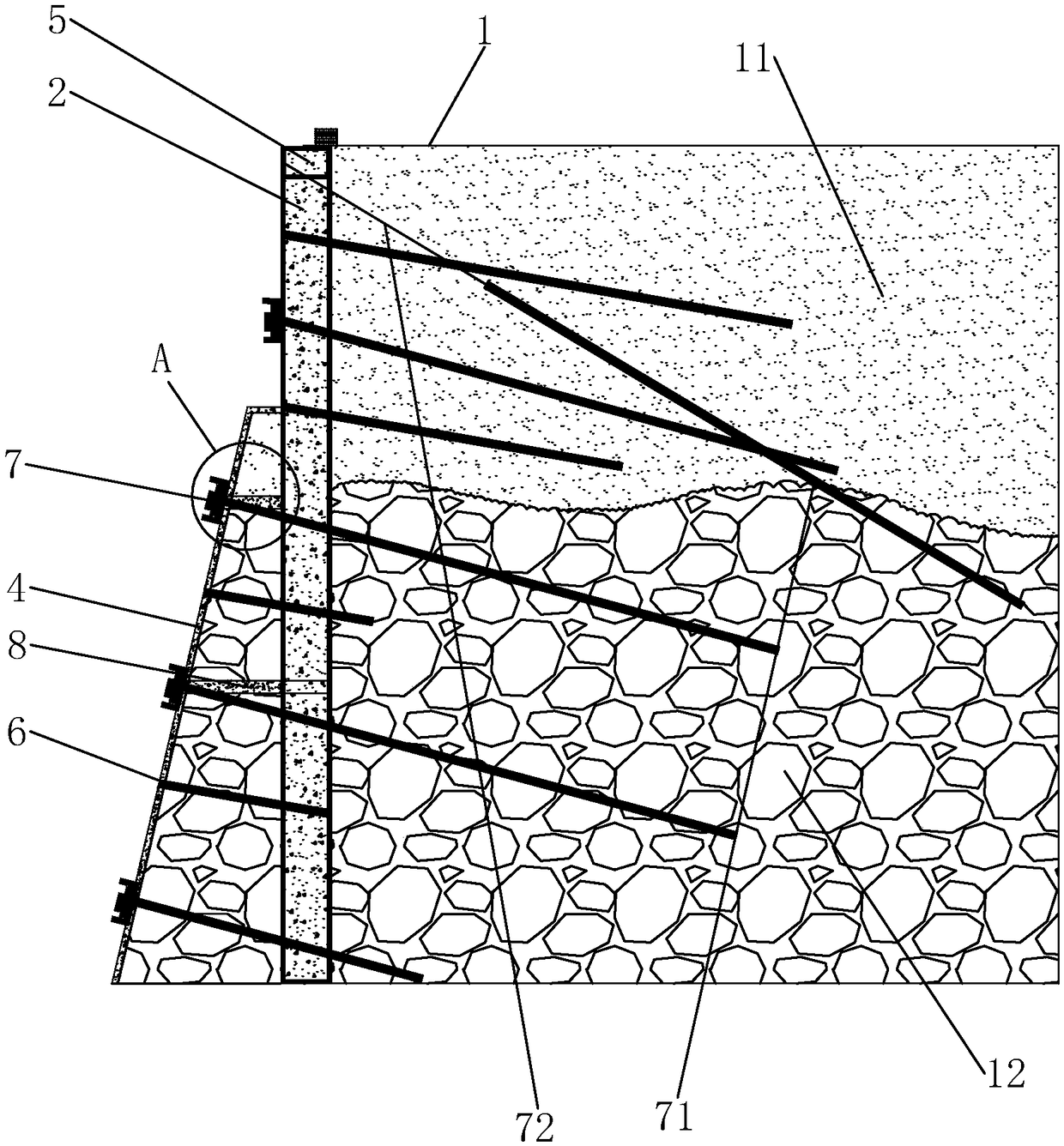

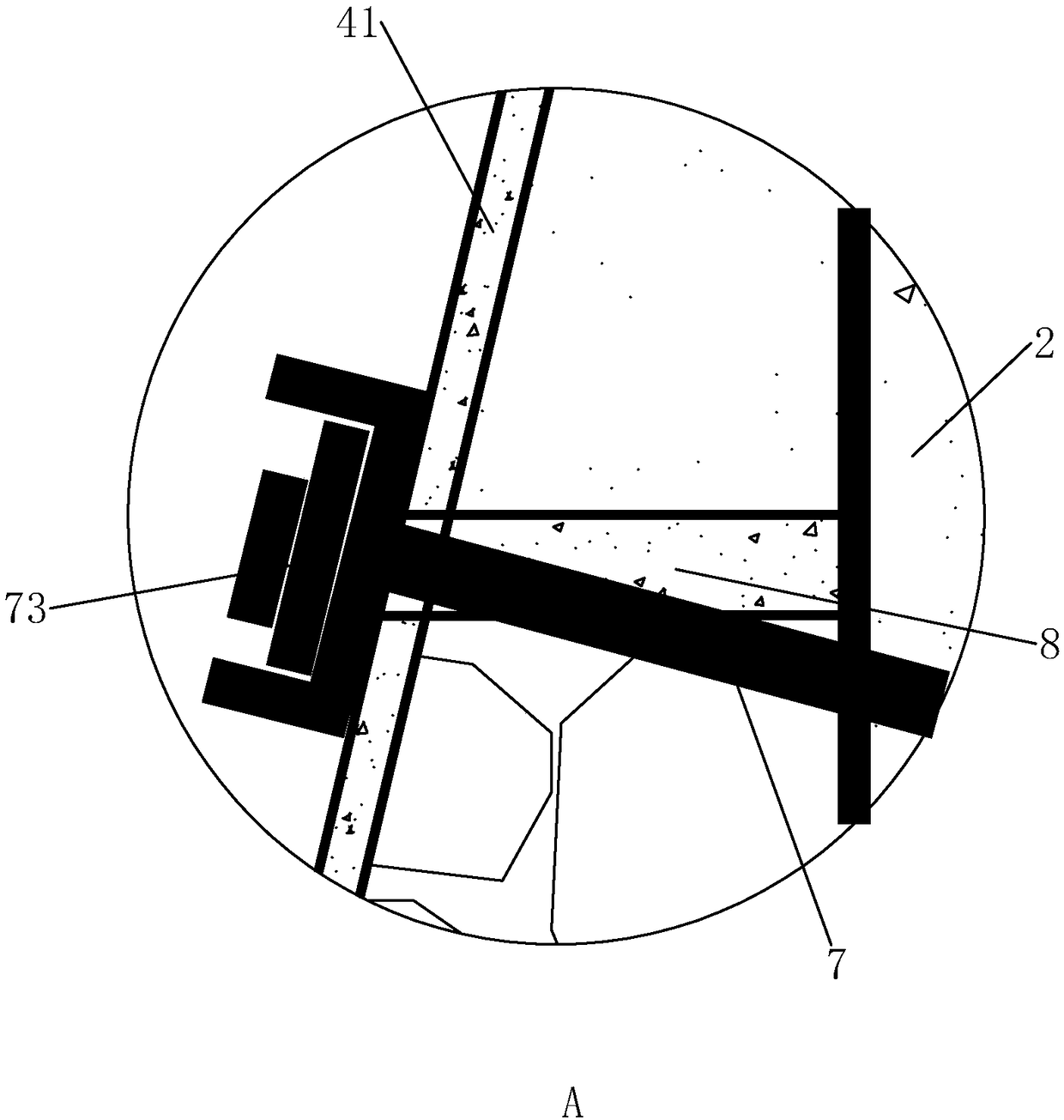

[0030] A composite support structure of composite soil nail wall and pile-anchor support suitable for backfilling, such as figure 1 As shown, it is applied to the side wall of the foundation pit with a deep backfill soil layer 11 under the ground 1, including steel pipe piles 3, slope protection piles 2, soil nail surface walls 41, and prestressed anchor rods 7.

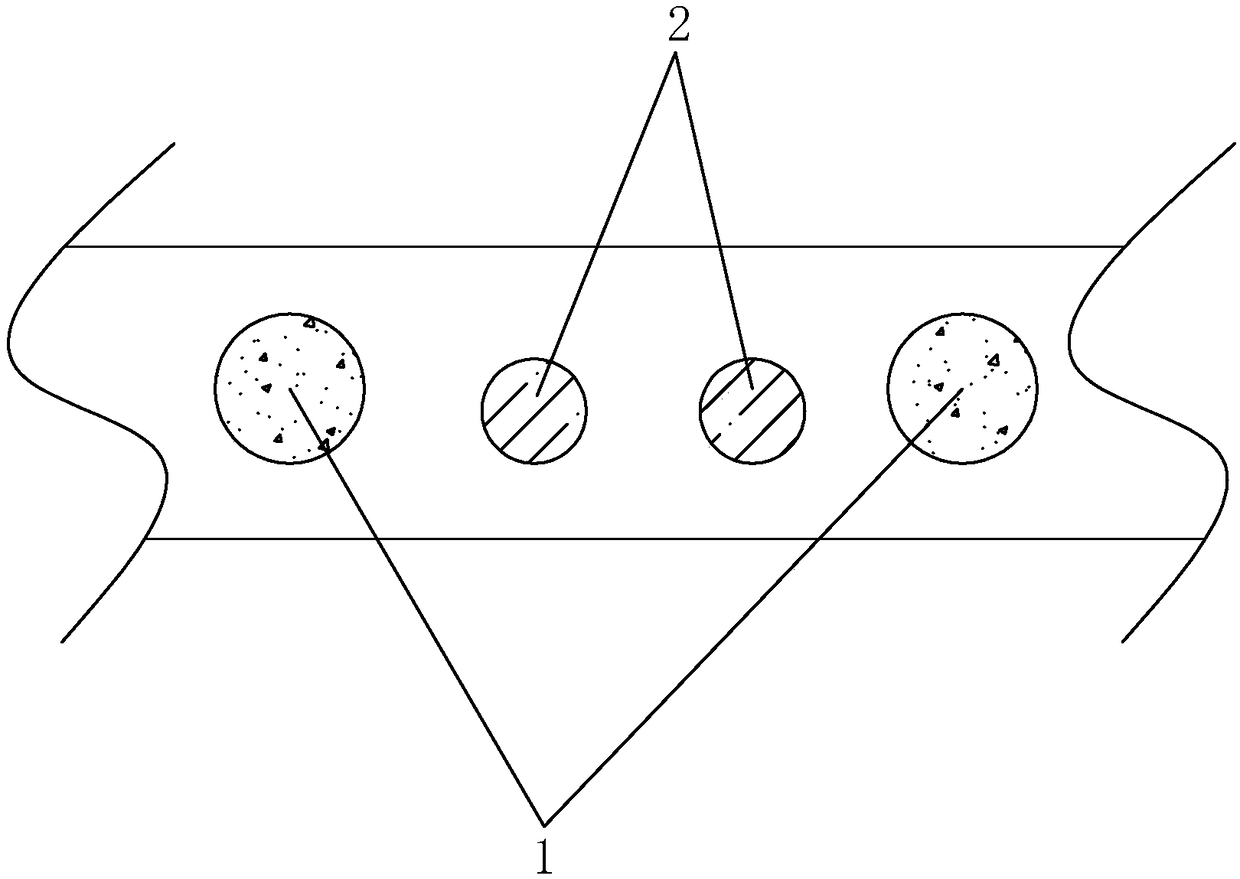

[0031] like image 3 As shown, the slope protection pile 2 is a reinforced concrete pile. In order to increase the retaining capacity of the support system without excessively increasing the cost of the support system, two steel pipe piles 3 are inserted between adjacent slope protection piles 2, and the slope protection pile 2 Together with the steel pipe pile 3, a soil retaining structure is formed. The cost of the steel pipe pile 3 is lower than that of the slope protection pile 2 made of reinforced concrete piles, and its soil retaining capacity can basically meet the soil retaining requirements between adjacent...

Embodiment 2

[0039] A construction method for composite support suitable for deep backfilled soil foundation pits, the steps of which are as follows:

[0040] S1: Excavate the earthwork to the elevation of the construction work surface. According to the depth and distance of the foundation pit designed in the initial stage, drill holes vertically downward from the ground 1 to form several pile holes. Bind the reinforcement cage according to the diameter of the pile holes and lower them into the pile holes. and cast to form reinforced concrete piles;

[0041] S2: Insert one or more steel pipe piles 3 between adjacent reinforced concrete piles depending on the soil layer, and inject cement slurry into the steel pipe piles 3;

[0042] S3: Make a crown beam 5 on the top of all the reinforced concrete piles to connect the tops of all the slope protection piles 2 as a whole, and pass through 3 steel pipe piles, which can be connected by planting reinforcement;

[0043] S4: Insert soil nails 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com