Clutch temperature control method and system for wet type DCT

A temperature control method and clutch technology, applied in the control/adjustment system, mechanical control device, transmission device control, etc., can solve the problems of complex calorie calculation, insufficient comprehensive and accurate judgment of overheating conditions, and low accuracy of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be described in detail below in conjunction with the accompanying drawings.

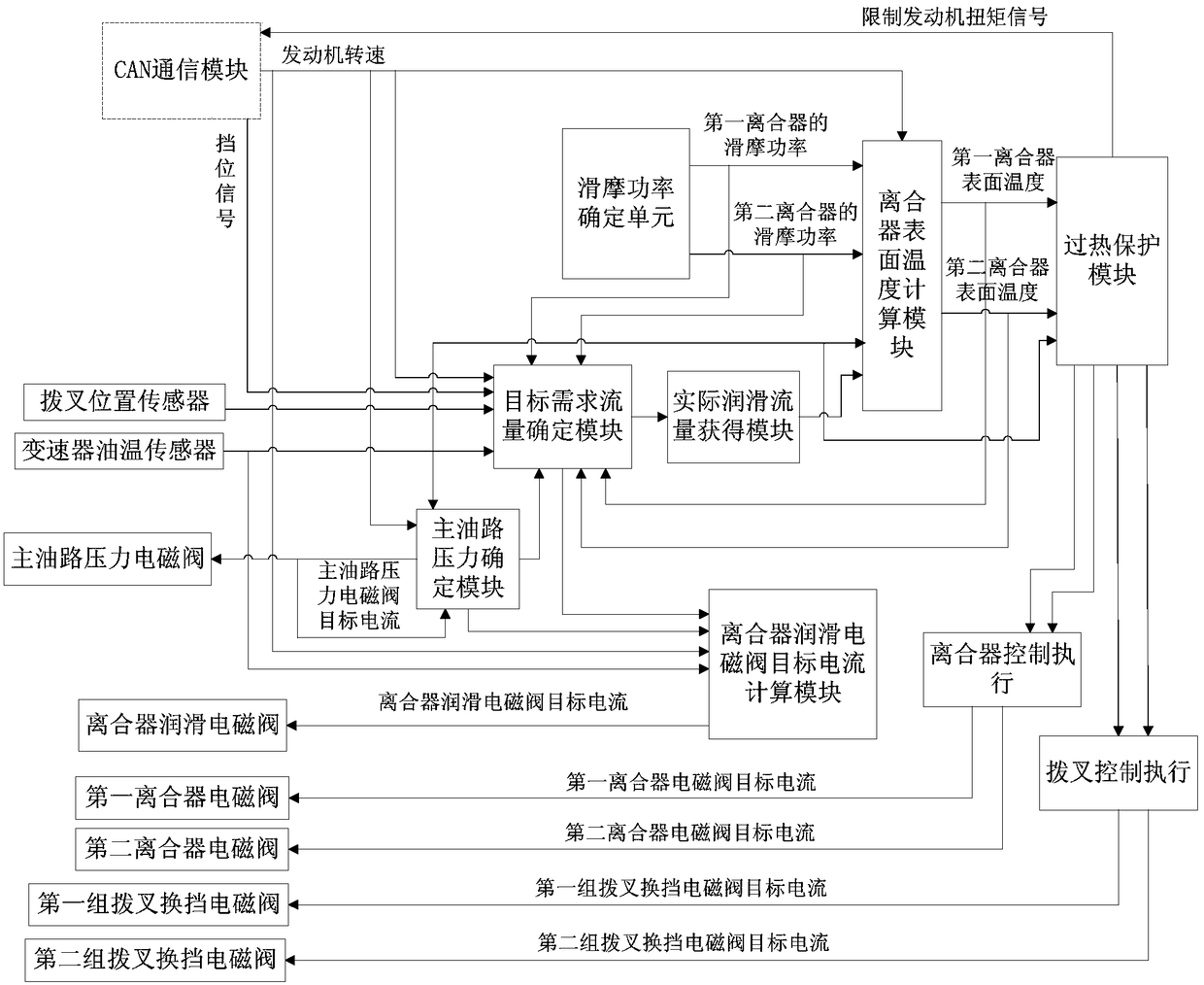

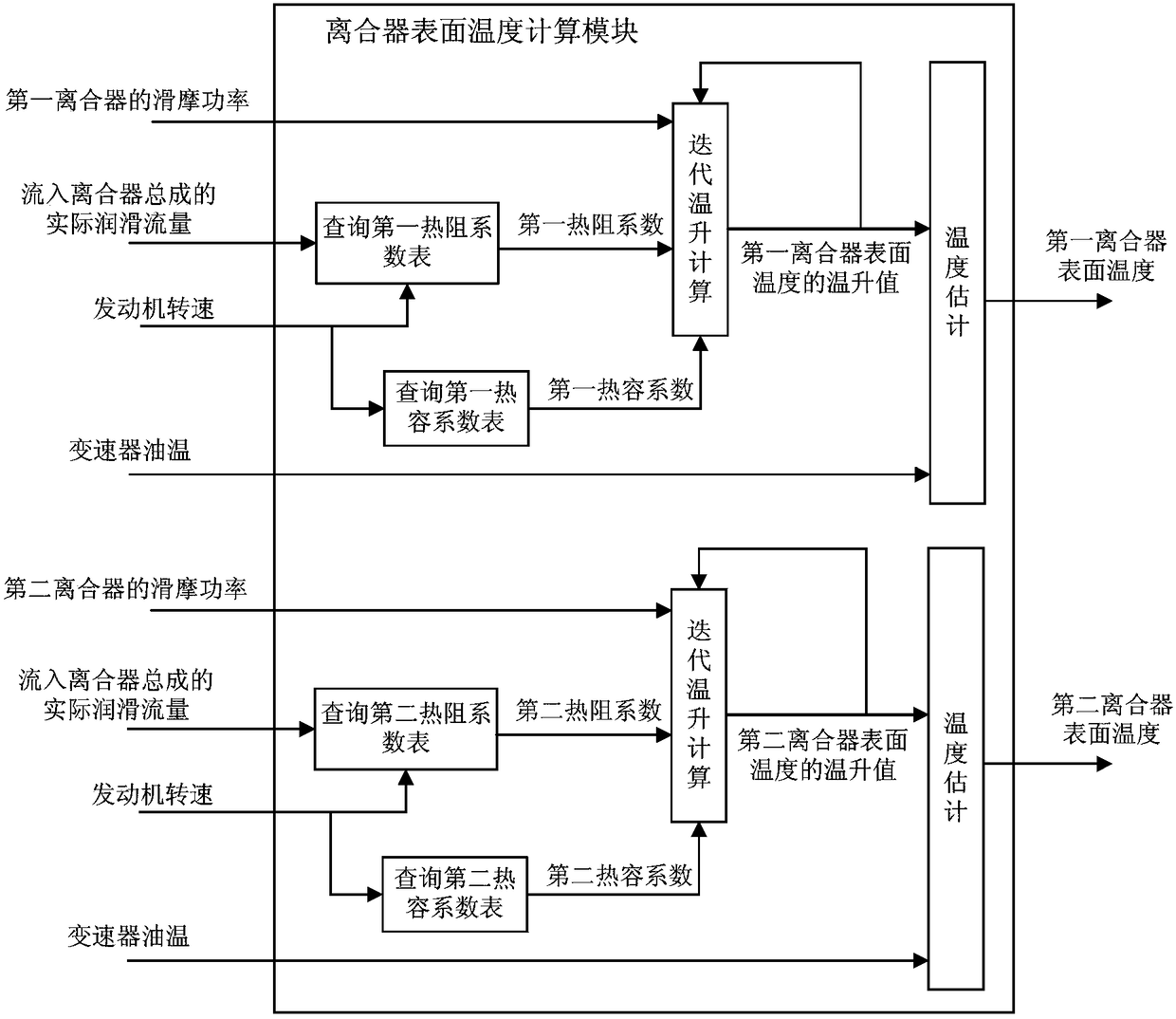

[0079] Such as figure 1 , figure 2 The clutch temperature control methods for the wet DCT shown include:

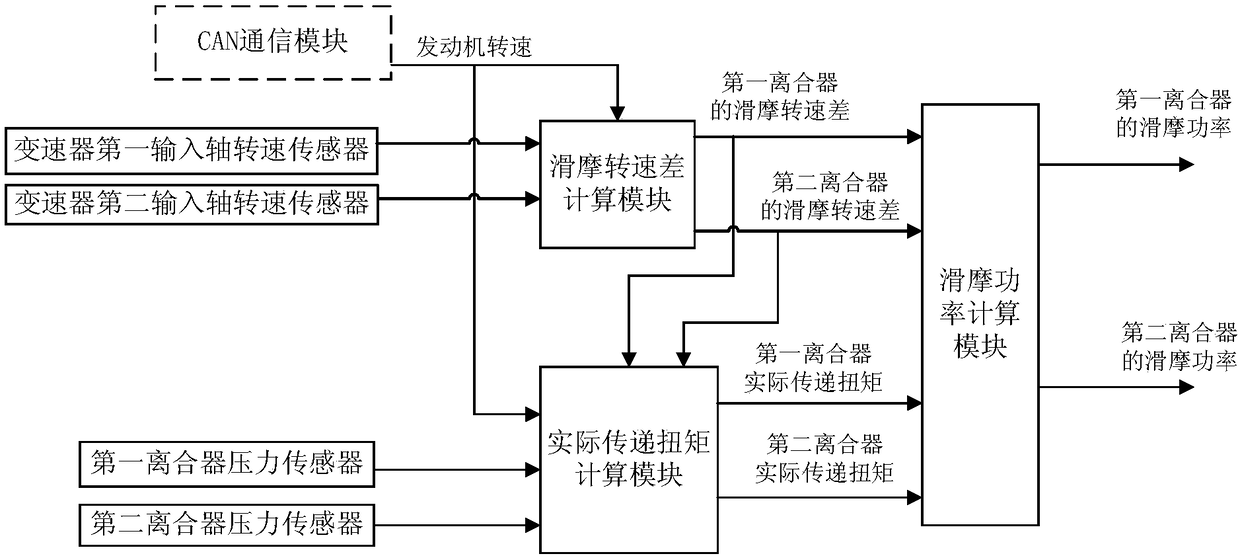

[0080] Collect transmission oil temperature T 3 (corresponding to the oil temperature at the lubrication inlet of the clutch assembly), engine speed, fork position signal, and gear signal to obtain the sliding power of the first clutch, the sliding power of the second clutch and the pressure of the main oil circuit.

[0081] According to transmission oil temperature T 3 , engine speed, fork position signal, gear signal, first clutch surface temperature T 1 , Second clutch surface temperature T 2 , the sliding friction power of the first clutch, the sliding friction power of the second clutch and the pressure of the main oil circuit, determine the target demand flow of the clutch assembly for the lubricating and cooling oil. The wet DCT in this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com