Device for converting a pivoting movement of a pinion into a movement in translation of a slide and valve comprising such a device

A technology of pivoting movement and translational movement, applied in the direction of transmission device, valve operation/release device, valve device, etc., can solve the problems of expensive installation and processing, achieve good fit, minimize leakage level, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

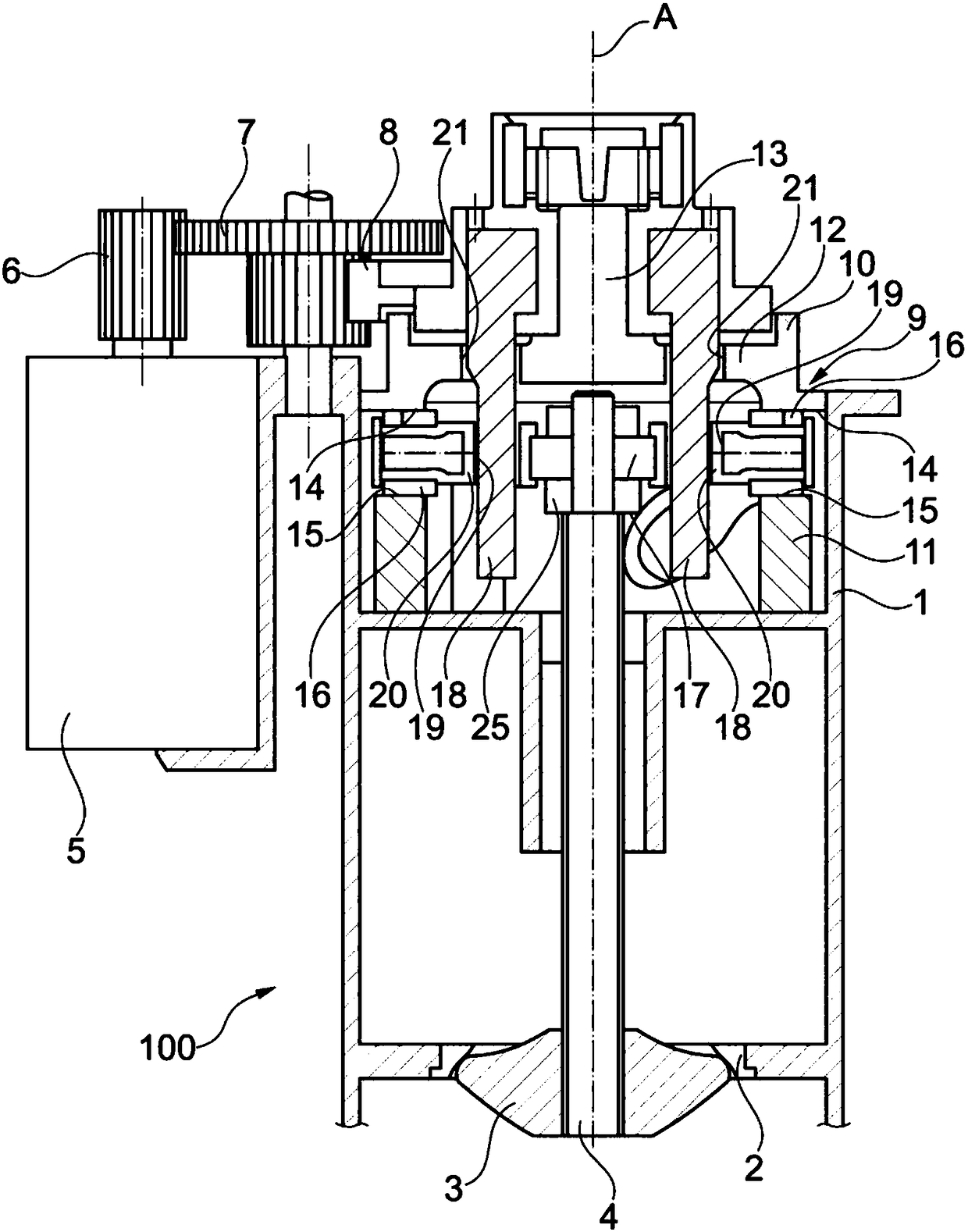

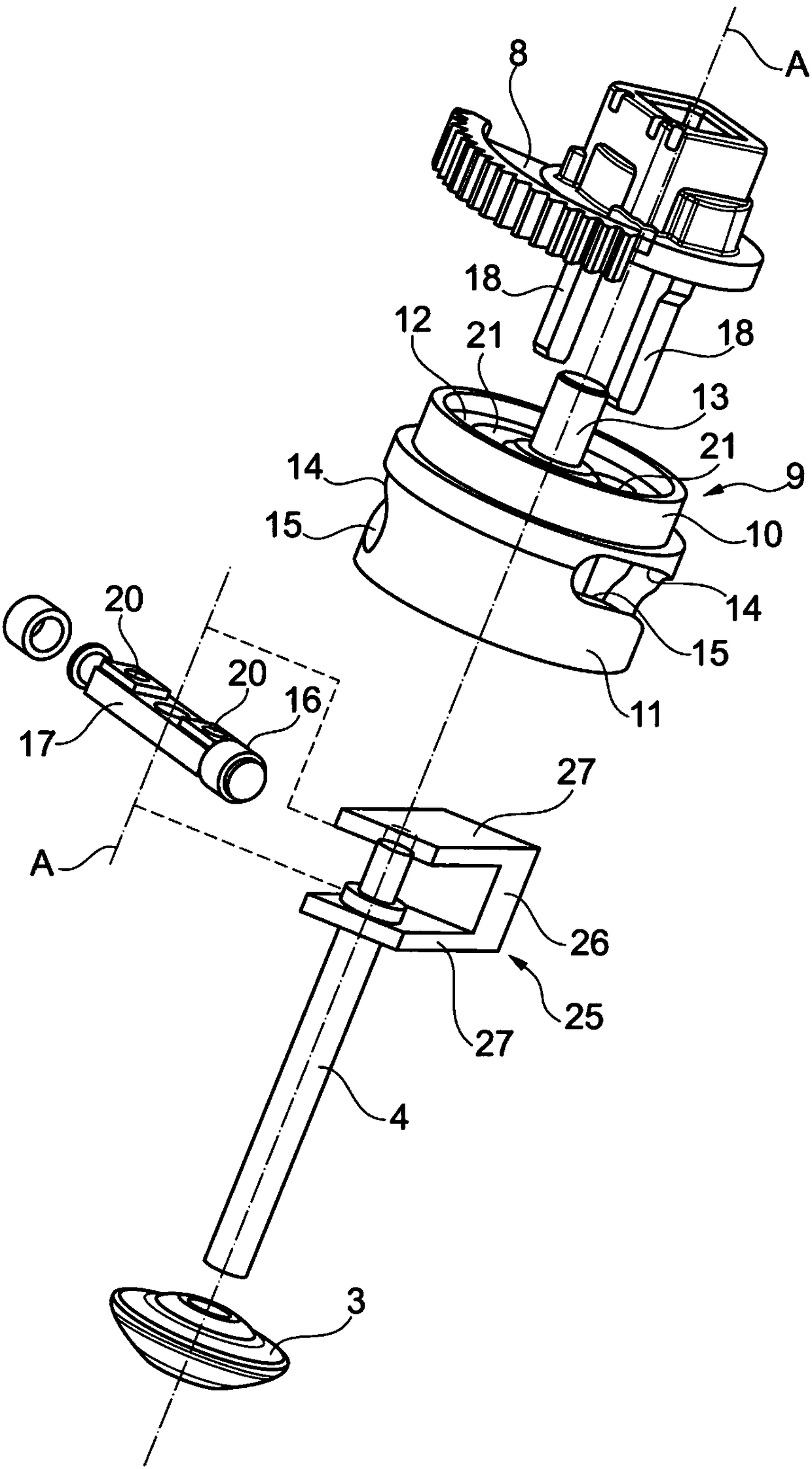

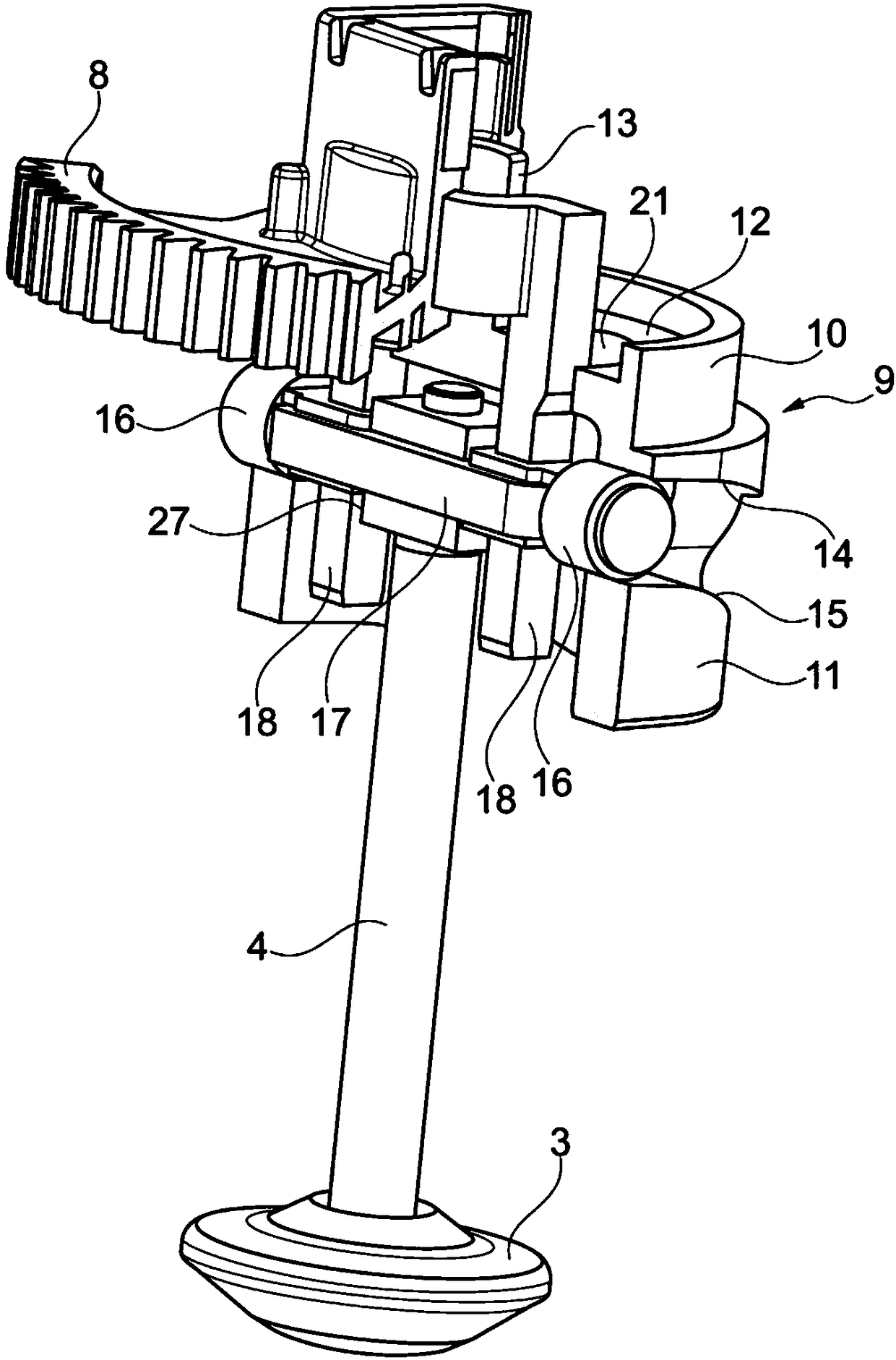

[0028] refer to Figure 1 to Figure 4 , the valve 100 according to the invention comprises a body 1 delimiting a seat 2 for a valve 3 associated with one end of a rod forming a slide 4 mounted in the body 1 in a blocking position In the blocked position, the valve 3 bears against the base 2 and in the open position, the valve 3 is moved away from the base 2 .

[0029] A motor 5 is fixed in the body 1 to drive the slide 4 and thus the valve 3 in translation. The motor 5 has an output pinion 6 which is connected via a gear set 7 to a pinion 8 formed by tooth segments. The gear set 7 is installed on the body 1 . The output pinion 6 , the gear set 7 and the pinion 8 pivot about an axis parallel to the sliding direction A of the slider 4 . The pinion 8 is associated with means generally indicated at 9 for converting the rotational movement of the pinion 8 into a translational movement of the slide 4 .

[0030] The device 9 comprises a support member 10 fixed in the body 1 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com