Extrusion test device

A test device and press technology, applied in the field of simulated extrusion devices and extrusion test devices, can solve the problems of difficult adjustment, inconvenient operation, high cost, etc., and achieve the effects of simplifying equipment structure, reducing test cost, and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

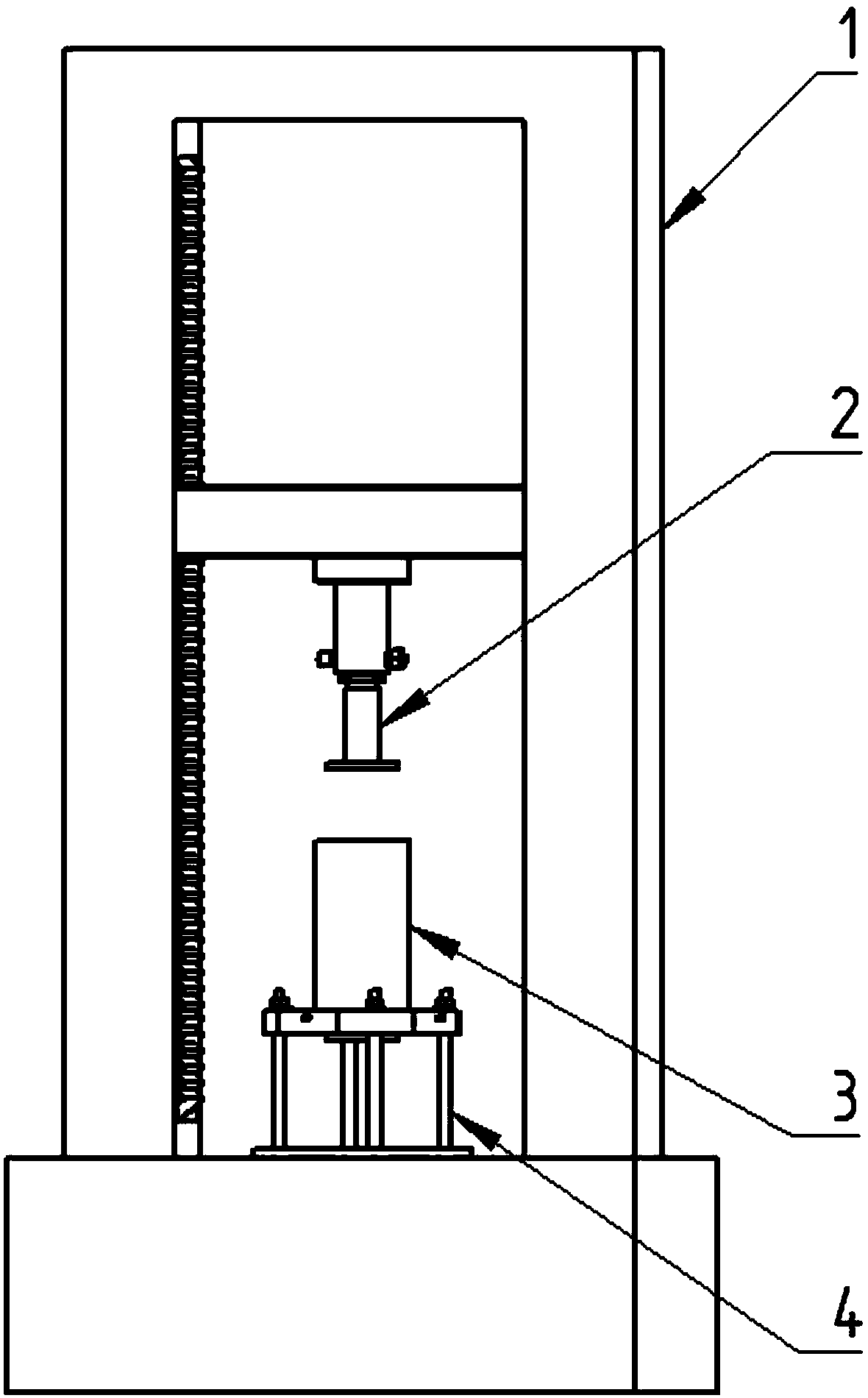

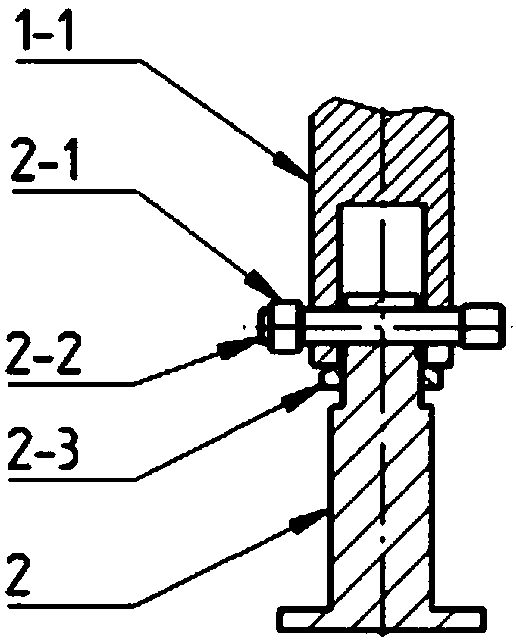

[0029] Such as figure 1 As shown, the present invention mainly includes: pressing shaft 2, guide sleeve 3, fixed base 4, etc., this extrusion test device is connected on the press machine 1, and press machine 1 is the use platform of extrusion test device, and this platform provides A pressure machine interface 1-1 driven by the press machine 1 to move up and down at an adjustable speed, which realizes fixing the pressing shaft 2 on the interface 1-1 of the press machine 1 through a round nut 2-3 and a stop pin 2-2, Such as figure 2 shown. Then the stop pin 2-2 is screwed and fixed on the press interface 1-1 through the nut 2-1. Its working principle is: put the pressing shaft 2 into the interface 1-1, and then put it into the stop pin 2-2. The stop pin 2-2 does not provide any matching size, and its function is to prevent the pressing shaft 2-4 from falling. Finally, the locking of the pressing shaft 2 is realized by tightening the nut 2-1.

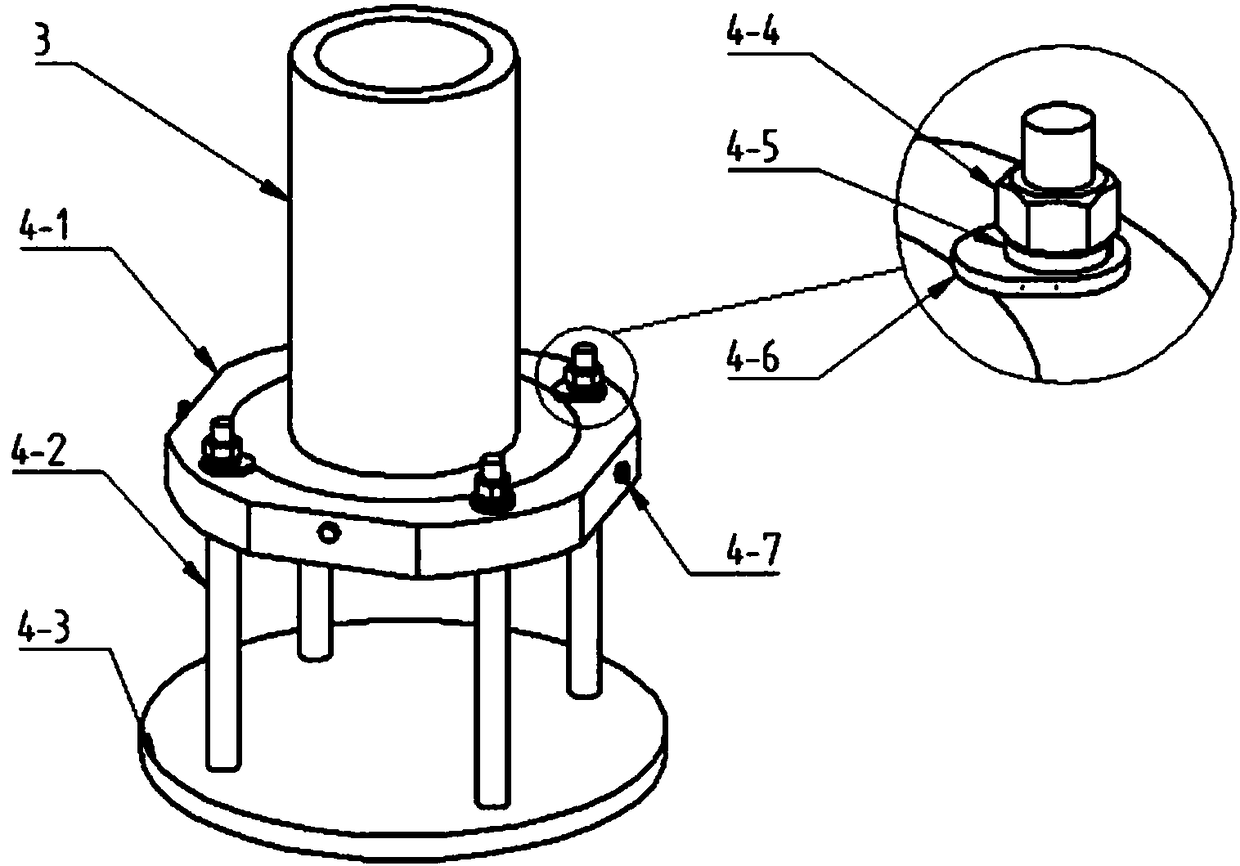

[0030] Such as image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com