Optimum design method for embedded track bed structures of tramcars

An embedded track and tram technology, applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve the problems of late start of research, complicated form of right of way, no unified standard for design and construction, etc. time, improving design efficiency, and the effect of broad engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

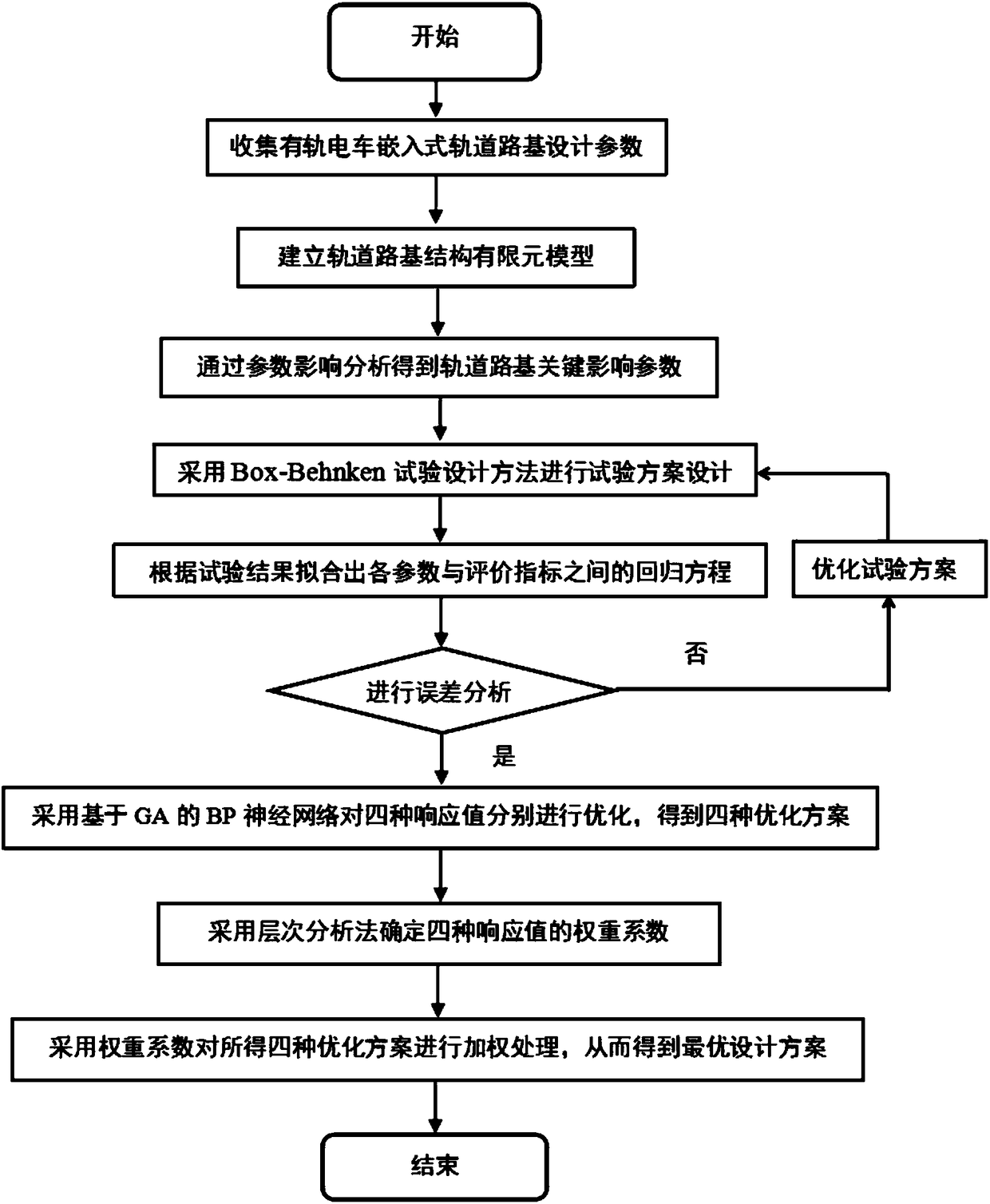

[0037] A kind of simple and convenient method for optimizing the design of embedded track subgrade structure described in this embodiment comprises the following steps:

[0038] Step 1. Fully investigate the design data of the existing tramway subgrade, and basically grasp the design parameters of the tramway subgrade structure. Taking the actual project of a tram as an example, the axle load of the tram is 12.5t, the design speed is 70km / h, the power coefficient is 1.5, the elastic modulus of polymer material is 3MPa, the length of the track slab is 6m, and the width of the track slab is 2.1m, the thickness of the track slab is 0.22m, the width of the support layer is 2.1m, the thickness of the support layer is 0.2m, the total thickness of the subgrade is 1.5m, and the compaction index K 30 It is 110MPa / m.

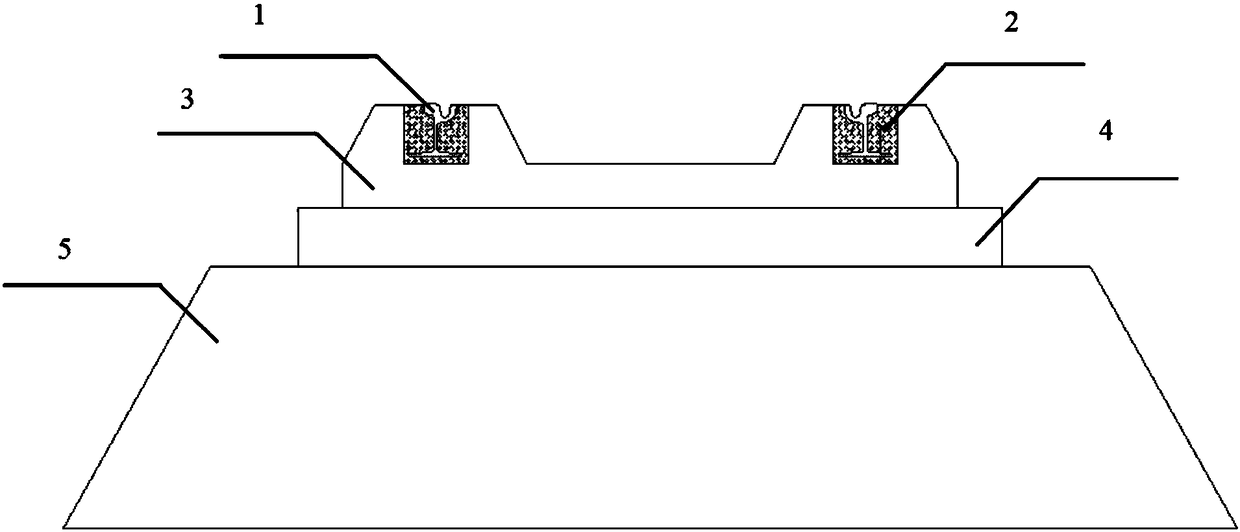

[0039] Step 2, establish the finite element model of tram embedded track subgrade structure according to the track design parameters and subgrade design parameters descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com