Sampling and sample preparation system for cross-double rail train

A sample preparation system and train technology, which are applied in the preparation, sampling, and sampling devices of test samples, can solve the problems of inconvenient centralized operation management, low work efficiency, and low degree of mechanization, and achieve convenient centralized management and fast sampling speed. , the effect of good follow-up performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

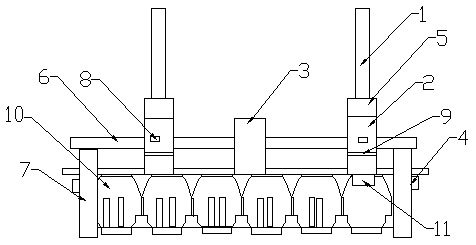

[0013] Such as figure 1 A sampling and sample preparation system across a double-track train is shown, which is characterized in that it includes a lifting device 1, a sampling trolley 2, a sampling motor 5, an operating room 3, a motor 4, a horizontal support frame 6, a vertical support frame 7, and a crusher 8 , divider 9, sample collector 10, PLC controller 11, the middle position of described horizontal support frame 6 is provided with operating room 3, and the two ends sliding of described horizontal support frame 6 are provided with sampling trolley 2, described sampling A crusher 8 is provided below the trolley 2, a shrinker 9 is provided below the crusher 8, a sample collector 10 is provided below the shrinker 9, and a sampling motor is fixed above the sampling trolley 2 5. A lifting device 1 is fixed above the sampling motor 5, and a vertical support frame 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com