Environmental conductive copper and aluminum foil shielding materials for communication cable and manufacturing method thereof

A technology of aluminum foil shielding and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, equipment for manufacturing conductive/semiconductive layers, communication cables, etc., can solve the problems of many electromagnetic signal sources and the shielding performance can not meet the use requirements, etc., to achieve Satisfy the quality requirements, the quality control is convenient and easy, and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

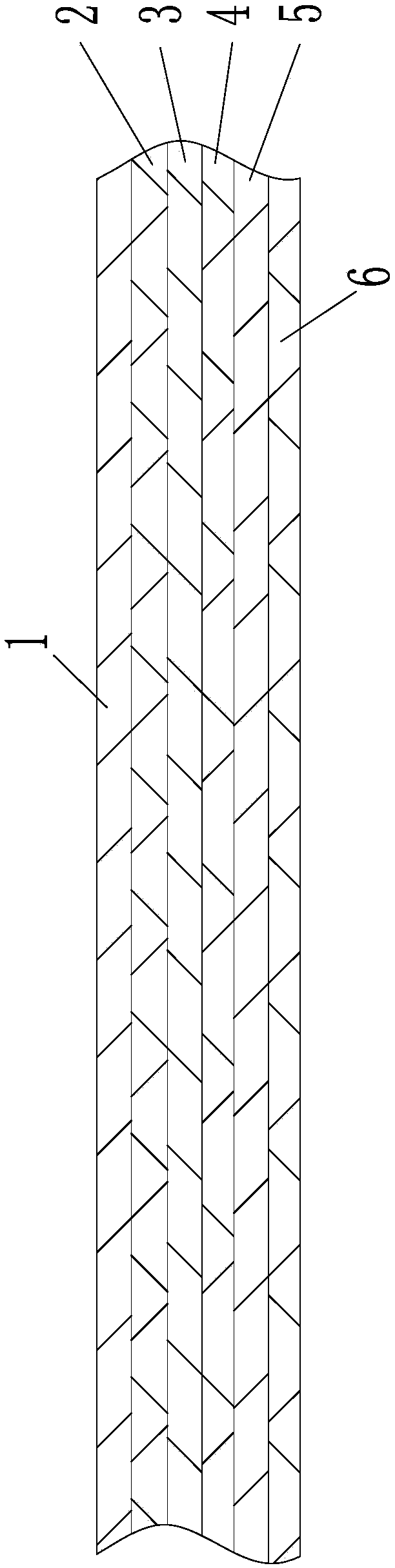

[0024] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0025] figure 1 The communication cable shown uses environmentally friendly conductive copper-aluminum foil shielding material, including an aluminum foil layer; there are two aluminum foil layers, namely the first aluminum foil layer 1 and the second aluminum foil layer 3; the aluminum foil layers are glued to the adjacent The first PET layer 2 bonded together by the aluminum foil layer, wherein the second aluminum foil layer is also bonded with the copper foil layer 5 through the second PET layer 4, and the other outer surface of the copper foil layer is bonded by the EMAA layer of glue 5 (ethylene-methacrylic acid copolymer layer); the EMAA layer acts as a self-adhesive layer in the cable (due to its viscosity at a certain temperature, it can be bonded to the inner surface of the cable sheath layer when the cable sheath layer is injected) .

[0026] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com